None Critical Spare Parts for the Defence Industry

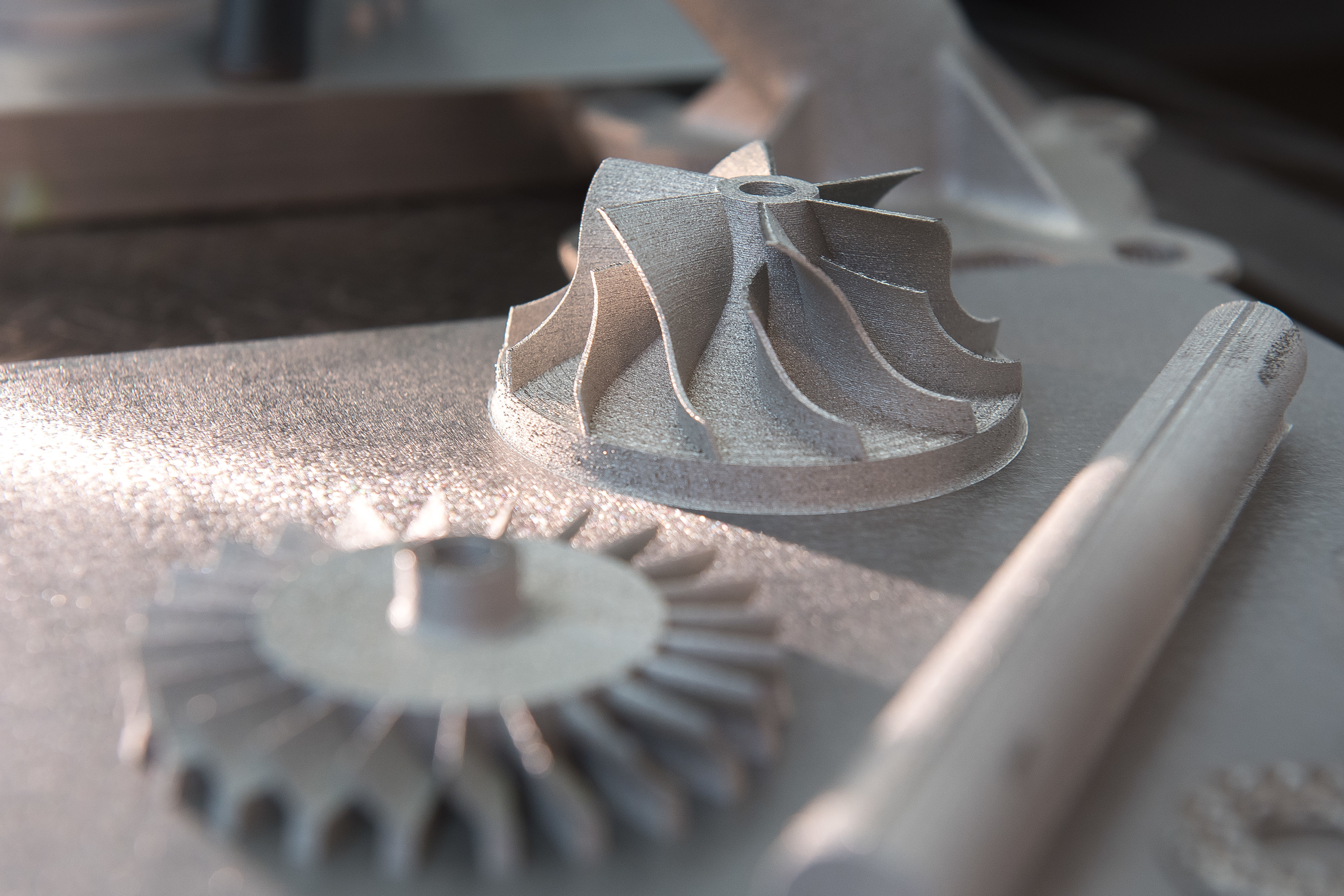

3D Printed Defence parts, is a practical choice when you need the right balance of performance, finish, and cost for functional parts.

