ASA 3D Printing Material UK | UV‑Resistant Outdoor Durable Parts

ASA engineering plastic for strong, UV‑stable 3D printed parts — great for outdoor and weather‑exposed applications with long‑lasting performance.

ASA Filament: What It Is and Why It Exists

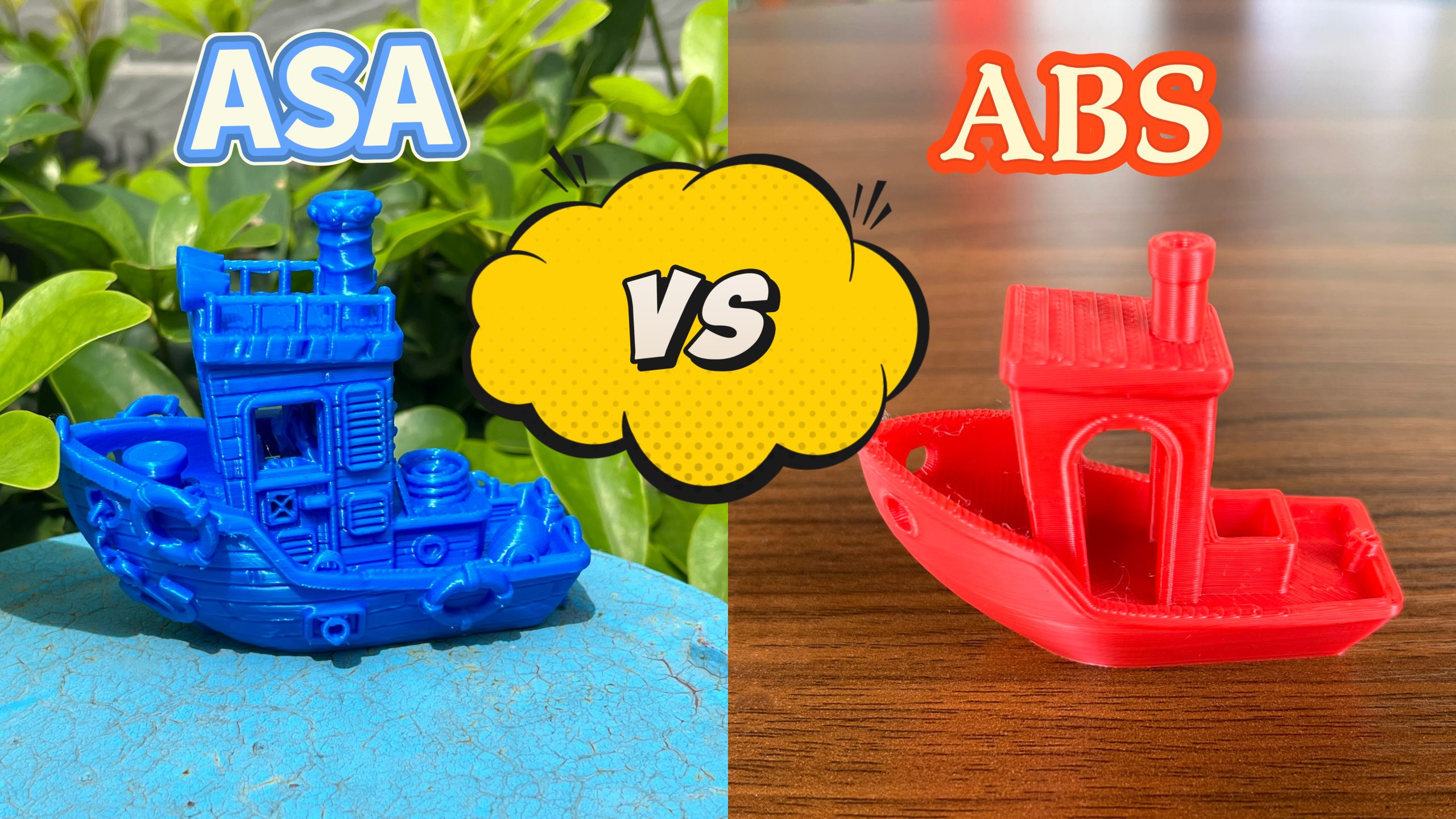

ASA filament, short for Acrylonitrile Styrene Acrylate, exists for one very specific reason: to solve the long-standing weaknesses of ABS while keeping its strengths. Anyone who has worked with ABS for years knows exactly what those weaknesses are. ABS is tough, impact resistant, and dimensionally stable, but the moment you put it outdoors or expose it to UV light for long periods, it starts to fail. It becomes brittle, fades, and eventually cracks. ASA was developed to address that exact problem.

