Morgan 3 Wheel Classic Car

RAPID PROTOTYPING & SMALL BATCH PRODUCTION

Rapid prototyping serves as an invaluable tool for businesses aiming to swiftly iterate and test their product designs, enabling them to refine concepts and identify improvements efficiently. For small batch production runs, 3D printing technologies (FDM) and (SLS) provide a cost-effective and agile solution, enabling companies to produce limited quantities of customized components or products without the need for expensive tooling or lengthy setup times

Fused Deposition Modeling

or FDM 3D Printing

FDM printers work by heating a thermoplastic filament to its melting point and then extruding it, layer by layer, to create a three dimensional object.

FDM printers are relatively inexpensive and easy to use, making them a popular choice for home and small-scale 3D printing

Stereolithography (SLA)

Stereolithography works by using a photopolymer resin that is cured by exposure to light.

The machine traces out the desired geometry layer by layer using a computer-controlled moving laser beam.

The beam is directed by mirrors that are positioned around the build platform.

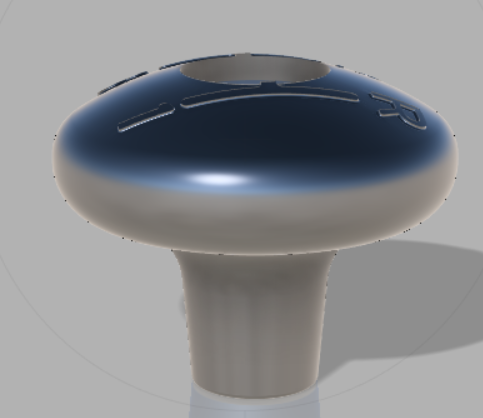

CAD DESIGN & REVERSE ENGINEERING

When it comes to certain projects, a computer-aided design, or CAD, can be extremely beneficial. A main advantage to using CAD is the fact that it provides experts with greater accuracy. This is done by replacing manual drafting with electronic design software, such as SketchUp, Fusion 360, or AutoCAD Design Edition.

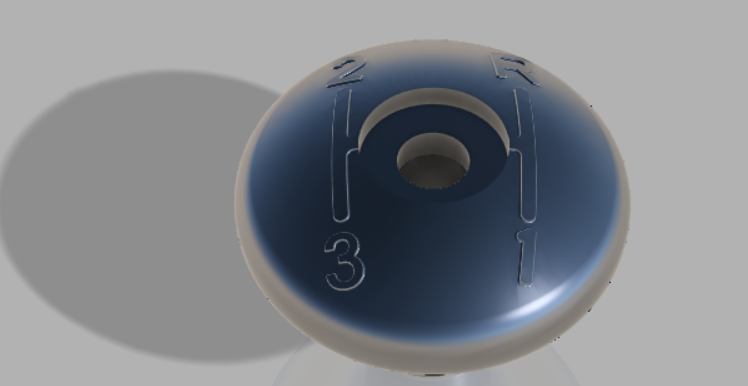

I was elated when I got the call from the Morgan 3 Wheeler Club asking our company to produce replica prototypes for them. As a car enthusiast, I was well-versed with the history of the iconic Morgan Motor Company and its legacy of engineering excellence. I knew that the very first car it had built 113 years ago was a three-wheeler. One wheel at the front for steering and two for stability, and a single drive wheel at the rear. This inspired me to take on the project.

We had to hit the ground running and over the course of the next few months, a team of engineers at our company worked hard to deliver the replica of the original Morgan three-wheeler. With a great attention to detail, we managed to recreate the look and sound of this classic vehicle, maintaining its iconic design.

To my surprise, the replica was met with an overwhelming response from the public. The three-wheeler quickly became a hit amongst car collectors, adrenaline-seekers and those who appreciated the craftsmanship and engineering prowess of Morgan Motor Company.

What I saw as the success of our project was not just about the car itself but about how it brought people together. And I take pride in the fact that we played a role in that. Now, Morgan Motor Company is preparing to roll out the all-new 2023 Morgan three-wheeler, and I am sure that it will be its most important yet.

I was always fascinated by the Morgan Motor Company and it's storied history. I had the great fortune to be asked to create a 3D model of a casting mould as a prototype for a future project for the company. I was extremely excited to be offered such a unique opportunity.

