Marine 3D Printing Services - Custom Marine Spares & Parts

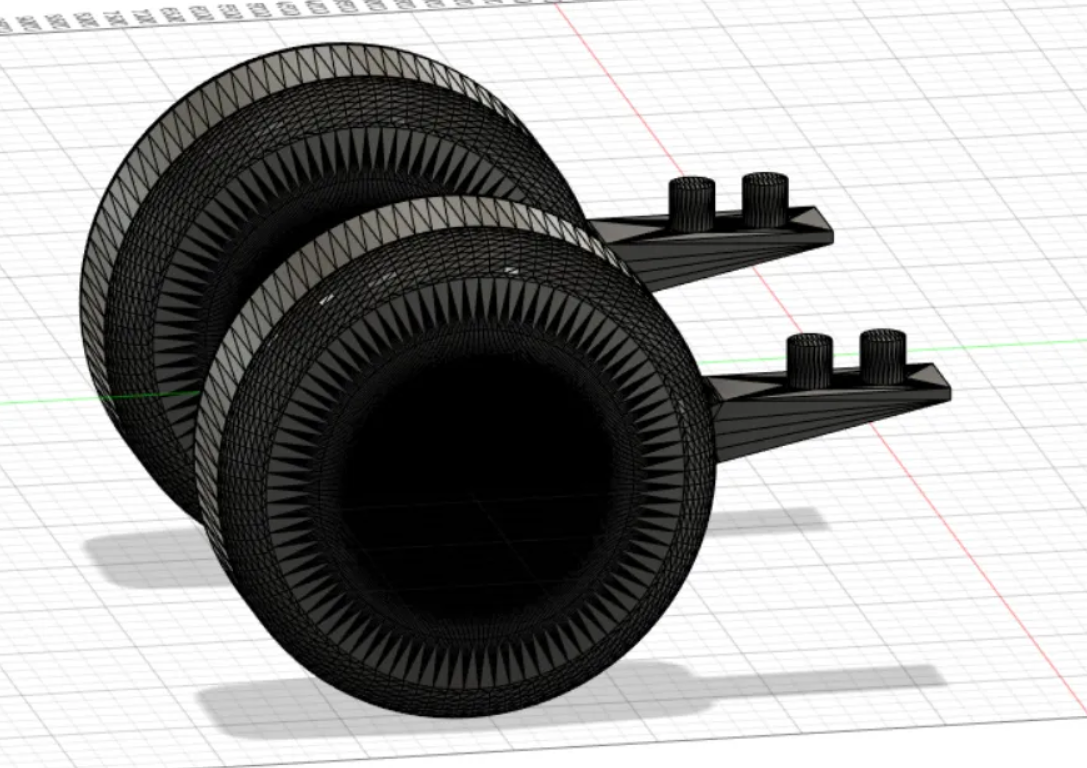

High‑quality 3D printed marine parts and spares ideal for boats, marine equipment, and obsolete components — engineered to withstand demanding sea conditions.

The Marine Spares Parts Industry: Why It Exists, Why It Matters, and Why It Is Unlike Any Other

The marine spares parts industry exists because ships do not have the luxury of failure. When something breaks at sea, it is not an inconvenience—it is a potential operational, financial, and safety crisis. What makes this industry unique is the sheer diversity of vessels, operating environments, and mechanical systems involved. From container ships and tankers to ferries, offshore support vessels, fishing fleets, and naval platforms, no two vessels are ever truly the same. Even sister ships built in the same yard can diverge dramatically over time due to refits, regional regulations, owner preferences, and operational wear. As a result, the marine spares sector has evolved into a highly specialised, experience-driven industry built around knowledge, adaptability, and speed of response. Traditional supply chains struggle here because marine components are often bespoke, obsolete, or produced by manufacturers that no longer exist. That is precisely why this sector has historically relied on long lead times, expensive tooling, and large inventories—because the cost of not having a part when it is needed can far outweigh the cost of holding it. This industry is not about mass production; it is about precision, reliability, and the ability to solve problems under pressure, often with very little notice.

