Carbon Fibre PLA 3D Filament UK | Stiffer, Lightweight Parts

Carbon fibre reinforced PLA for stiffer 3D prints with improved rigidity — great for visual prototypes and lightweight components.

PLA‑CF – Rigid, Lightweight and Cleaner Prints with Extra Strength

PLA‑CF is exactly what it sounds like — standard PLA, but reinforced with carbon fibre particles. What does that do? It stiffens the print, reduces warping, and makes your parts a lot more dimensionally stable. You lose a bit of flexibility compared to normal PLA, but what you get back is a part that feels much more like a production-grade plastic.

We use it when customers need something that looks good, stays flat, and doesn’t feel like it’ll snap if you sneeze on it. Perfect for enclosures, brackets, tooling fixtures, or high-quality visual models with a bit more backbone.

Key Technical Specifications (Typical Values)

• Tensile strength: 60–75 MPa • Elongation at break: 1.5–3% • Heat deflection temperature: ~65°C • Density: ~1.3 g/cm³ • Surface finish: Matte, carbon-like texture • Rigidity: High – low flex, solid feel • UV resistance: Poor – not for outdoor use • Abrasion resistance: Better than PLA – thanks to carbon content

This material gives you a solid part straight off the bed — no warping, no messing about, just clean, strong results.

What Makes PLA-CF Unique Compared to Standard PLA

What makes PLA-CF genuinely unique is not just that carbon fibre is added, but how that addition alters the behaviour of the filament across the entire printing process and final part performance. Standard PLA is relatively isotropic in feel but mechanically limited; it bends before it breaks, creeps under sustained load, and can deform slightly in warm environments. PLA-CF, by contrast, trades a small amount of ductility for a significant increase in rigidity and dimensional stability.

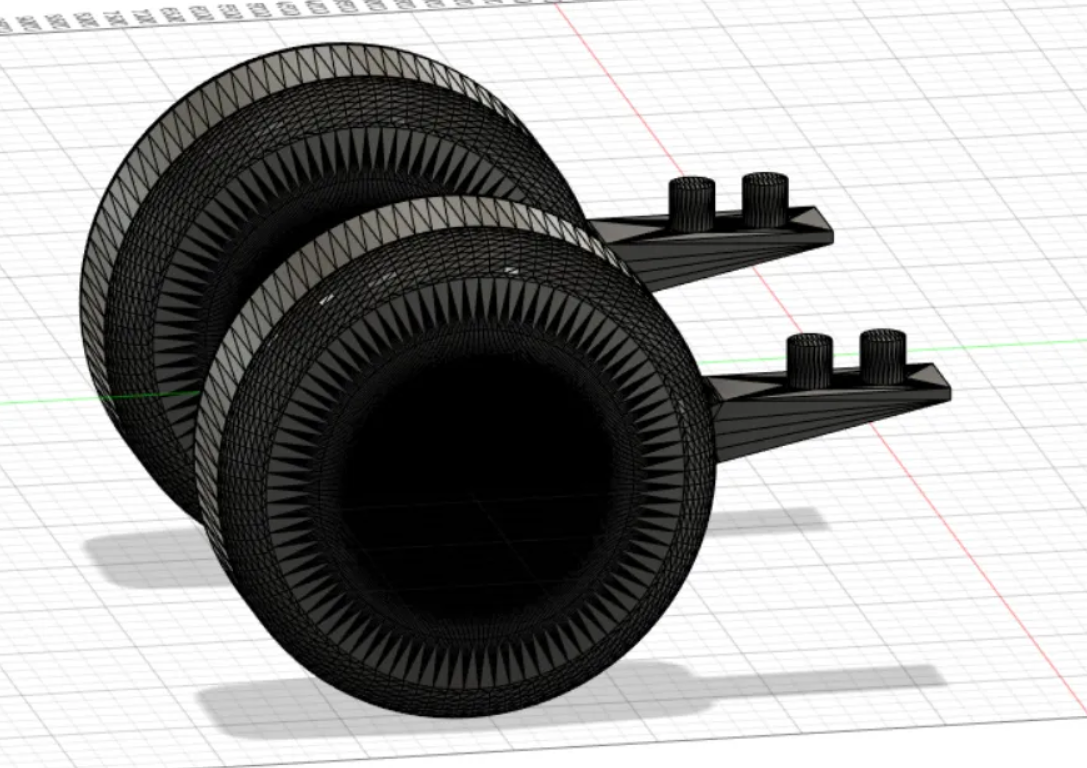

The carbon fibres embedded in the PLA matrix restrict polymer chain movement. That means once a PLA-CF part is printed, it tends to stay exactly where you put it. Holes remain round, flat faces remain flat, and long spans resist sagging far better than standard PLA. This is why PLA-CF is often used for calibration tools, alignment jigs, camera mounts, and mechanical housings where accuracy actually matters.

