TPU Flexible 3D Printing Material UK | Elastic & Durable Prints

TPU flexible filament for elastic, impact‑absorbing 3D printed parts — perfect for gaskets, seals and wearable components

TPU – Flexible, Tough and Built to Take a Beating

.jpg)

TPU is your go-to material when you need a part that won’t snap, crack or shatter. I’m talking about something that bends, stretches, and still returns to shape. Think rubber‑like feel, but with more durability and better precision when printed right.

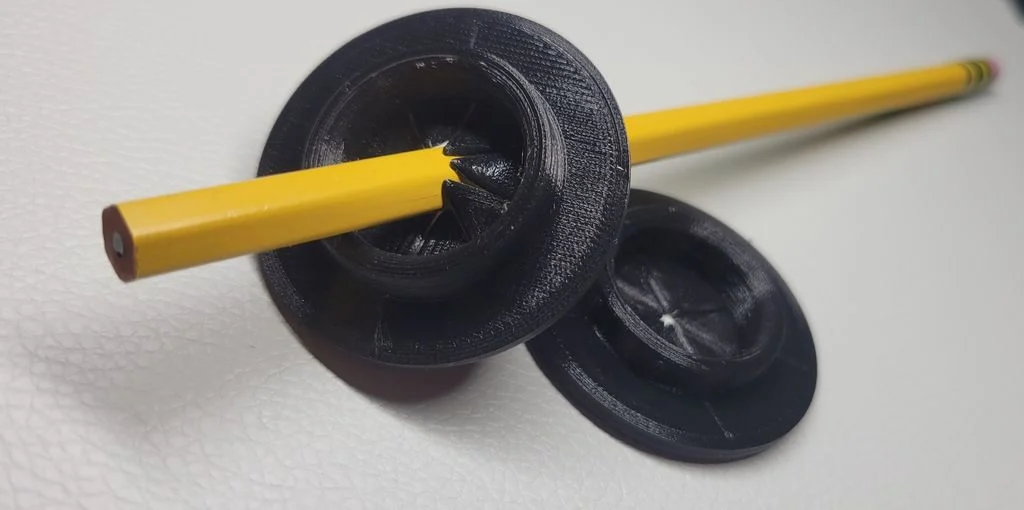

We use TPU when a customer says, “I need this to flex but still last.” Whether it’s for seals, gaskets, vibration‑dampening mounts, or custom grips — TPU is brilliant for jobs where impact resistance and flexibility are key.

Key Technical Specifications (Typical Values)

• Shore hardness: 85–95A (softer to firmer rubber feel) • Elongation at break: 300–600% • Tensile strength: 25–50 MPa • Impact resistance: Extremely high • Heat deflection temperature: 60–80°C • Density: ~1.2 g/cm³ • Abrasion resistance: Very good • UV resistance: Moderate • Chemical resistance: Good (oils, greases, some solvents)

This stuff’s built to move. You can twist it, stretch it, squash it — and it’ll still do its job.

Why Engineers Use TPU

You use TPU when something needs to absorb shock, flex under pressure, or make a seal. I recommend TPU when: • You need flexibility and repeated movement • You want to replace a rubber part without tooling • You’re prototyping parts that will later be cast in rubber • You need some impact protection in your design

It’s especially good for grommets, cable protectors, bump stops, and even shoe soles.

Real-World Applications

We’ve printed TPU parts for: • Dust seals and custom gaskets • Vibration‑dampening feet for machines • Flexible tool grips and ergonomic covers • Snap-fit connectors that need to flex • Custom bumpers for impact zones • Protective sleeves and cable guides

If it's got to flex without failing — TPU’s your best bet.

What Does 3D Printed TPU Mean?

When we talk about 3D Printed TPU, we are referring to parts manufactured using Thermoplastic Polyurethane (TPU) as the filament material in an additive manufacturing process—most commonly FDM (Fused Deposition Modelling). TPU sits in a unique space between rigid engineering plastics and rubber. It is flexible, elastic, impact-resistant, abrasion-resistant, and capable of returning to its original shape after deformation. In simple terms, it behaves like industrial-grade rubber, but it is processed like a plastic.

What makes TPU especially valuable in 3D printing is that it allows engineers, manufacturers, and repair specialists to produce flexible, durable components without tooling, without moulds, and without committing to mass production. That combination alone is a game-changer. TPU can be printed into seals, gaskets, bumpers, vibration isolators, clips, protective covers, hoses, cable strain reliefs, and countless bespoke components that previously required injection moulding or machining from rubber blocks—both expensive and time-consuming processes.