When I began to research the company and its history I was fascinated to discover that when the company was first established 113 years ago, the car they made was a three-wheeler. Even more remarkable was the fact that they only made three wheelers until 1936.

I felt a renewed sense of enthusiasm as I worked on the Morgan three-wheeler. I knew that this new three-wheeler needed to be a cut above the rest, and with this in mind, I poured my heart and soul into creating the perfect prototype.

I took great pride in my work and I was extremely pleased with the end result. After weeks of working on the project, I was sure that the new Morgan three-wheeler was going to be the company’s most important yet. With this in mind, I eagerly awaited the official launch date to see the positive reaction that I was sure the public would have to this iconic vehicle.

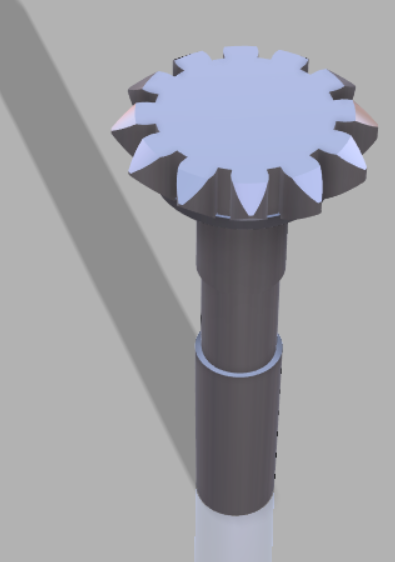

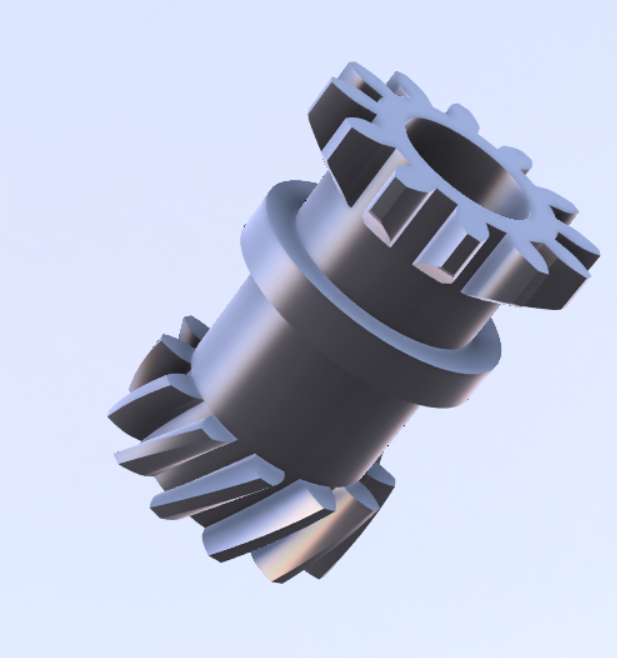

I had the unique experience of being asked to reverse engineer a gear set for a classic Morgan 3 Wheeler. After all, the 3 Wheeler has been around for over one hundred years and it would be an incredible honor to work on such a historic vehicle.

I had always been a fan of classic cars so I was excited to get started. But when I looked at the project, I couldn't help but feel a little intimidated. The speedo drive seemed to be a complex system and I had no experience working with such technology.

I set out to learn as much as I could about the speedo drive and the 3 Wheeler. I researched old manuals, read up on the history and mechanics of the car, and studied diagrams of the speedo drive setup. As I worked, I gradually began to wrap my head around the intricacies of the drive.

Hours of research and careful observation later, I was ready to get to work. I used CAD software to virtually reverse engineer the gear set for the speedo drive and then 3D printed the end product. The printed parts were made of tool steel, giving them strength and durability for the long run.

When I finally installed the new gear set on the Morgan 3 Wheeler, I felt a great sense of accomplishment. The car was ready to hit the road again and be a part of the Morgan family's rich history. I smiled, thinking of all the adventures the 3 Wheeler might have ahead of it.

It truly was a privilege and an honor to work on a vehicle that was made a century ago but was still thrilling to drive. It seemed to have an energy that was impossible to replicate and I was proud to be a part of its journey.