Another defining characteristic is surface finish. PLA-CF naturally prints with a matte, almost satin-black appearance. Layer lines are visually muted, and reflections are reduced. In many industrial and professional settings, this alone is enough to choose PLA-CF over glossy plastics. A part that looks “engineered” rather than “printed” changes how it is perceived by customers, inspectors, and stakeholders.

From a thermal perspective, PLA-CF performs slightly better than regular PLA. While the glass transition temperature remains in the same general region (around 55–60 °C), the carbon fibres reduce deformation under moderate heat loads. This does not make it a high-temperature material, but it does make it more predictable in warm workshops, inside enclosures, or near electronics.

There are trade-offs, and it is important to be honest about them. PLA-CF is more brittle than standard PLA. It does not like sharp impacts or flexing. You design for stiffness, not for snap-fit hinges or living joints. It is also abrasive. The carbon fibres will destroy a brass nozzle quickly, which is why a hardened steel or ruby nozzle is non-negotiable.

In short, PLA-CF is unique because it turns PLA from a general-purpose plastic into a precision material. When accuracy, rigidity, and professional appearance matter more than flexibility or impact resistance, PLA-CF is often the correct answer.

Why PLA-CF Exists and Where It Fits in 3D Printing

PLA-CF exists because real-world users needed something better than standard PLA, but simpler than high-end engineering plastics. Not every project justifies Nylon-CF, ASA, or polycarbonates. Those materials require enclosed printers, moisture control, higher temperatures, and longer setup times. PLA-CF fills that gap by offering engineering-style stiffness with PLA-level ease of use.

From a workflow perspective, this matters enormously. In production environments, time is money. Being able to print a rigid, dimensionally accurate part without fighting warping, layer separation, or moisture absorption makes PLA-CF attractive for fast-turnaround jobs. That is why you see it used heavily in manufacturing support tooling: drill guides, assembly fixtures, inspection jigs, sensor mounts, and machine guards.

PLA-CF also shines in low-volume production. Injection moulding simply does not make sense when you need ten parts, not ten thousand. Tooling costs alone can reach £5,000–£10,000 before a single component exists. With PLA-CF, you can design, print, test, revise, and deploy functional components within days, sometimes hours. That agility is one of the biggest economic advantages of additive manufacturing.

Another reason PLA-CF exists is dimensional confidence. Carbon fibre reduces shrinkage and thermal distortion during cooling. That means tighter tolerances straight off the printer. For applications like camera rigs, mounting plates, enclosures, and alignment components, this reliability removes a huge amount of post-processing work.

Importantly, PLA-CF encourages better design thinking. Because it does not tolerate flex, it pushes designers to use ribs, gussets, fillets, and proper load paths. In many ways, it teaches people to design like engineers rather than artists. That alone improves product quality across the board.

PLA-CF is not a replacement for every material. It sits comfortably between PLA and Nylon-CF, offering a pragmatic balance. When customers ask me why it exists, the answer is simple: it solves real problems without introducing new ones.

How 3D Printing with PLA-CF Delivers Real Benefits

The real benefit of 3D printing with PLA-CF is not theoretical performance; it is problem-solving speed. When a machine is down, a bracket has failed, or a component is obsolete, waiting weeks for a replacement is often unacceptable. With PLA-CF, you can reverse-engineer, redesign, and manufacture a functional replacement rapidly.

From a mechanical standpoint, PLA-CF parts perform exceptionally well in compression and static load scenarios. Mounts, housings, brackets, and frames benefit from its rigidity. Unlike flexible plastics, PLA-CF does not “give” under load, which is exactly what you want in positioning components or alignment systems.

There is also a cost benefit that is often overlooked. While PLA-CF is more expensive per kilogram than standard PLA, the overall project cost is often lower. You get better performance per print, fewer failed parts, less post-processing, and fewer redesigns. That adds up quickly in professional environments.