From a practical standpoint, TPU gives you elasticity, toughness, chemical resistance, and fatigue resistance in one material. It can flex thousands of times without cracking, it absorbs impact instead of shattering, and it performs reliably across a wide temperature range. That is why TPU is increasingly used in automotive interiors, marine environments, industrial machinery, medical devices, and consumer products where flexibility is not optional—it is essential.

Why This Material Is Genuinely Different

TPU is not just “flexible plastic.” That description undersells what it actually does. TPU is an elastomeric polymer with a segmented molecular structure. One part of the polymer provides elasticity, while another provides strength and stability. This dual-phase structure is what allows TPU to stretch, compress, twist, and rebound without permanent deformation.

In a real-world engineering context, this means TPU can replace rubber in many applications while offering better durability, tighter tolerances, and easier customisation. Traditional rubber parts are almost always injection moulded, which means high upfront tooling costs. With TPU, you can digitally design a component, print it, test it, adjust it, and reprint it—all within days rather than months.

Another key distinction is layer bonding. When printed correctly, TPU exhibits excellent inter-layer adhesion. Unlike brittle plastics that can delaminate under stress, TPU parts tend to fail gradually rather than catastrophically. That failure behaviour matters in safety-critical or mechanically active parts. Instead of snapping without warning, TPU stretches, deforms, and absorbs energy.

From my perspective, this is one of the reasons TPU is so valuable in repair, restoration, and industrial maintenance. When something needs to flex, survive vibration, and keep working day after day, TPU is often the most sensible choice.

Mechanical and Technical Properties of 3D Printed TPU

To understand where TPU excels, you need to look at the numbers. While exact figures vary by brand and formulation, the following ranges are typical for high-quality TPU filament used in industrial 3D printing:

Shore Hardness: Commonly Shore A 85–98

Tensile Strength: 25–55 MPa

Elongation at Break: 300–600%

Abrasion Resistance: Excellent

Impact Resistance: Very high

Operating Temperature: Approx. -30°C to +80°C (short-term higher)

Chemical Resistance: Good resistance to oils, greases, fuels, and many solvents

UV Resistance: Moderate (improved with additives or coatings)

These figures explain why TPU is used where repeated movement, vibration, or impact is involved. A rigid plastic might crack after a few cycles. TPU will simply flex and carry on doing its job.

Print parameters matter a great deal with TPU. Slower print speeds, controlled extrusion, and proper filament drying are critical. When printed correctly, TPU parts are not “soft toys”—they are industrial components capable of long service lives.

How 3D Printing with TPU Actually Works in Practice

TPU (Thermoplastic Polyurethane) is a flexible 3D printing filament known for its elasticity, durability, and resistance to abrasion. Here is some technical data on 3D Printed TPU filament:

Melting Temperature: The melting temperature for TPU filament is typically around 220-240°C. It is important to maintain a consistent temperature throughout the printing process to ensure quality prints.

Filament Diameter: The diameter of TPU filament is usually 1.75mm or 3mm, but it can vary depending on the manufacturer.

Print Bed Temperature: The recommended print bed temperature for TPU filament is around 50-60°C. This is not always necessary, but it can help with adhesion to the print bed.

Cooling: TPU filament requires some cooling during the printing process to prevent warping and improve dimensional stability.

Tensile Strength: TPU filament has a relatively low tensile strength of around 20-25 MPa, but it has high elongation at break, which means it can stretch without breaking.

Printing TPU is very different from printing PLA or ABS. TPU is elastic even before it melts, which means it behaves more like a spring than a rigid rod as it feeds through the extruder. This requires controlled filament paths, direct-drive extruders, and well-tuned retraction settings.

From a manufacturing standpoint, this is not a disadvantage—it is simply part of the process. Once dialled in, TPU printing is extremely repeatable. Wall thickness, infill density, and print orientation allow fine control over flexibility. A solid TPU part can be surprisingly firm, while a low-infill TPU component can behave almost like foam rubber.

This adjustability is where TPU truly shines. You are not locked into a single stiffness or behaviour. By altering design geometry and print parameters, you can tune a component to behave exactly as required. That level of control is simply not possible with off-the-shelf rubber components.

FAQs

Is Tpu suitable for outdoor use?

It depends on UV exposure and heat. Tell us the environment and we’ll advise the best material.

Can you print Tpu for functional parts?

Yes. If you share the part purpose and any load/heat details, we’ll confirm the best settings and material choice.