Domestic 3D Printing Services - Household & Garden Tools

Fast, affordable 3D printed solutions for household components and appliance spares — extend product life with bespoke parts and rapid replacements.

A Sector Built on Necessity, Longevity, and Quiet Resilience

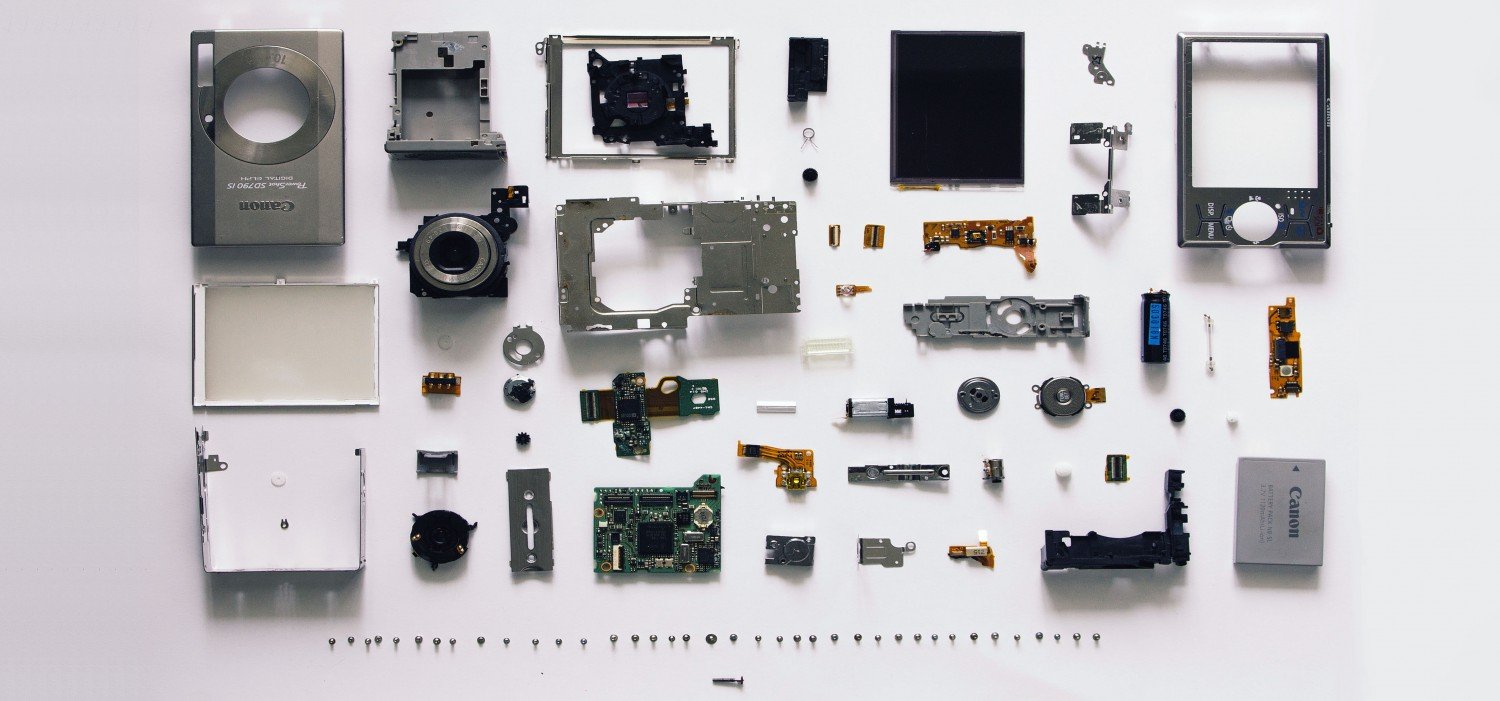

The domestic spares parts industry is not glamorous, but it is absolutely critical. It sits behind almost every home in the country, quietly keeping washing machines running, boilers safe, ovens functional, garden equipment operational, and countless everyday products alive well beyond their original warranty period. What makes this industry unique is that it exists almost entirely because of failure — not catastrophic failure, but small, irritating, disruptive failures. A cracked clip, a worn gear, a brittle housing, a snapped latch. Individually these parts are insignificant. Collectively, they represent millions of pounds in wasted appliances every year when replacements are unavailable or uneconomical. The domestic spares sector exists to fight planned obsolescence, supply-chain gaps, and the reality that manufacturers simply do not support products forever.