The Hidden Complexity Behind Marine Spare Parts

One of the most misunderstood aspects of the marine spares parts industry is how complex even “simple” components can be. A clip, bracket, housing, or cover might look insignificant on paper, yet its failure can immobilise a system worth millions. Marine parts are exposed to saltwater corrosion, vibration, thermal cycling, UV exposure, chemical contact, and constant mechanical stress. Unlike automotive or consumer industries, marine components are rarely sheltered or gently used. They are pushed hard, day in and day out, often for decades. That is why materials selection, tolerances, and fitment are absolutely critical. A replacement part that is slightly off-spec can accelerate wear elsewhere, introduce vibration, or fail prematurely. Historically, this has meant reverse-engineering by hand, machining from solid stock, or commissioning expensive castings or injection-moulded tooling. These methods work, but they are slow and costly, particularly when only one or two parts are required. This is where the industry’s traditional model begins to show its limitations—and where modern additive manufacturing starts to make real, tangible sense.

Why the Marine Industry Is Ripe for 3D Printing Adoption

The marine sector is uniquely positioned to benefit from 3D printing because its core challenges align perfectly with what additive manufacturing does best. Low-volume production, high part variation, obsolete components, and urgent lead times are all problems that 3D printing was effectively designed to solve. Unlike injection moulding or casting, there is no requirement for expensive tooling. A single part can be designed, validated, and produced without committing to thousands of units. That flexibility is transformative for ship operators, fleet managers, and maintenance teams. It means a broken component does not automatically trigger weeks of downtime or an international sourcing exercise. Instead, a physical sample can be reverse-engineered into CAD, redesigned where necessary to improve strength or longevity, and manufactured in a matter of days rather than months. This is not theory—it is already happening across the industry, quietly replacing legacy workflows that no longer make commercial sense.

How 3D Printing Changes the Economics of Marine Spares

From a financial perspective, 3D printing fundamentally reshapes the cost structure of marine spares. Traditional manufacturing front-loads cost into tooling, setup, and minimum order quantities. This makes sense for thousands of identical parts but becomes wildly inefficient when only one or two are required. Additive manufacturing removes that barrier entirely. The cost is driven primarily by material choice, machine time, and post-processing—not by scale. This means ship owners can justify replacing parts that would previously have been “repaired indefinitely” simply because replacement was too expensive to consider. It also allows for incremental improvements. If a component failed due to a known weakness, it can be redesigned with thicker walls, reinforced geometry, or a more suitable material without retooling an entire production line. Over time, this leads to more robust vessels, lower maintenance costs, and fewer emergency failures. In my view, this is where the real long-term value lies—not just in saving money once, but in systematically improving reliability across a fleet.

Materials Matter: Engineering Plastics and Marine Applications

One of the biggest misconceptions about 3D printing in marine environments is that it is limited to weak or temporary plastics. That simply is not true anymore. Modern engineering materials such as ABS, PETG, ASA, nylon, glass-filled polymers, and carbon-fibre-reinforced filaments are more than capable of handling demanding marine conditions when used correctly. The key is understanding the application. UV exposure, chemical resistance, mechanical load, and operating temperature all dictate material choice. For example, ABS offers excellent strength and durability but is not ideal for prolonged UV exposure. PETG, by contrast, provides better UV stability and a more refined surface finish, making it suitable for external housings or deck-level components. Nylon excels in mechanical strength and wear resistance, making it ideal for moving parts or load-bearing brackets. When combined with 100% infill and proper print orientation, these materials can deliver performance that rivals traditionally manufactured parts—without the associated cost or delay. This material-led, application-first approach is essential, and it is something the marine industry is increasingly beginning to understand and trust.

FAQs

Is Marine suitable for outdoor use?

It depends on UV exposure and heat. Tell us the environment and we’ll advise the best material.

Can you print Marine for functional parts?

Yes. If you share the part purpose and any load/heat details, we’ll confirm the best settings and material choice.