From a chemical standpoint, ASA replaces the butadiene rubber found in ABS with an acrylate rubber. That single change dramatically improves UV stability and weather resistance without sacrificing mechanical performance. In real terms, this means ASA parts can sit outside for years, exposed to sunlight, rain, temperature swings, and pollution, without degrading in the way ABS inevitably will. That is not marketing talk; it is a material science reality.

What makes ASA genuinely valuable is that it behaves like an engineering plastic rather than a hobbyist material. It is not designed for ornaments or decorative prints. It is designed for components that do a job. Brackets, housings, enclosures, clips, covers, jigs, fixtures, and functional replacements are where ASA shines. If a customer comes to me needing a part that will live outdoors, near a window, inside a vehicle, or in an industrial environment, ASA is one of the first materials I will consider.

Another reason ASA exists is consistency. When printed correctly, ASA produces predictable mechanical properties. That matters in real-world applications where tolerances, strength, and reliability are non-negotiable. ASA is not as forgiving as PLA, but that is the point. It is a professional material intended for professional outcomes.

From a business and manufacturing perspective, ASA bridges a critical gap. Injection moulding with ASA is expensive and tooling costs are high. With 3D printing, those same material properties become accessible at low volume, short lead times, and a fraction of the cost. That is where ASA becomes commercially powerful, not just technically impressive.

In simple terms, ASA exists because industries needed an outdoor-ready, UV-stable, structurally reliable plastic that could be produced quickly without committing to expensive tooling. And 3D printing is what unlocked that potential.

What Makes ASA Unique Compared to Other Filaments

ASA is often described as “ABS for outdoors,” but that description barely scratches the surface. What truly makes ASA unique is the balance it strikes between mechanical strength, environmental resistance, and long-term stability.

Let us start with UV resistance. PLA fails almost immediately outdoors. ABS lasts longer but degrades steadily. PETG holds up reasonably well but softens under heat and mechanical load. ASA, on the other hand, is engineered to resist ultraviolet radiation at a molecular level. That means colour stability, surface integrity, and mechanical strength remain consistent over time.

Heat resistance is another defining feature. ASA has a glass transition temperature of around 100–105°C, placing it firmly in the engineering category. This makes it suitable for environments where PLA and PETG simply cannot survive, such as near engines, electronics, or sun-exposed housings. A black ASA enclosure mounted outdoors in summer will not soften and deform the way lower-temperature plastics will.

ASA also offers excellent chemical resistance. It stands up well against oils, greases, fuels, cleaning agents, and mild acids. That matters in automotive, marine, industrial, and maintenance environments where plastics are routinely exposed to substances that would quickly degrade lesser materials.

Surface finish is another often overlooked advantage. ASA prints with a naturally smooth, matte finish that looks professional straight off the printer. It does not have the cheap, glossy look of PLA, nor does it suffer from the uneven sheen common with poorly printed ABS. This makes ASA ideal for visible components where aesthetics still matter.

Dimensional stability is also critical. ASA shrinks less than ABS and warps less when printed correctly in an enclosed environment. That means better tolerances, better fit, and fewer failed prints. From a production standpoint, that reliability translates directly into lower costs and faster turnaround.

In short, ASA is unique because it does not compromise. It is not the easiest filament to print, but it rewards correct setup with results that are genuinely industrial in nature. That is why ASA is used extensively in automotive trim, outdoor signage, electrical enclosures, and infrastructure components.

How 3D Printing with ASA Delivers Real Benefits

The real power of ASA is unlocked when it is paired with 3D printing. This is where theory turns into practical value.