Historically, this industry relied heavily on centralised manufacturing, warehousing, and long-tail inventory strategies. OEMs would produce spare parts for a limited time, store them, and gradually phase them out as products aged. Once a part was no longer profitable to store or demand dropped below a threshold, it disappeared. For consumers, that meant a perfectly serviceable appliance could be rendered useless by a £2 plastic component that no longer existed. Independent spares suppliers stepped in, scavenging, refurbishing, and reverse-engineering where possible, but they were still constrained by tooling costs, minimum order quantities, and physical storage. This created a system where availability was dictated not by need, but by economics.

What truly sets the domestic spares parts industry apart is its diversity and fragmentation. There is no single standard, no universal specification, no shared design language. Every manufacturer, every model, every revision introduces slight variations. A clip from one washing machine is not quite the same as a clip from the next revision. A dishwasher bracket may change thickness by a millimetre. This constant variation makes traditional mass manufacturing inefficient for low-volume replacements. It also makes the industry highly dependent on skilled problem-solvers — people who can identify parts, measure them, understand their function, and find practical ways to reproduce them without original tooling or drawings.

This is where the industry’s resilience shows. It has always adapted. When parts could be machined, they were machined. When plastics dominated, moulding took over. When supply chains tightened, improvisation filled the gaps. Now, with the rise of additive manufacturing, the domestic spares parts industry is entering a phase where adaptability is no longer a workaround — it is the core capability. The industry is no longer limited by warehouses or tooling amortisation. It is limited only by design understanding, material selection, and production knowledge. That shift is fundamental, and it is reshaping what “spares availability” actually means.

Why Domestic Spares Are Fundamentally Different from General Manufacturing

Domestic spares parts are not products in the traditional sense; they are solutions to very specific problems. Unlike consumer goods designed for sale, spares are designed for compatibility, fit, and function within an existing system. They must work first time, often without the luxury of testing environments or iterative redesigns. A spare part does not get a second chance — if it fails, it damages trust, time, and sometimes safety. That alone places the domestic spares industry in a different category to mainstream manufacturing.

Another defining characteristic is unpredictability. Demand is not forecastable in the same way as consumer products. A particular fridge hinge may suddenly become popular because a common failure point emerges after seven years of use. A vacuum cleaner latch might fail en masse due to material ageing rather than usage. These demand spikes are impossible to plan for using traditional supply models. As a result, many spares simply never justify the cost of retooling or remanufacture, even though the demand is real and persistent.

There is also a strong emotional and practical dimension. Domestic appliances are deeply embedded in daily life. When something breaks, it disrupts routines immediately. People do not want to replace a £600 appliance because of a failed plastic tab. They want it fixed, quickly, affordably, and reliably. This creates a market that values responsiveness over scale, and precision over branding. The domestic spares industry thrives not on volume, but on trust and problem-solving.

Material performance further complicates matters. Many domestic spares are made from engineering plastics that degrade over time. UV exposure, heat cycles, moisture, vibration — all contribute to brittleness and failure. Original materials were often chosen for cost efficiency at scale, not long-term durability. When reproducing spares, there is an opportunity not just to replicate, but to improve. Selecting a more UV-stable polymer, reinforcing stress points, or adjusting wall thickness can dramatically extend a part’s lifespan without altering its function. Traditional manufacturing rarely revisits old designs; the domestic spares industry does so out of necessity.

This is precisely why 3D printing aligns so well with this sector. It is not about novelty or speed alone. It is about control — control over geometry, material, infill, strength, and iteration. It allows spares to be treated as engineered responses rather than commodity items. That distinction matters.

How 3D Printing Directly Transforms Domestic Spares Availability

The most immediate benefit of 3D printing within the domestic spares industry is the removal of tooling dependency. Injection moulding is excellent for high volumes, but it is economically irrational for low-volume or discontinued parts. Tooling costs alone can run into thousands, long before a single part is produced. For domestic spares, where demand may be tens or hundreds rather than tens of thousands, this model simply does not work. Additive manufacturing removes that barrier entirely.

With 3D printing, the cost is front-loaded into design and setup, not tooling. Once a part is modelled accurately in CAD, it can be produced on demand, repeatedly, without additional capital investment. This fundamentally changes the economics of spares. Parts that were previously “obsolete” become viable again. Rare components can be produced as needed. Stock does not need to exist physically — it exists digitally, ready to be manufactured when required.

