PETG 3D Printing Material UK | Tough & Easy‑Print Polymer

PETG filament — tough, flexible and UV‑resistant 3D printing material for reliable industrial and everyday part production.

PETG – Tough, UV‑Resistant 3D Printing for Outdoor and Functional Parts

PETG is one of those materials that just ticks a lot of boxes. It’s strong, flexible, looks good straight off the printer, and holds up really well outdoors. If you’re trying to decide between ABS and something a bit more durable long-term — especially if UV exposure is a concern — I’ll often point you toward PETG.

I’ve used PETG for all sorts of jobs where ABS just wasn’t going to last. Outdoor enclosures, brackets, replacement parts for garden machinery — anywhere that sits in the sun or faces the weather. With PETG, you get strength like ABS but it won’t go brittle after a couple of years.

Key Technical Specifications (Typical Values)

• Tensile strength: 45–55 MPa • Elongation at break: 20–30% • Heat deflection temperature: 70–80°C • Impact resistance: Moderate to high • UV resistance: Very good • Chemical resistance: Good (alkalis, acids, oils) • Density: ~1.27 g/cm³ • Surface finish: Natural gloss, smooth layers

It’s a great all-rounder. Not too brittle, not too soft. And with a bit of tweaking in the print settings, it produces solid, dependable results.

PETG Filament Explained – Why This Material Exists

PETG exists because real-world engineering problems demand compromise. PLA is easy to print but softens at relatively low temperatures and degrades outdoors. ABS is strong and heat-resistant but difficult to print reliably and degrades under prolonged UV exposure. PETG was developed to bridge that gap, delivering strength, durability, and environmental resistance without turning every print into a battle against warping and failed layers.

From a material science perspective, PETG is an amorphous thermoplastic. This means it does not crystallise as it cools, which is why it remains dimensionally stable during printing. That single characteristic eliminates one of the biggest headaches in additive manufacturing: unpredictable shrinkage. As a result, PETG prints flat, holds tolerances well, and maintains consistent layer bonding across the entire part.

What makes PETG particularly attractive is its molecular toughness. Unlike PLA, which tends to fracture when overstressed, PETG will flex before it fails. This ductility is invaluable for clips, brackets, enclosures, and mechanical components that experience vibration, repeated handling, or impact. It does not shatter; it absorbs energy. That behaviour alone opens the door to a wide range of industrial and consumer applications.

Another defining trait is PETG’s chemical resistance. Oils, greases, mild acids, cleaning chemicals, and saltwater have minimal effect on PETG. This is why it is commonly used in food containers, medical packaging, and laboratory equipment. Translated into 3D printing, it means PETG components can be used in workshops, marine environments, kitchens, and healthcare settings without rapid degradation.