None-Critical Spare Parts in the Defence Industry: Why They Matter More Than Most Realise

When people think about the defence industry, their minds usually go straight to complex weapons systems, advanced avionics, or heavily classified technologies. What is far less visible—but equally important—are none-critical spare parts. These are the components that do not directly affect weapons performance, safety-critical flight systems, or classified combat capabilities, yet without them, vehicles, equipment, and infrastructure quickly become unusable. Clips, housings, covers, brackets, cable guides, protective shrouds, mounting plates, seals, fixtures, knobs, and enclosures rarely make headlines, but they are everywhere. If one fails or goes missing, a vehicle can be grounded, a system taken offline, or a piece of equipment sidelined for weeks while procurement works through slow supply chains.

What makes none-critical spare parts unique in the defence sector is the contradiction they sit within. On one hand, they are low-value, relatively simple items. On the other, they are embedded within highly regulated, security-conscious environments. Traditional defence procurement processes were never designed to efficiently handle low-volume, legacy, or obsolete parts. Many platforms remain in service for decades—far beyond the commercial lifespan of the original suppliers. Tooling is scrapped, drawings are lost, vendors disappear, and suddenly a £5 plastic clip becomes the single point of failure for a £5 million asset.

This is where the inefficiency becomes glaring. Defence organisations often end up over-ordering spares “just in case,” tying up capital in warehouses filled with ageing stock that may never be used. Alternatively, they are forced into expensive one-off manufacturing runs through conventional machining or injection moulding, where tooling costs dwarf the value of the part itself. In some cases, equipment is cannibalised purely to keep another system operational. None of this is efficient, and none of it reflects modern manufacturing capability.

What is also unique is accountability. Even for none-critical parts, traceability, repeatability, and documentation still matter. The defence industry cannot simply order cheap replacements from unknown sources. Materials, tolerances, and fit all have to be right. That is why the opportunity for controlled, in-house or locally managed additive manufacturing is so compelling. It introduces flexibility without sacrificing oversight.

In my view, none-critical spare parts represent one of the most practical, low-risk entry points for defence organisations to adopt 3D printing at scale. They avoid the certification burden of safety-critical components while delivering immediate operational benefit. More importantly, they solve a real problem that maintenance teams deal with every single day. This is not about futuristic concepts or experimental technology—it is about keeping equipment running, costs down, and availability up, using tools that already exist and are proven.

Why Traditional Supply Chains Fail None-Critical Defence Spares

The traditional defence supply chain is optimised for large contracts, predictable demand, and long production runs. None-critical spare parts fit none of those criteria. Demand is irregular, volumes are low, and the parts themselves often relate to ageing platforms that were never designed with modern logistics in mind. The result is a system that is structurally inefficient when dealing with small, simple components.

One of the biggest issues is lead time. A broken bracket or housing may require a formal request, supplier identification, quotation, contract approval, manufacturing slot allocation, and delivery. Each step introduces delay. In commercial settings, this might be inconvenient. In defence maintenance, it can mean weeks of downtime for vehicles or equipment that are otherwise fully operational. When availability is measured in readiness levels, that delay has real consequences.

Cost is the second failure point. Low-volume manufacturing through conventional means is expensive. Injection moulding is completely uneconomical unless parts are produced in the thousands. CNC machining is precise, but time-intensive and costly for simple polymer components. Defence procurement then adds layers of compliance, audits, and documentation, pushing costs even higher. It is not unusual for a simple plastic or composite part to cost hundreds—or even thousands—of pounds by the time it reaches the end user.

Obsolescence is the third, and often most frustrating, challenge. Defence platforms are designed to last decades, but their supply chains are not. Suppliers go out of business. Materials are discontinued. CAD data is missing or locked behind legacy systems. In some cases, the only remaining example of a part is the broken one sitting on a workshop bench. Traditional manufacturing struggles here because it assumes the existence of drawings, tooling, and established production processes.

From my perspective, the most damaging aspect of this failure is the waste it creates. Perfectly serviceable equipment is taken out of use for want of a trivial component. Maintenance teams resort to workarounds that are unofficial, undocumented, and often sub-optimal. Knowledge becomes tribal rather than institutional. This is not how a modern, resilient defence operation should function.

