3D PRINTING SERVICE |3D SCANNING | 3D MODELS

Give us details of your project using this form

Join our growing list of trusted customers

RAPID PROTOTYPING & SMALL BATCH PRODUCTION

INSTANT ONLINE QUOTES

PRODUCTION LEAD TIMES: 5 - 10 WORKING DAYS

CAD DESIGN & REVERSE ENGINEERING

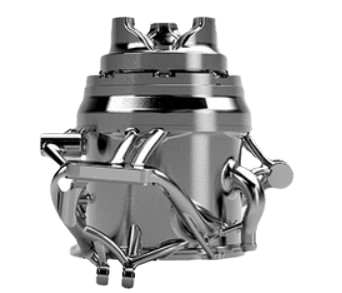

LOST WAX CASTING WITH 3D PRINTING TECHNOLOGY

Investment casting is a manufacturing process that has many benefits over other methods. It can be used to produce objects that are made from materials such as cast iron and aluminum. The process of lost wax casting is also much simpler than other methods, and it results in a more accurate reproduction of the object.

In addition, the process is less likely to damage the object during the manufacturing process. 3D printing is another manufacturing technology that offers many benefits over traditional methods. It is a faster and more efficient way to produce objects, and it can be used to create objects with very intricate designs. 3D printing is also less likely to damage the object during the manufacturing process.

Metal 3D printing is a newer technology that offers even more benefits over traditional methods. It is a faster, more accurate, and less expensive way to produce objects. Metal 3D printing is also less likely to damage the object during the manufacturing process.

OUR BUSINESS CUSTOMERS

Rapid prototyping to small batch production

Rapid prototyping

Our platform accelerates prototyping development cycles by reducing pre-production admin from weeks to minutes:

- Instant quotes

- Instant feedback

- Online quote and order management

Our process is designed to be so intuitive that you can order your parts quickly and efficiently without any assistance. But if you ever need us, we're here to help.

Production

For production orders, we have full-service teams ready to guarantee identical specs on every order for the best unit price:

- Dedicated project managers

- Application engineers for cost optimisations

Manufacturing is about relationships, so we have staff on the ground wherever you are to help make sure everything runs smoothly and on time, every time.

Yesterday is gone, Tomorrow is always a day away, so put your product into production today

Frequently asked Questions

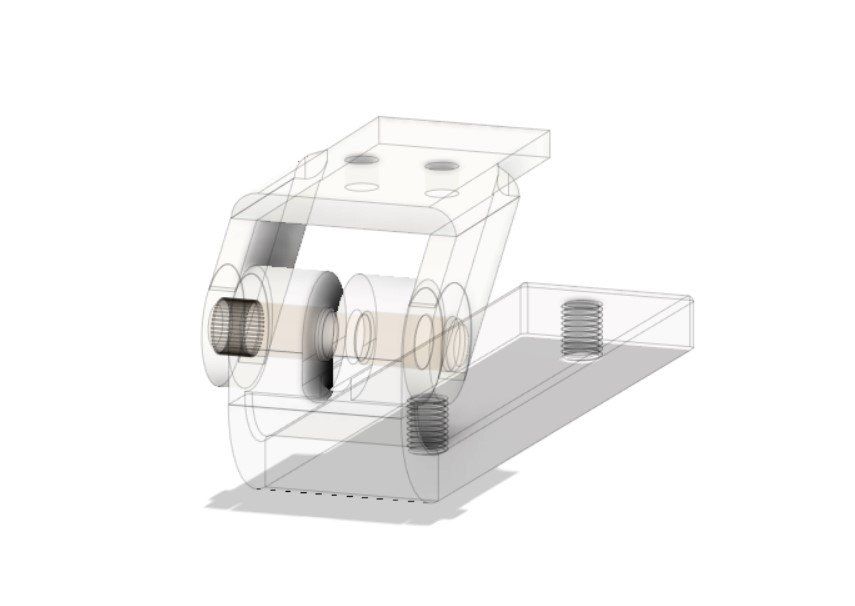

Rendering the Design

Do you have a 3D design that you want to showcase?

Rendering is the perfect way to see your ideas in action. With realistic textures and lighting, you can create truly lifelike models that look just like the real thing. Whether you're creating a new product or redesigning an old one, rendering is the perfect way to see your ideas in action.

We offer high-quality rendering services for all of your needs! Whether it's for product design, architectural design, or anything else - we've got you covered. We'll deliver the best possible results with our team of professional designers and artists who are ready to take on any project.

Click now and learn how we can aid you with your project

What are the Benefits

1. With 3D rendering Software, you can create realistic-looking models of anything you like!

2. This software uses three dimensions to represent objects, making for a more lifelike end result.

3. You can use it to create models of anything, from everyday items to imaginary creatures or landscapes.

4. 3D Scanning make the process of visualising the parts as a 3D Model easier.

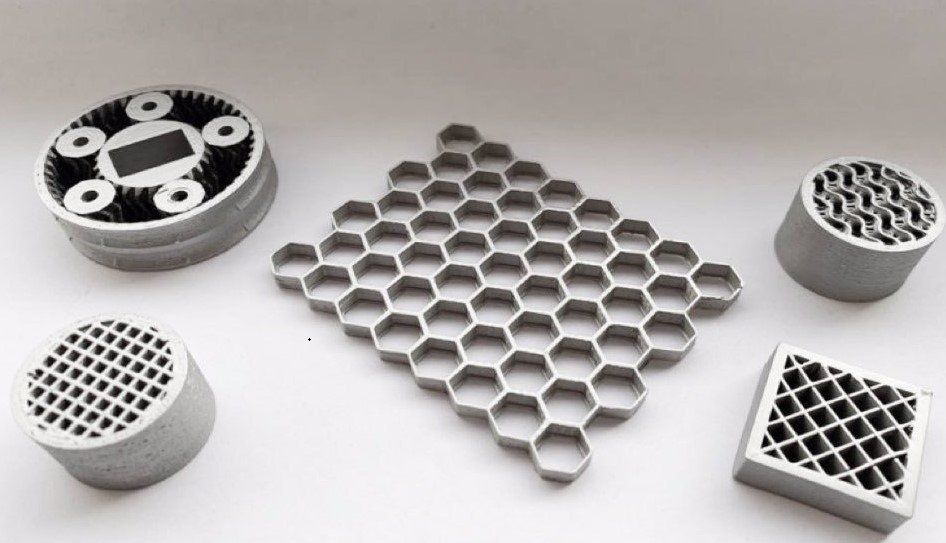

The most common 3D Printer:

