None Critical Elevator Parts

None Critical Parts, printing is the right choice when you need the right balance of performance, finish, and cost for functional parts.

When printing none critical Elevator parts is a sensible choice.

The elevator industry is undergoing a major structural change that will further spur 3D printing innovation.

The big 4 elevator companies, namely Otis, Thyssenkrupp, Kone and Schindler, are increasingly focused on digital business innovation, including 3D printing.

3D printing has the potential to improve supply chain efficiency and reduce costs for both suppliers as well customers, making it a powerful tool in any manufacturer's arsenal.

Reverse engineering services can create an accurate 3d printing file of an out of production or hard to find part. This allows for the easy and on-demand availability of vital spare parts without having to wait for traditional manufacturing methods.

3D printing technology will allow elevator companies to quickly and easily produce the parts they need, without having to worry about inventory levels or lead times.

This will ultimately benefit the customer by reducing downtime and increasing the reliability of elevators. Reverse engineering services will also be a major boon for the elevator industry, as it will allow them to quickly and easily produce the parts they need.

How might 3D printing change the spare parts industry?

3D printing will enable suppliers to increase the availability of spare parts, reduce lead time, and decrease costs. And customers see 3D printing as an opportunity to reduce their own costs and increase the efficiency of their operations. 3D printing is a game changer for both suppliers and customers as it promises to improve availability, reduce costs due increased efficiency in production. 3-dimensional Printing will allow companies access vital spare parts without the hassle of waiting on lengthy shipment times from manufacturers while at same time reducing their own operational expenses through reduced inventory levels or even better yet.

3D printing is a game changer for both suppliers and customers. It promises to improve availability, reduce costs and increase efficiency in production.

For suppliers, 3D printing will enable them to increase the availability of spare parts, reduce lead time, and decrease costs. Customers will also see 3D printing as an opportunity to reduce their own costs and increase the efficiency of their operations.

3D printing is a win-win for both suppliers and customers. Thanks to 3D printing, both groups will be able to improve their businesses and operations.

Elevator & Lift Industry Applications

Modern elevator and lift systems rely on precision, reliability, and long-term serviceability. In an industry where downtime is costly and legacy components are increasingly difficult to source, additive manufacturing offers a practical and commercially sensible solution. At Mitchell & Son Additive Manufacturing, we support the elevator industry by producing high-quality, functional parts that keep systems operational without excessive lead times or tooling costs.

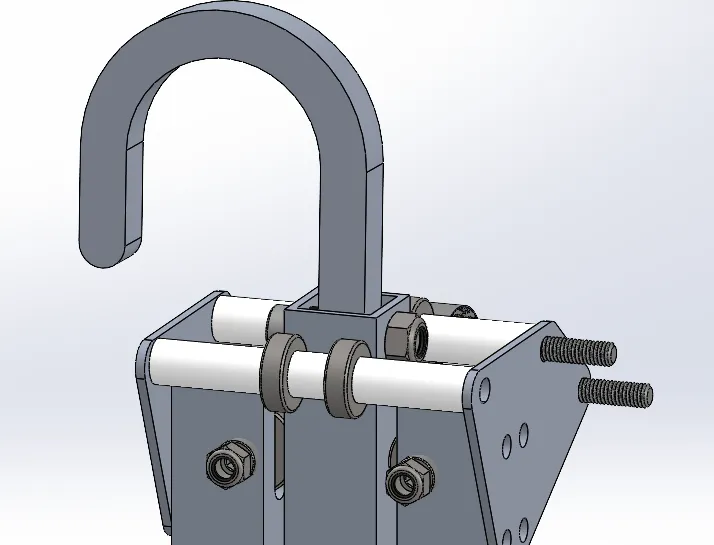

Many elevator installations—particularly older or bespoke systems—contain plastic and composite components that are no longer manufactured. Clips, housings, guides, covers, spacers, and interface components often fail through wear, fatigue, or accidental damage. Traditionally, replacing these parts would involve costly remanufacturing, custom tooling, or full system upgrades. With 3D printing, those barriers are removed.