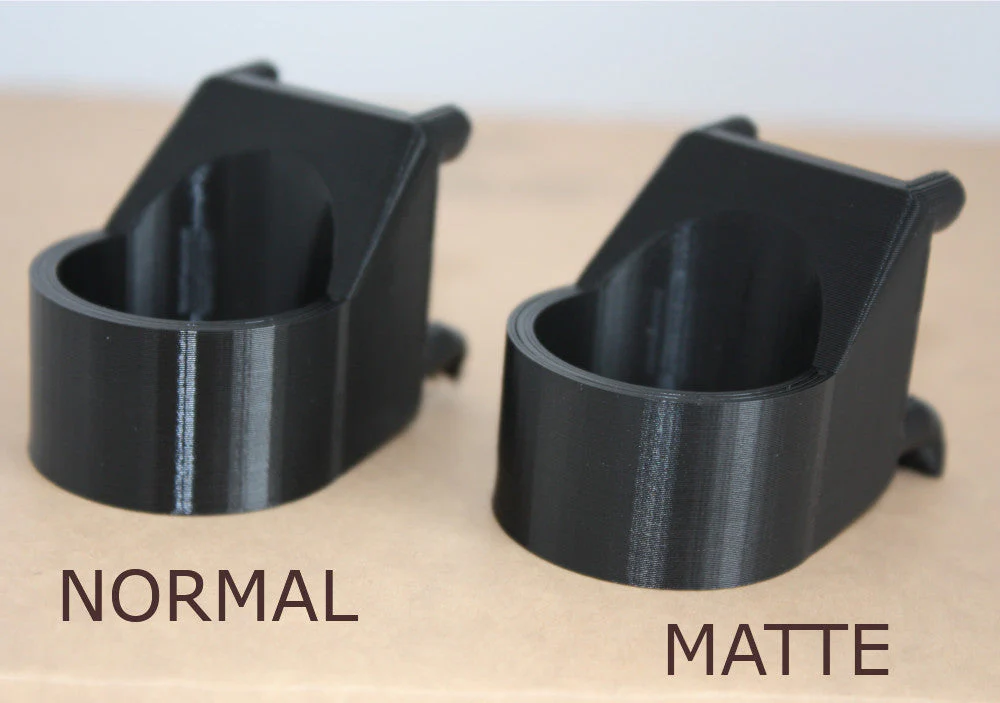

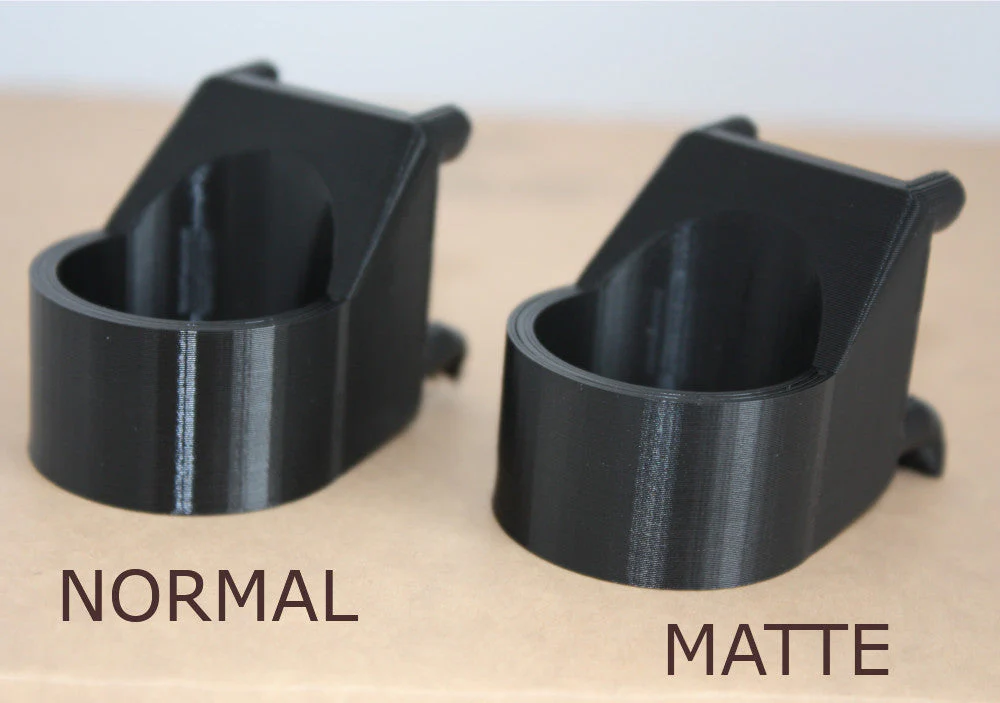

Visually, PETG offers a natural semi-gloss to gloss finish straight off the printer. This is not a cosmetic gimmick; it is a by-product of how the material flows and fuses at printing temperatures. The result is a finished part that often requires little to no post-processing for functional or professional use.

In short, PETG exists because industry needed a material that behaves predictably, lasts outdoors, and still prints reliably on standard FDM machines. It is not a compromise material—it is a deliberately engineered solution to real manufacturing limitations.

What Makes PETG Unique Compared to Other Filaments

PETG’s uniqueness lies not in a single headline feature, but in how consistently it performs across multiple dimensions. Strength, flexibility, environmental resistance, print reliability, and surface finish are all present in meaningful measure, rather than one coming at the expense of the others.

One of PETG’s standout characteristics is exceptional layer adhesion. When printed correctly, PETG layers fuse so well that the finished part often fails across the material itself rather than along layer lines. This is critical for load-bearing components and is one of the main reasons PETG outperforms PLA in functional testing despite similar tensile strength figures on paper.