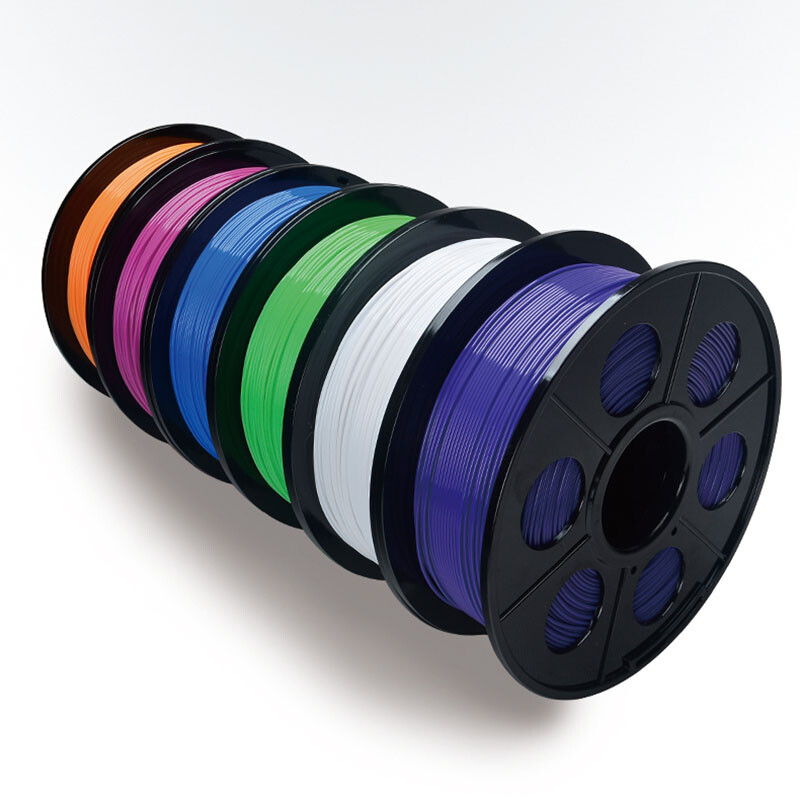

Another benefit is print reliability. PLA-CF typically prints at 200–230 °C with minimal warping and no enclosure requirement. Bed adhesion is strong, and layer consistency is excellent. That means fewer surprises, which matters when you are delivering parts to paying customers.

PLA-CF also reduces visual noise. Parts look intentional. That matters more than people realise. A matte black, carbon-filled part looks like something that belongs on machinery, not a prototype cobbled together in a garage.

Technical Performance and Material Properties

From a technical standpoint, PLA-CF offers a compelling set of properties:

Tensile strength: typically 45–60 MPa

Elastic modulus: significantly higher than PLA (often 5–7 GPa)

Elongation at break: low, usually 2–5%

Density: ~1.2–1.3 g/cm³

Glass transition temperature: ~55–60 °C

Recommended nozzle: hardened steel or ruby

Layer adhesion: good, but not flexible

The increased modulus is the key figure here. It is what gives PLA-CF its stiffness and dimensional stability. However, the low elongation means impact resistance is reduced. This is not a material for snap-fits or living hinges.

Print settings matter. Lower layer heights improve surface finish and strength consistency. Infill patterns should favour structural rigidity, and wall thickness should be increased compared to PLA. In most cases, 3–4 perimeters and 30–50% infill deliver excellent results without unnecessary material usage.

Real-World Application Example

A real-world example where PLA-CF excels is industrial sensor mounting. Sensors must be held rigidly, aligned accurately, and remain stable over time. Standard PLA can creep, and flexible plastics introduce vibration. Aluminium is expensive and slow to machine for one-off parts.

Using PLA-CF, a sensor mount can be designed in CAD, printed within hours, and installed the same day. The rigidity ensures alignment stays true, while the matte finish reduces glare and visual interference. If adjustments are required, the design can be revised and reprinted without scrapping tooling.

This is where PLA-CF truly earns its place: fast, precise, functional manufacturing without unnecessary complexity.

FAQs

Is Pla Cf suitable for outdoor use?

It depends on UV exposure and heat. Tell us the environment and we’ll advise the best material.

Can you print Pla Cf for functional parts?

Yes. If you share the part purpose and any load/heat details, we’ll confirm the best settings and material choice.