Automotive 3D Printing - Obsolete Car & Vehicle Spare Parts

3D printing and reverse engineering for automotive spares and legacy vehicle parts — produce functional components on demand without tooling costs and long lead times

The Automotive Spare Parts Industry: A Sector Under Constant Pressure

The Automotive Spare Parts Industry: A Sector Under Constant Pressure

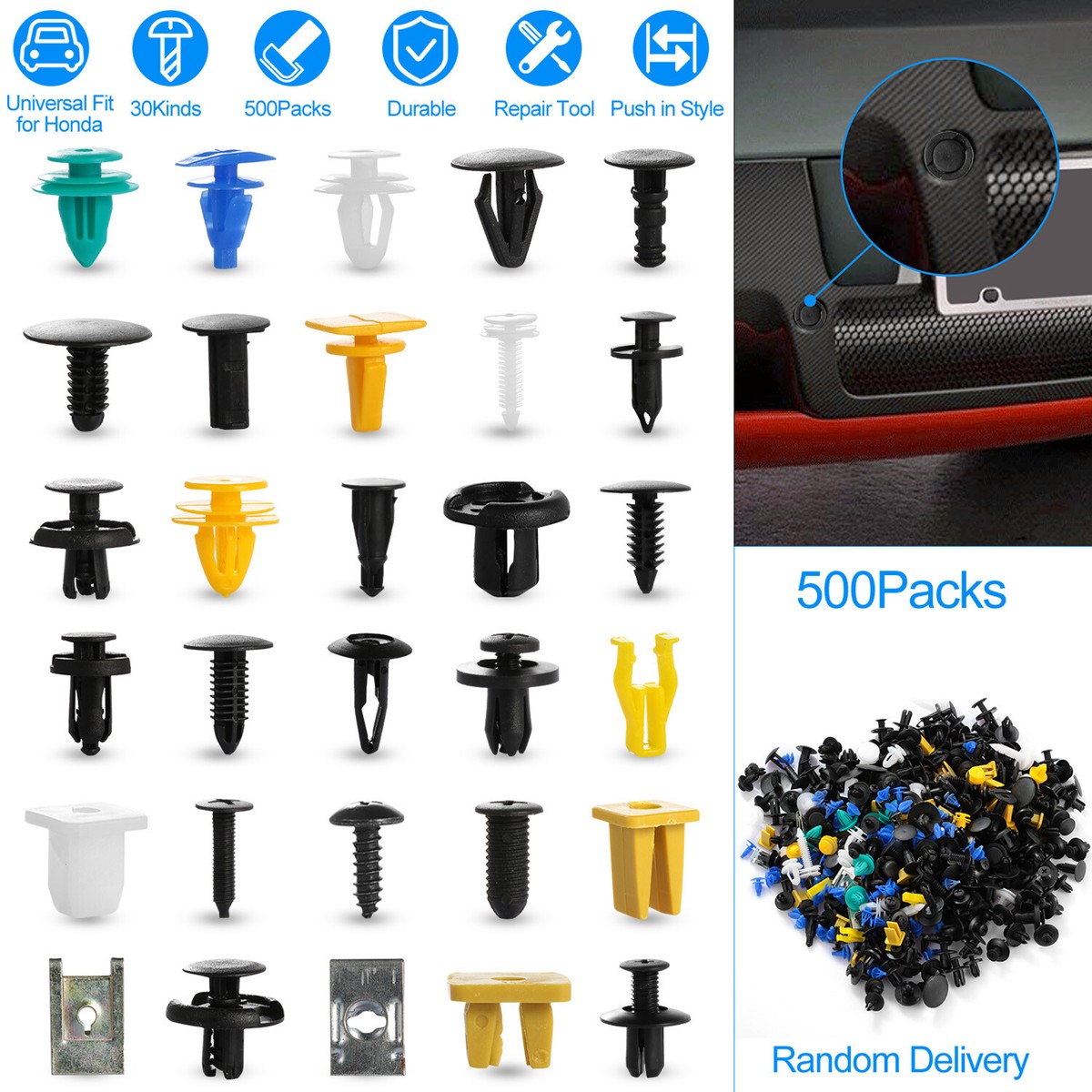

The automotive spare parts industry sits in a permanently reactive state. Vehicles are expected to last longer than ever, yet manufacturers are under relentless pressure to cut costs, reduce inventory, and move on to newer platforms as quickly as possible. This creates a widening gap between what vehicle owners, restorers, fleet operators, and maintenance teams actually need, and what the traditional supply chain can realistically provide. Obsolete parts, discontinued moulds, minimum order quantities, and long lead times are not rare exceptions – they are the norm. From plastic clips and trim components to brackets, housings, and functional fixtures, countless parts fail not because they are complex, but because they are no longer commercially viable to manufacture at scale. This is where the industry begins to show its cracks. Injection moulding, while excellent for high-volume production, is completely uneconomical for low-volume or one-off spares. Tooling costs alone can run into thousands before a single part exists, and that assumes the original tooling even still exists. In practice, it often does not. This structural inefficiency is precisely why the spare parts sector is ripe for disruption. Not through gimmicks or shortcuts, but through a fundamentally different way of thinking about manufacturing: producing parts when and where they are needed, in the quantities required, without the overheads of traditional tooling.

What Makes the Automotive Spare Parts Industry Unique

What truly sets the automotive spare parts industry apart is the sheer diversity of demand. Unlike mass vehicle production, spares are fragmented, unpredictable, and time-sensitive. A single missing clip can immobilise a £40,000 vehicle. A broken bracket can ground an entire fleet. Restoration projects rely on components that may not have been manufactured for decades. This industry is not about millions of identical units; it is about precision, compatibility, and reliability across thousands of variations. The tolerances matter. The materials matter. The usage environment matters. Heat, vibration, UV exposure, oils, fuels, and constant mechanical stress all come into play. This is why “close enough” is not good enough. Automotive spares must function as intended, often under harsher conditions than when the vehicle was new. The uniqueness lies in the fact that failure is rarely acceptable, yet traditional manufacturing methods are poorly suited to serve this long-tail demand. Warehousing every possible spare is financially impossible. Re-tooling for every obsolete component makes no commercial sense. As a result, the industry has historically relied on compromise: used parts, substandard alternatives, or workarounds. That compromise costs time, money, and reliability.

