Architectural 3D Printing UK - Custom Models & Functional Parts

Professional 3D printing for architectural models, bespoke components and design pieces in the UK — quality results for functional and visual applications.

Architecture in the Modern Age: What Makes It Unique Today

Architecture has always been a reflection of capability. What societies can build is dictated by the tools, materials, and thinking available at the time. What makes architecture unique today is not simply how buildings look, but how they are conceived, tested, refined, and delivered. We are no longer bound to straight lines because they are easier to draw, nor to uniform components because they are cheaper to manufacture. Architecture has entered a phase where complexity is no longer the enemy of affordability; in many cases, it is the very thing that unlocks efficiency.

Historically, architectural ambition was constrained by repetition. Bricks, blocks, beams, and panels all thrive on standardisation. That approach worked well for speed and scale, but it limited creativity and often forced designers to compromise between form and function. Today, digital design has removed that limitation. Architects now design parametrically, allowing structures to respond to light, airflow, structural load, and environmental conditions in ways that were previously theoretical rather than practical.

What truly sets modern architecture apart is its integration with engineering and manufacturing at the earliest stages. Design is no longer handed off at the end of the process; it evolves alongside structural analysis, material science, and fabrication methods. This is where 3D printing enters the architectural conversation not as a novelty, but as a tool of precision and intent. It allows architectural ideas to exist exactly as designed, rather than being simplified to suit traditional manufacturing constraints.

There is also a fundamental shift in how value is measured. Architecture is no longer judged solely on aesthetics or cost per square metre. Longevity, adaptability, sustainability, and lifecycle performance now matter just as much. Buildings are expected to evolve, not remain static. This expectation naturally aligns with additive manufacturing, where components can be customised, replaced, or improved without demolishing entire systems.

Another defining characteristic of modern architecture is speed of iteration. Architects can now move from concept to physical model in hours rather than weeks. This rapid feedback loop improves decision-making and reduces costly mistakes later in the project lifecycle. It also empowers smaller practices and independent designers, who now have access to tools once reserved for large firms with extensive resources.

In essence, architecture today is unique because it is finally catching up with human imagination. The gap between what can be envisioned and what can be built is narrowing rapidly, and 3D printing is one of the key technologies responsible for closing that gap.

Why Architectural Constraints Are Changing Permanently

For decades, architectural constraints were treated as immovable facts: materials behave a certain way, construction follows a linear process, and deviation equals cost. That mindset is no longer valid. Constraints still exist, but they are now variables rather than fixed barriers. This change is permanent, and it is driven by digital fabrication technologies, particularly 3D printing.

Traditional construction thrives on repetition because repetition lowers cost. However, repetition also locks architecture into rigid design languages. When every component must be identical to remain economical, creativity becomes expensive. 3D printing flips this logic entirely. In additive manufacturing, variation is effectively free. Printing ten different components can cost almost the same as printing ten identical ones, provided the material volume and print time remain similar.

This single shift has enormous architectural implications. Façades can respond individually to solar exposure. Structural elements can be optimised locally rather than globally. Internal layouts can be tailored to use rather than forced into standard grids. Architecture becomes more responsive, more human, and more efficient at the same time.

