PET 3D Printing Material UK | Lightweight & Durable Prints

PET filament for lightweight, heat‑resistant 3D printed components suitable for functional prototypes and engineered parts

PET – Industrial-Grade 3D Printing for Lightweight, Moisture-Resistant Parts

PET is the base material used to make PETG, but it’s not the same thing. If you want something that's a bit stiffer, less prone to oozing during print, and offers excellent moisture resistance, PET might be what you're after. It’s got decent strength, prints well under the right conditions, and it doesn’t soak up water like Nylon does.

I don’t reach for PET every day, but for jobs where you want a clean finish, low warping, and good strength for internal-use components, it can be spot-on. Especially if someone wants a balance between affordability and functionality — this material lands right in the middle.

Key Technical Specifications (Typical Values)

• Tensile strength: 50–60 MPa • Elongation at break: 15–25% • Heat deflection temperature: 70–80°C • Density: ~1.38 g/cm³ • Chemical resistance: Good (oils, grease, mild acids) • UV resistance: Moderate • Impact strength: Moderate • Surface finish: Smooth, with slight gloss

Where PET stands out is in its low moisture absorption — meaning you don’t need to dry it constantly like Nylon. That makes it ideal for low-maintenance workshop setups or parts going into humid environments.

PET Plastic Filament — Understanding What Makes It Different

PET plastic filament, most commonly encountered in the 3D-printing world as PETG (Polyethylene Terephthalate Glycol-modified), sits in a very particular and useful position between standard consumer plastics and true engineering-grade materials. PET itself is not a new material. It is the same polymer family used in drinks bottles, food packaging, and medical containers, which immediately tells you something important: it is stable, predictable, chemically resistant, and well understood at an industrial level. What makes PET filament unique in additive manufacturing is how those proven properties translate into printed parts that balance strength, flexibility, surface finish, and environmental resistance in a way few other filaments can.

Unlike PLA, which is easy to print but brittle and heat-sensitive, PET offers real mechanical resilience. Unlike ABS, which is strong but temperamental and UV-sensitive, PET remains dimensionally stable, less prone to warping, and far more tolerant of outdoor environments. PETG, in particular, adds glycol to the base PET polymer, which improves layer adhesion and reduces crystallisation during cooling. In practical terms, this means parts are tougher, less likely to crack along layer lines, and far more forgiving during printing.

From my perspective, PET filament is one of those materials that genuinely earns its place in professional workflows. It is not a “beginner plastic,” nor is it over-engineered for the sake of it. It exists because it solves real problems: parts that need to live outside, parts that must flex slightly without snapping, parts that are handled daily, cleaned, or exposed to moisture. That balance is why PET has quietly become one of the most relied-upon materials for functional, real-world 3D printing rather than just prototyping.

Why PET Filament Matters in Real-World Manufacturing

What makes PET particularly important is not just what it is, but what it replaces. Traditionally, when a component failed and could not be sourced, the only viable route was injection moulding or machining. Injection moulding, while excellent at scale, carries heavy upfront tooling costs. For small batches, legacy components, or discontinued parts, this becomes commercially unrealistic very quickly. PET filament enables a different approach: low-volume, on-demand manufacturing using a material already trusted in mass production.

PET’s chemical resistance is one of its understated strengths. Oils, greases, cleaning agents, mild acids, and alkalis that would attack PLA or degrade ABS over time have minimal effect on PET. This makes it extremely suitable for parts used in workshops, marine environments, food-handling areas, and medical settings. Add to this its low moisture absorption compared to nylon, and you have a filament that behaves predictably both during printing and in service.

There is also the matter of surface finish. PETG naturally produces a semi-gloss to glossy finish without post-processing. This is not cosmetic alone. A smoother surface reduces dirt adhesion, makes cleaning easier, and improves wear characteristics where parts slide against one another. In many applications, PETG parts come off the printer already fit for purpose, saving both time and cost.

From a sustainability angle, PET deserves recognition as well. Being part of the PET recycling stream means waste management and recycling pathways already exist. While 3D-printing filament recycling is still developing, PET as a base polymer aligns far better with existing infrastructure than many exotic filaments.