Why Traditional Manufacturing Falls Short

Injection moulding and CNC machining dominate automotive manufacturing for good reason: they excel at scale and repeatability. However, spare parts exist at the opposite end of that spectrum. Tooling costs, setup time, and batch requirements make traditional methods slow and expensive for low-volume production. Even when parts are simple, the economics are brutal. A plastic clip that costs pennies to produce in volume can cost thousands to reintroduce once tooling is gone. Add global supply chains, shipping delays, and minimum order quantities, and the situation worsens. For older vehicles, niche models, or specialist applications, the part simply disappears from the market. This is not a technical failure; it is a commercial one. The industry has been built around volume, not longevity. As vehicles become more complex and model cycles shorten, this problem accelerates. The result is a growing aftermarket gap that traditional manufacturing cannot economically fill.

How 3D Printing Changes the Equation

3D printing fundamentally rewrites the economics of automotive spare parts. It removes tooling entirely. It allows parts to be produced directly from a digital model, on demand, in the exact quantity required. One part or one hundred parts follow the same workflow. This is not a minor efficiency gain; it is a structural shift. Reverse engineering becomes practical. A broken component can be measured, redesigned in CAD, improved where necessary, and reproduced without waiting months or spending thousands. Materials can be selected based on real-world use, not just manufacturing convenience. ABS for strength, PETG for UV resistance, nylons for wear, reinforced composites for demanding applications. Infill density can be adjusted to balance strength and cost, rather than being locked into a single moulded outcome. This flexibility is where additive manufacturing truly shines. It is not about replacing mass production; it is about complementing it where it fails.

The Real-World Benefits for the Automotive Sector

For the automotive spare parts industry, the benefits of 3D printing are immediate and tangible. Downtime is reduced because parts can be produced locally and quickly. Inventory costs drop because digital files replace physical stock. Obsolete components become viable again. Custom or improved designs can be implemented without retooling. Even strength and durability can be enhanced by redesigning internal structures rather than simply copying the original part. This is particularly valuable in applications where original components were under-engineered or prone to failure. The ability to iterate, test, and refine without prohibitive cost is transformative. It shifts the industry from reactive problem-solving to proactive improvement.

FAQs

Is Automotive suitable for outdoor use?

It depends on UV exposure and heat. Tell us the environment and we’ll advise the best material.

Can you print Automotive for functional parts?

Yes. If you share the part purpose and any load/heat details, we’ll confirm the best settings and material choice.