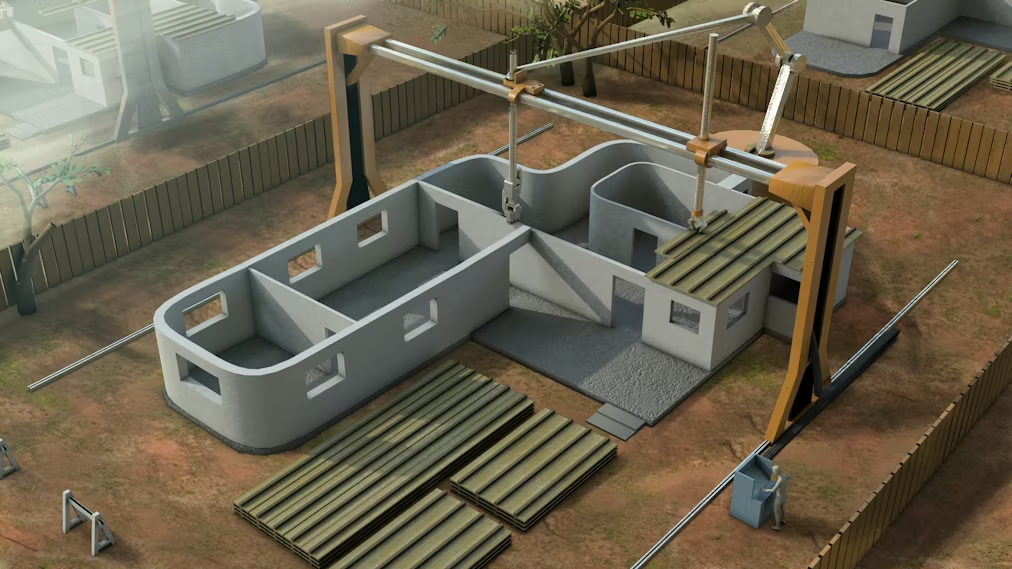

Another constraint that is rapidly disappearing is the separation between design and construction. Traditionally, architects design, engineers validate, and contractors build, often discovering conflicts too late in the process. With 3D printing, design data is construction data. The digital model becomes the instruction set for fabrication, reducing translation errors and misinterpretation.