Another differentiator is UV resistance. Where ABS becomes brittle after prolonged sunlight exposure and PLA softens and discolours, PETG maintains its structural integrity for years. This makes it particularly well suited to outdoor applications such as garden fixtures, external enclosures, signage mounts, and marine hardware.

PETG is also hygienic by nature. It is non-porous when printed correctly, does not readily absorb moisture, and is naturally resistant to bacterial growth. This makes it appropriate for medical accessories, food-adjacent tools, and laboratory fixtures where cleanliness matters.

From a manufacturing standpoint, PETG is forgiving. It does not require a fully enclosed printer, it tolerates minor temperature fluctuations, and it adheres well to most build surfaces without aggressive adhesives. This reliability reduces waste, lowers production costs, and increases repeatability—key considerations in professional additive manufacturing.

Crucially, PETG is recyclable and derived from one of the most widely recycled plastic families in the world. While recycling filament itself requires specialist processes, the base polymer aligns well with modern sustainability goals.

PETG’s uniqueness is therefore holistic. It does not excel in just one narrow use case; it performs consistently across many. That versatility is exactly why PETG has become a go-to material for engineers, restorers, and manufacturers who need parts that actually work, not just parts that look good.

How PETG Enables Practical, Cost-Effective 3D Printing

The true value of PETG emerges when cost, performance, and production speed are evaluated together. Traditional manufacturing methods such as injection moulding are financially impractical for low-volume or bespoke parts due to tooling costs that often exceed several thousand pounds before a single component is produced.

PETG changes that equation entirely.

With 3D printing, a PETG component can be designed, tested, refined, and produced within days rather than months. There is no tooling, no minimum order quantity, and no long supply chains. This is particularly valuable when dealing with obsolete parts, discontinued components, or niche equipment where replacements simply do not exist.

PETG’s print reliability reduces failure rates, meaning less wasted material and machine time. Its strength allows parts to be printed at higher infill densities for structural use or reduced infill for cost-effective solutions without compromising durability. That flexibility allows manufacturers to tailor the part precisely to its real-world demands.

Because PETG does not require extreme printing conditions, energy consumption is lower than high-temperature engineering plastics. This further reduces operating costs while maintaining performance.

For businesses, this means rapid problem-solving. For individuals, it means access to durable, professional-grade components without industrial overheads. PETG is not just a material—it is an enabler of decentralised, agile manufacturing.

Technical Properties of PETG Filament

PETG’s performance is grounded in measurable engineering data:

Tensile Strength: 45–55 MPa

Elongation at Break: 20–25%

Flexural Strength: ~70 MPa

Impact Resistance: High (significantly higher than PLA)

Glass Transition Temperature (Tg): ~80°C

Melting Temperature: ~230–260°C

Density: ~1.27 g/cm³

Water Absorption: Low

Chemical Resistance: Excellent against oils, salts, and mild acids

These figures explain PETG’s real-world behaviour. It withstands mechanical stress, tolerates moderate heat, and resists environmental degradation without becoming brittle. For many applications, PETG offers more than enough performance margin while remaining easy to manufacture.

Real-World Application: Restoring and Replacing Functional Components

A practical example of PETG’s value can be found in restoration work. When original plastic components are no longer available, PETG allows those parts to be reverse-engineered, redesigned, and reproduced with improved longevity.

Consider control clips, housings, brackets, or levers exposed to sunlight, vibration, and handling. Where ABS would degrade over time and PLA would fail prematurely, PETG maintains strength and appearance. By printing with high infill and appropriate wall thickness, the resulting component can outperform the original injection-moulded part.

The financial impact is significant. Instead of paying thousands for tooling or sourcing obsolete stock, a PETG component can be produced for a fraction of the cost, often within days. That is not theoretical—it is happening daily across transport, manufacturing, marine, and heritage sectors.

FAQs

Is Petg suitable for outdoor use?

It depends on UV exposure and heat. Tell us the environment and we’ll advise the best material.

Can you print Petg for functional parts?

Yes. If you share the part purpose and any load/heat details, we’ll confirm the best settings and material choice.