Using sample parts, drawings, or dimensional measurements, we can reverse-engineer components into accurate CAD models and reproduce them using engineering-grade materials such as ABS, PETG, ASA, or reinforced polymers. Each material is selected based on its real-world application—whether the part needs impact resistance, flexibility, thermal stability, or resistance to UV exposure in lift shafts and plant rooms.

Strength and durability are central to our process. Unlike hobby-grade printing, our components are produced with appropriate infill levels, wall thicknesses, and print orientations to withstand operational forces. Where required, parts can be manufactured with high or full infill to provide structural strength comparable to traditionally moulded components. This ensures the finished item is fit for purpose, not merely a visual replica.

Speed is another key advantage. Elevator maintenance often operates on tight schedules, and delays waiting for parts can result in extended downtime. Additive manufacturing allows us to move from design to production rapidly, reducing lead times from weeks or months to days. For maintenance teams, facility managers, and contractors, this translates directly into cost savings and improved service continuity.

We also offer post-processing options, including sanding, surface finishing, priming, and protective coatings, where appearance or additional durability is required. This is particularly valuable for visible components or parts exposed to repeated handling.

Ultimately, our role is to provide practical manufacturing support to the elevator industry—helping businesses maintain systems efficiently, extend the life of existing installations, and avoid unnecessary replacement costs. Whether producing a single replacement component or a small batch of repeat parts, we focus on delivering reliable, fit-for-purpose solutions that perform in real-world environments.

Precision Manufacturing for Elevator Maintenance & Modernisation

The elevator and lift sector presents a unique manufacturing challenge. Systems are expected to operate safely and reliably over decades, yet many components—particularly non-metal parts—are subject to wear, breakage, or obsolescence. Mitchell & Son Additive Manufacturing works closely with lift engineers, maintenance providers, and facilities teams to address these challenges using precision 3D printing.

One of the most common issues in elevator maintenance is the unavailability of replacement parts. Plastic components used in control interfaces, safety housings, brackets, and mechanical guides are often discontinued long before the system itself reaches the end of its service life. Injection moulding replacements are rarely viable due to tooling costs, minimum order quantities, and long production lead times.

Additive manufacturing removes these constraints. By digitally recreating components in CAD, we can manufacture accurate replacements on demand, without tooling or setup overheads. This approach is particularly effective for low-volume or one-off parts, where traditional manufacturing is neither economical nor practical.

Material choice is critical in elevator applications. Components may be exposed to vibration, repeated mechanical stress, temperature fluctuations, or UV light. We advise on suitable materials at the outset, ensuring each part is manufactured using plastics that meet the operational demands of its environment. Where necessary, alternative materials can be recommended to improve longevity beyond the original design.

Functional strength is engineered into every component we produce. Infill density, layer bonding, and print orientation are carefully considered to ensure parts are not only dimensionally accurate but mechanically robust. For load-bearing or high-movement components, higher infill and reinforced designs are used to enhance durability and performance.

Additive manufacturing also enables iterative improvement. If a part has a known weakness, we can modify the design to strengthen stress points, improve fit, or enhance usability—something that is often impossible with legacy moulded components. This allows elevator operators to move beyond simple replacement and towards incremental system improvement.

In addition to manufacturing, we offer finishing services where required. This includes smoothing, priming, sealing, or reinforcing parts to meet aesthetic, handling, or environmental requirements. These options are particularly valuable where components are visible to users or subject to frequent interaction.

Our approach is straightforward: understand how the part is used, design it properly, manufacture it correctly, and deliver a solution that works in the real world. By combining technical knowledge with practical manufacturing experience, we help the elevator industry reduce downtime, control costs, and keep essential systems running safely and efficiently.

FAQs

Is Elevator suitable for outdoor use?

It depends on UV exposure and heat. Tell us the environment and we’ll advise the best material.

Can you print Elevator for functional parts?

Yes. If you share the part purpose and any load/heat details, we’ll confirm the best settings and material choice.