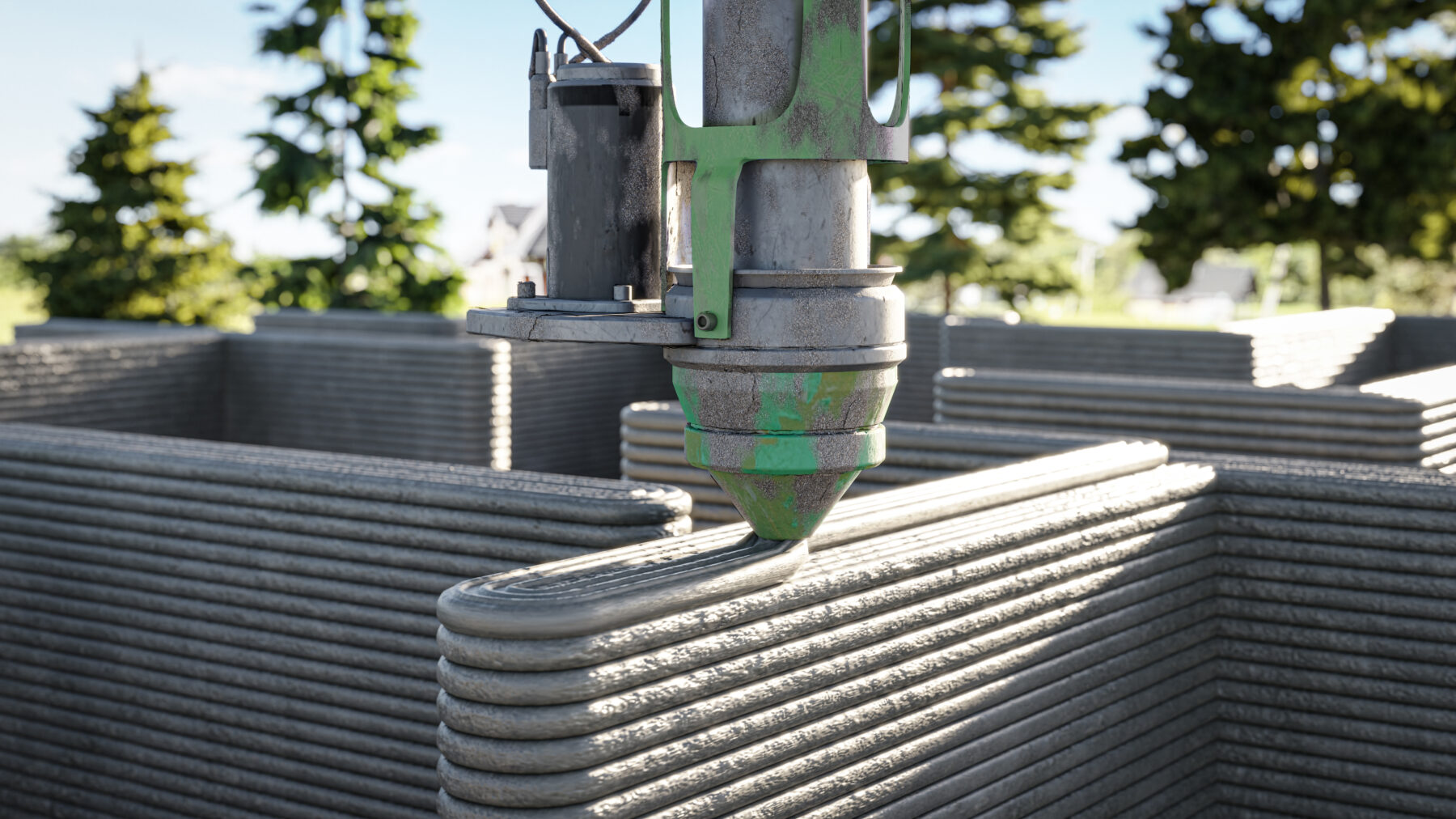

Material constraints are also evolving. Architects are no longer limited to what can be easily cast, cut, or assembled. Concrete can now be printed in complex geometries that improve strength while reducing material usage. Polymers and composites can be tuned for flexibility, UV resistance, or load-bearing performance depending on the application. This opens the door to lighter structures, reduced foundations, and lower embodied carbon.

Most importantly, these changes are not experimental anymore. They are being deployed in real-world projects, from housing to infrastructure. Once a constraint is removed at scale, it does not return. Architecture is entering a phase where the primary limitation is no longer fabrication, but imagination and intent.

Architectural 3D Printing & Rapid Manufacturing

Architectural projects demand accuracy, reliability, and flexibility—especially when designs are evolving or timelines are tight. At Mitchell & Son Additive Manufacturing, we work closely with architects, designers, and construction professionals to turn digital concepts into precise physical models and functional components. Whether you need a scaled presentation model, a bespoke fixture, or a discontinued part reproduced, we provide practical solutions that save time, reduce cost, and remove unnecessary complexity.

One of the biggest advantages of 3D printing in architecture is speed. Traditional manufacturing methods can be slow and expensive, particularly for one-off or low-volume parts. With additive manufacturing, we can move from concept to finished component quickly, without the tooling costs associated with injection moulding or machining. This makes it ideal for early-stage design validation, client presentations, and problem-solving on live projects.

Material choice is a critical part of every architectural project. We regularly work with engineering-grade plastics such as ABS, PETG, and ASA, selecting materials based on how and where the part will be used. If a component is purely visual, we can optimise for finish and cost. If it needs to withstand handling, mechanical stress, or outdoor exposure, we adjust material selection and internal structure accordingly. These decisions are always guided by real-world use, not assumptions.

We also understand that architectural components are often exposed to environmental factors such as UV light, temperature variation, and repeated handling. That is why we take the time to discuss durability and longevity at the outset. For external applications, we recommend UV-stable materials that maintain strength and appearance over time. For internal components, we focus on precision, surface quality, and dimensional accuracy to ensure parts integrate seamlessly into larger assemblies.

Every project begins with a 3D model. If you already have CAD files, we can work directly from them. If not, we can recreate or redesign components from physical samples or drawings. This capability is particularly valuable when dealing with legacy buildings, refurbishments, or systems where original parts are no longer available. In many cases, we are able to replicate components at a fraction of the cost of traditional manufacturing methods.

Quality matters. That is why we also offer post-processing services including sanding, priming, finishing, and protective coatings. These options allow architectural models and components to meet presentation-grade standards or enhanced functional requirements. Our goal is simple: to deliver parts that do exactly what they are intended to do, without over-engineering or unnecessary expense.