Traditional manufacturing methods such as injection moulding demand high upfront investment. Tooling alone can run into thousands of pounds before a single part is produced. That model makes no sense for low-volume, replacement, or bespoke components. With 3D printing, ASA parts can be produced on demand, with no tooling, no long lead times, and no minimum order quantities.

For businesses, this changes everything. Instead of holding stock that may never be used, parts can be printed when needed. Instead of scrapping assemblies because a small plastic component has failed, that component can be reproduced, improved, and reinstalled.

ASA is particularly well suited to this model because it produces end-use parts, not prototypes. When printed at high infill levels and with correct layer orientation, ASA components can handle real mechanical loads, vibration, and environmental exposure. This is not theoretical strength; it is strength proven in service.

Another benefit is design freedom. With 3D printing, parts can be redesigned to be stronger than the original. Stress points can be reinforced, wall thickness adjusted, and features added that would be impossible or prohibitively expensive with traditional moulding. ASA supports this perfectly because it responds well to structural design improvements.

Speed is another advantage. A replacement ASA part can often be designed, printed, and installed within days rather than weeks or months. For industries where downtime costs money, that speed is not a luxury; it is a necessity.

Finally, there is cost control. By adjusting infill, wall thickness, and print orientation, parts can be optimised for strength without wasting material. Customers are not paying for unnecessary plastic; they are paying for performance where it is needed.

In practical terms, 3D printing with ASA allows businesses to move from reactive replacement to proactive improvement. Parts are no longer just copied; they are engineered to be better.

Technical Properties of ASA Filament (

ASA’s technical profile is what elevates it into the engineering category.

Tensile strength: typically 45–55 MPa

Flexural strength: around 70–90 MPa

Impact resistance: high, comparable to ABS

Glass transition temperature: ~100–105°C

UV resistance: excellent, designed for long-term outdoor exposure

Chemical resistance: good resistance to oils, fuels, greases, and cleaning agents

Density: ~1.07 g/cm³

Printing parameters are equally important. ASA generally prints between 240–260°C with a heated bed at 90–110°C. An enclosed printer is strongly recommended to prevent warping and layer separation. Cooling should be minimal, as rapid cooling can introduce internal stresses.

Layer adhesion in ASA is strong when temperature control is correct. This makes it suitable for load-bearing components, particularly when printed with higher infill percentages or solid walls.

Post-processing is another area where ASA performs well. It can be sanded, machined, drilled, and bonded. Vapour smoothing is possible, producing injection-mould-like finishes when required.

These technical characteristics explain why ASA is trusted in environments where failure is not an option.

Real-World Application: Outdoor Mechanical Components

One of the most common real-world applications for ASA is outdoor mechanical components. These are parts that must survive sun, rain, frost, vibration, and physical load simultaneously.

A typical example is an outdoor control housing. ABS versions of these housings often crack or fade within a few years. ASA replacements, printed with reinforced wall sections and proper infill, can last significantly longer without degradation.

Another real-world use is automotive exterior trim and brackets. ASA is widely used in this sector because it maintains strength and appearance even when exposed to engine heat and UV radiation.

In rail, marine, and infrastructure projects, ASA is often used for clips, covers, cable guides, and protective housings. These are parts that are expensive to tool but critical to operation. 3D printing allows them to be replaced quickly and improved where necessary.

This is where ASA and 3D printing together become not just a manufacturing method, but a problem-solving tool.

Why Buyers Choose ASA

ASA is one of the most under-appreciated filaments in additive manufacturing. It is not glamorous, and it is not beginner-friendly, but when reliability, longevity, and environmental resistance matter, ASA is simply the correct material.

From the buyer’s side, ASA is all about value over time: • Doesn’t break down in the sun — no cracking or chalking • Looks professional even after months outside • Good for low-volume runs with no tooling needed • Strong enough to handle everyday use

So if you're replacing something that's exposed to the weather — don’t waste money on ABS or PLA. Go straight to ASA and know it’ll last.

FAQs

Is Asa suitable for outdoor use?

It depends on UV exposure and heat. Tell us the environment and we’ll advise the best material.

Can you print Asa for functional parts?

Yes. If you share the part purpose and any load/heat details, we’ll confirm the best settings and material choice.