How 3D Printing with PET Creates Tangible Benefits

The real benefit of PET in 3D printing is not theoretical — it is practical and measurable. First, there is speed. A part can be designed, printed, tested, modified, and re-printed within days or even hours. PET’s forgiving print behaviour reduces failed prints, meaning less wasted material and less downtime. For businesses, that translates directly into cost savings.

Second, there is performance. PET parts can be printed with high infill densities when strength is critical or lower infill for lightweight components, without the brittleness penalty seen in PLA. At 100% infill, PET produces parts that are impressively tough, capable of handling vibration, repeated movement, and moderate impact loads. This is particularly valuable for brackets, clips, housings, guards, and mechanical interfaces.

Third, PET supports customisation. Every part can be dimensionally adjusted without new tooling. That flexibility is invaluable when retrofitting parts to older machinery, heritage vehicles, rail equipment, marine systems, or bespoke installations. Instead of compromising with “close enough,” PET allows the part to be right.

Finally, PET enables local manufacturing. Parts can be produced where they are needed, reducing lead times, shipping costs, and dependency on overseas suppliers. For small businesses, maintenance teams, and restoration projects, this decentralised approach can be the difference between downtime and continuity.

Technical Properties of PET Filament

From a technical standpoint, PET filament offers a well-balanced set of mechanical and thermal properties that make it suitable for functional use:

Tensile strength: Typically 45–55 MPa

Flexural strength: Around 70–80 MPa

Elongation at break: 20–25% (significantly higher than PLA)

Glass transition temperature (Tg): ~80°C

Printing temperature: 230–260°C

Bed temperature: 70–90°C

Density: ~1.27 g/cm³

UV resistance: Good (far superior to ABS)

Chemical resistance: Excellent against oils, greases, and mild solvents

These figures matter because they translate directly into performance. PET does not suddenly soften in a warm car like PLA, nor does it become brittle after prolonged sunlight exposure like ABS. It retains impact resistance over time and maintains layer integrity under cyclic loading, which is critical for parts that move or flex.

Layer adhesion is another key technical advantage. PETG bonds extremely well between layers, reducing anisotropy — the weakness along layer lines that plagues many printed parts. This makes PET more predictable under load, which is essential when printing functional components rather than decorative objects.

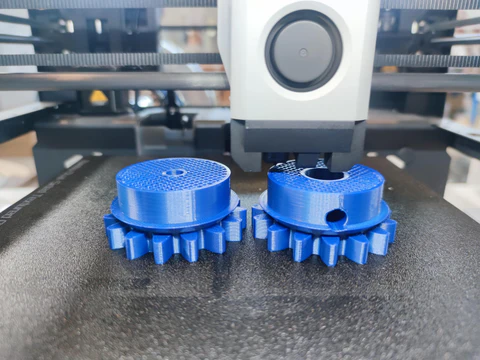

A Real-World Application: Replacing Obsolete Mechanical Components

One practical example that illustrates PET’s value perfectly is the replacement of obsolete mechanical clips and control components in legacy equipment. When original plastic parts fail — often due to UV degradation or age — replacements are rarely available. Injection moulding a handful of parts is financially unjustifiable, and machining plastic equivalents often compromises geometry and flexibility.

Using PET filament, a worn or broken component can be reverse-engineered, modelled in CAD, and printed with the appropriate infill and wall thickness to match or exceed the original part’s performance. PET’s durability ensures the replacement will not only function but outlast the original, particularly in outdoor or high-use environments.

The cost difference is stark. Instead of thousands in tooling and setup costs, the entire process — design, printing, and finishing — can often be achieved for a few hundred pounds. The result is not a prototype but a working, production-grade part.

In my professional opinion, PET filament represents one of the most sensible material choices available in modern 3D printing. It does not shout for attention, but it consistently delivers. When a customer needs something that works in the real world — not just on a desk — PET is often the material that quietly solves the problem. That, ultimately, is what good engineering materials are meant to do.

FAQs

Is Pet suitable for outdoor use?

It depends on UV exposure and heat. Tell us the environment and we’ll advise the best material.

Can you print Pet for functional parts?

Yes. If you share the part purpose and any load/heat details, we’ll confirm the best settings and material choice.