Architectural 3D printing is not about replacing traditional construction methods—it is about complementing them. We provide practical manufacturing support that helps architects and designers move faster, test ideas earlier, and solve problems efficiently.

How 3D Printing Integrates with Architectural Design

3D printing does not replace architectural design; it strengthens it. The real power lies in how seamlessly additive manufacturing integrates with modern digital workflows. Architects already design in three dimensions. 3D printing simply allows those designs to exist physically without compromise.

At the concept stage, 3D printing enables rapid physical prototyping. Architects can hold a building in their hands, assess proportions, study light paths, and identify issues that may not be obvious on screen. This tactile feedback improves design quality and client communication alike. Decisions become clearer, faster, and more confident.

As projects move into technical design, 3D printing becomes a tool for validation. Complex junctions, bespoke connectors, and non-standard interfaces can be printed and tested before construction begins. This reduces risk on site, where mistakes are expensive and time-consuming to correct.

In fabrication, 3D printing allows architectural components to be produced directly from the design file. There is no need for moulds, jigs, or extensive tooling. This is particularly valuable for low-volume or bespoke projects, where traditional manufacturing costs are disproportionate to the scale of the work.

The integration also extends to refurbishment and restoration. Architectural heritage often suffers from the unavailability of replacement parts. 3D printing allows components to be reverse-engineered, improved, and reproduced without altering the character of the building. This approach preserves history while using modern methods.

Crucially, 3D printing aligns architecture with sustainability goals. Material is placed only where needed, reducing waste. Components can be designed for disassembly, repair, or recycling. Architecture becomes not just something we build, but something we manage intelligently over time.

The Economic Benefits using 3D Printing

From an economic perspective, 3D printing introduces a level of efficiency that traditional construction methods struggle to match, particularly in bespoke or small-batch scenarios. One of the most immediate benefits is the elimination of tooling costs. In conventional manufacturing, moulds and formwork can cost thousands before a single component is produced. With 3D printing, that upfront cost disappears.

This changes the financial equation for architectural projects. Custom features no longer carry prohibitive premiums. Small developments gain access to high-quality bespoke elements without industrial-scale budgets. Innovation becomes financially viable rather than a luxury.

Labour efficiency is another major factor. While 3D printing does not remove the need for skilled professionals, it reduces manual repetition and on-site complexity. Components arrive ready to install, reducing delays caused by weather, site constraints, or sequencing conflicts.

Time savings also translate directly into cost savings. Faster prototyping, reduced rework, and streamlined fabrication shorten project timelines. In architecture, time is money, and every week saved can have a measurable financial impact.

Perhaps most importantly, 3D printing reduces risk. Predictable production, fewer unknowns, and earlier validation lead to more accurate cost forecasting. For developers, architects, and clients alike, this reliability is as valuable as the technology itself.

Longevity, and the Role of Additive Manufacturing

Architecture is not just about building; it is about building things that last. Longevity has become a central concern in modern design, particularly as sustainability and resource efficiency move to the forefront. 3D printing contributes to longevity not by creating disposable structures, but by enabling smarter, more maintainable ones.

Components can be designed with stress distribution in mind, reducing fatigue and failure over time. Replacement parts can be produced on demand decades later, even if original suppliers no longer exist. This fundamentally changes how buildings age.

Additive manufacturing also supports adaptive reuse. As buildings change function, components can be redesigned and replaced without wholesale demolition. Architecture becomes flexible rather than fixed, extending the useful life of structures.

In this sense, 3D printing aligns architecture with long-term thinking. It encourages buildings that evolve rather than decay, and that is perhaps its most important contribution of all.

FAQs

Is Architectural suitable for outdoor use?

It depends on UV exposure and heat. Tell us the environment and we’ll advise the best material.

Can you print Architectural for functional parts?

Yes. If you share the part purpose and any load/heat details, we’ll confirm the best settings and material choice.