Another critical advantage is speed. Traditional supply chains can take weeks or months to respond, assuming the part is still available at all. 3D printing collapses that timeline dramatically. A broken component can be measured, modelled, printed, and installed in days, sometimes hours. For domestic environments, this responsiveness is transformative. It reduces downtime, frustration, and unnecessary waste.

Material choice is equally important. Modern additive manufacturing materials are not limited to brittle plastics. ABS, PETG, nylon, carbon-fibre-reinforced polymers, and flexible materials all have a place within domestic spares. Each can be selected based on real-world usage rather than original cost constraints. A clip that failed due to brittleness can be reproduced in a tougher, more resilient polymer. A housing that cracked due to heat exposure can be redesigned with improved thermal resistance. This is not theoretical — it is happening now.

Perhaps most importantly, 3D printing enables reverse engineering at a practical level. Many domestic spares lack drawings, part numbers, or documentation. Physical samples become the reference. With calipers, scanners, and CAD software, functional replicas can be produced even when manufacturers have long since moved on. This capability turns the domestic spares industry into a preservation system for everyday technology — extending product lifespans in a way mass manufacturing never prioritised.

The Economic Impact: Keeping Money Local and Waste Out of Landfill

From an economic perspective, the integration of 3D printing into the domestic spares industry has profound implications. Instead of money flowing outwards to large manufacturers or overseas suppliers, value is retained locally. Small engineering firms, repair specialists, and additive manufacturing providers become central players. This decentralisation strengthens local economies and reduces dependence on fragile global supply chains.

Consumers benefit directly through reduced replacement costs. Repair becomes viable again. Appliances last longer. Households spend less replacing entire units and more maintaining what they already own. This is not just cost-saving; it is resource efficiency. The environmental benefit of extending product life far outweighs the footprint of producing a small replacement part.

For businesses, especially repair companies, 3D printing unlocks new service models. Instead of turning customers away due to unavailable parts, they can offer bespoke solutions. This increases customer loyalty, reduces churn, and positions repair as a modern, technically capable service rather than a declining trade. The domestic spares industry becomes future-proof rather than nostalgic.

There is also a broader industrial benefit. Skills development shifts from manual fabrication alone to digital design, materials science, and process control. This creates higher-value roles and encourages technical upskilling. The industry becomes more attractive to younger engineers who might otherwise overlook repair-focused sectors.

Ultimately, the domestic spares parts industry, when combined with 3D printing, becomes a quiet force against waste, obsolescence, and unnecessary consumption. It does not shout about innovation, but it delivers it where it matters most — in everyday life.

Why This Shift Is Not Optional, but Inevitable

The reality is simple: manufacturers are not going to reverse decades of planned obsolescence. Warehousing discontinued parts indefinitely is not commercially viable for them. Global supply chains will continue to experience disruption. Against that backdrop, the domestic spares industry must evolve or shrink. 3D printing is not a trend in this context; it is a structural solution.

What makes this transition particularly compelling is that it aligns incentives. Consumers want repairs. Repairers want solutions. Local manufacturers want sustainable work. Additive manufacturing provides a practical bridge between all three. It replaces scale with intelligence, volume with precision, and disposability with longevity.

In my view, the domestic spares parts industry is entering its most important phase yet. Not because of technology alone, but because the mindset is changing. Repair is no longer seen as a compromise. With the right materials, design, and production methods, repaired parts can outperform originals. That is a powerful shift — and one that will define the industry for years to come.

FAQs

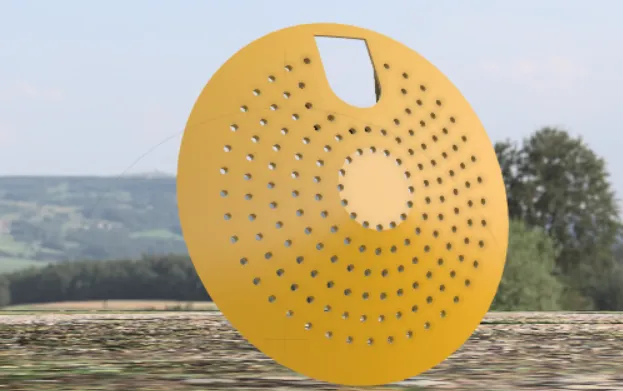

Is Domestic suitable for outdoor use?

It depends on UV exposure and heat. Tell us the environment and we’ll advise the best material.

Can you print Domestic for functional parts?

Yes. If you share the part purpose and any load/heat details, we’ll confirm the best settings and material choice.