3D printing does not replace the entire supply chain, but it does bypass its weakest points. By removing the need for tooling, minimum order quantities, and long production runs, additive manufacturing directly addresses the structural mismatch between none-critical spares and traditional procurement. That is why its impact in this specific area is so pronounced.

How 3D Printing Changes the Economics of Defence Spares

The economic shift introduced by 3D printing is fundamental, particularly for none-critical spare parts. Traditional manufacturing economics reward scale; additive manufacturing rewards precision, flexibility, and speed. For defence organisations managing thousands of low-volume parts, that difference is transformative.

With 3D printing, the cost of producing one part is not radically different from producing ten. There is no tooling amortisation, no minimum batch size, and no setup cost that dwarfs the part itself. This means spares can be produced on demand rather than forecast years in advance. Warehousing costs fall. Obsolescence risk drops. Capital is no longer tied up in shelves of “just in case” inventory.

Another economic advantage is digital inventory. Instead of storing physical parts, defence organisations can store validated CAD files. When a part is required, it is printed locally or regionally using approved materials and processes. This dramatically reduces logistics costs and dependency on fragile supply chains. In operational terms, it also means faster turnaround—hours or days instead of weeks.

Labour efficiency improves as well. Maintenance teams spend less time waiting for parts and more time maintaining equipment. Engineering teams can iterate designs quickly, improving durability or ease of installation without restarting an entire manufacturing process. Small design improvements that would never justify retooling suddenly become viable.

In my opinion, the real economic value is not just cost reduction—it is availability. Equipment that is available more often delivers better return on investment, regardless of how much it originally cost. None-critical spares may be inexpensive individually, but their absence is disproportionately costly. 3D printing directly addresses that imbalance.

Materials and Performance: Why “None-Critical” Does Not Mean “Low Quality”

Defence engineering is often defined by constraints—tight tolerances, limited documentation, ageing platforms, and urgent timelines. Mitchell & Son Additive Manufacturing exists to operate effectively within those constraints, using additive manufacturing as a practical tool rather than a theoretical solution.

Our defence work commonly begins with a problem: a broken component, an unavailable spare, or a design that no longer suits modern operational demands. Rather than forcing a one-size-fits-all manufacturing route, we assess how the part is used, what forces it is subjected to, and the environment it operates in. This informs every decision that follows, from CAD design through to material selection and print configuration.

There is a misconception that 3D-printed parts are inherently weaker or inferior. In reality, material choice and print parameters determine performance, not the manufacturing method itself. For none-critical defence spares, modern engineering polymers are more than capable of meeting functional requirements.

Materials such as ABS, PETG, nylon, and fibre-reinforced composites offer excellent durability, impact resistance, and thermal stability. By adjusting infill density, wall thickness, and print orientation, parts can be tailored precisely to their intended use. A protective cover does not need the same properties as a load-bearing bracket, and additive manufacturing allows that distinction to be made economically.

Post-processing further enhances performance. Parts can be annealed, coated, reinforced, or sealed depending on environmental exposure. This is particularly important in defence environments where temperature variation, vibration, moisture, and UV exposure are common. The idea that 3D printing is only suitable for prototypes is outdated and, frankly, incorrect.

From a quality standpoint, consistency is achieved through controlled processes rather than mass production. Once a part is validated, it can be reproduced identically whenever required. That level of repeatability is exactly what defence maintenance demands.

Risk Reduction and Security Benefits

None-critical does not mean non-sensitive. Supply chain security remains a concern, even for simple parts. 3D printing enables controlled production within secure environments, reducing exposure to counterfeit components or unvetted suppliers.

Digital control also improves traceability. Every part can be linked to a file, material batch, and production record. This aligns well with defence documentation requirements and reduces reliance on external vendors whose processes may not be fully visible.

In my view, decentralised but controlled additive manufacturing is one of the most effective ways to build resilience into defence logistics without compromising security.

FAQs

Is Defence suitable for outdoor use?

It depends on UV exposure and heat. Tell us the environment and we’ll advise the best material.

Can you print Defence for functional parts?

Yes. If you share the part purpose and any load/heat details, we’ll confirm the best settings and material choice.