The FDM printer is the most common type of 3D printed object you'll find at home or in schools. This technology has been used for years by designers, engineers and architects to create models that can be tested before being manufactured into full size objects

What makes it so versatile? First off there's no need constantly monitoring feed rates because everything happens right here on this surface - all your model needs are some basic furnishings such as nuts & bolts; if they don't have those already then simply grab an bunch from any nearby store!

It works by heating up and extruding a filament of plastic, which is then deposited in layers to create a 3D object. The FDM process can create objects from many different types of plastic including PLA and ABS.

List of Technology terms:

- FDM => Fused Deposition Modeling ( Desktop 3D Printer)

- SLA => Stereolithography

- MSLA = > Masked Stereolithography

- SLS = > Selective Laser Sintering

- DLP => Digital Light Process

- MJF => Multi Jet Fusion

- DMLS => Direct Metal Laser Sintering

- EBM => Electro Beam Melting

- PBF = > Powder Bed Fusion ( sometimes also referred to as MJF)

Reverse engineering

Reverse Engineering is a process which enables users to create an exact replica of any object or part with the help 3D printing. With this technology, you can 3D scan your desired item and convert it into CAD file for printing on compatible machines using additive manufacturing techniques like 3D Printing. The output should be more creative 3D printing has been changing the world of manufacturing for years.

Reverse engineering is one way that this technology can be put to use- enabling users not only print out copies or spare parts from their own objects but also those which are otherwise hard find and expensive in stores! is the process of recovering the original design from an existing product. It is used to create copies of existing products, or sometimes it can be used to modify an existing product. is the process of discovering the technological principles of a device, object or system through analysis of its structure, function and operation

Rapid prototyping:

It is usually applied to extract useful information from products under study. It is also used to create new products and production methods.

Using 3D printing technology, we can produce prototypes of the original product on a smaller scale, which is faster and more cost-effective than

The process involves taking measurements of the existing product and then using those measurements to create a replica in CAD. This is then modified until it matches the original design. Often times the replica part would need alterations to the traditional design and be modified and would need designing for 3d printing due the manufacturing method applied

This process has three stages: implementation, design and analysis. In the first stage -implementation-, you need to quickly learn about your application in order for it not be too much of a challenge on top what may already seem like an impossible task at hand! Quickly get prepared by researching all aspects that are relevant before moving onto step two (design) or even just taking some time out during this period where everything will become clearer once more when done correctly later down life line

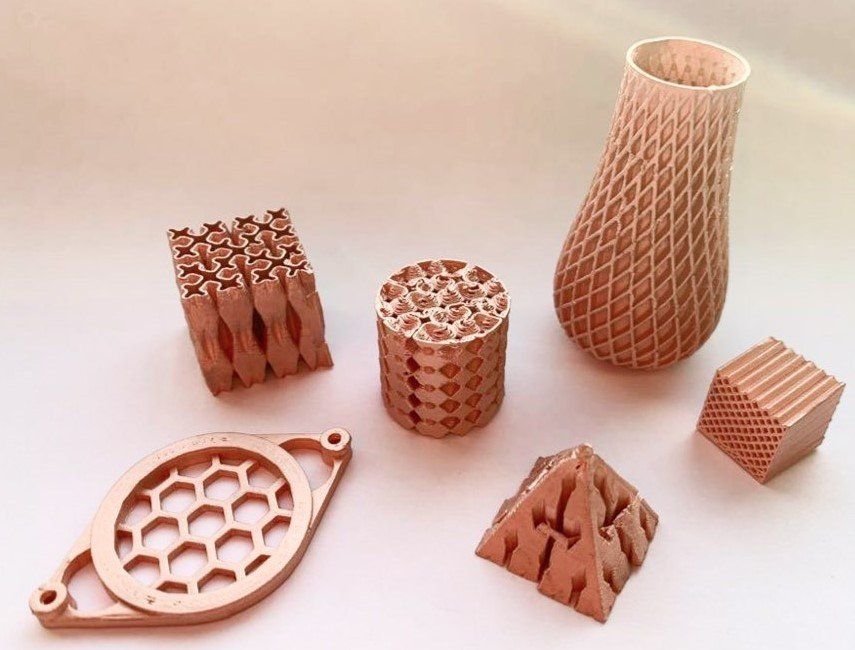

Examples of other Materials used

- Copper

- 17-4 PH Stainless Steel

SOME OF THE MORE COMMON 3D PRINTED MATERIALS

Do you need a prototype or production part?

Our 3D Printing Service is perfect for businesses that need to create prototypes quickly and easily. We offer a 75% reduction in production time, making it the perfect solution for businesses that need to get products to market quickly. Our service is also great for designers, engineers and product developers who need to create prototypes easily and affordably. We use the latest 3D printing technology to produce high quality metal parts, and our team of experts can help you design and manufacture your products using the latest 3D printing technology. Contact us today to learn more about our 3D Printing Service!

Advantages:

- We can CAD design and 3d print parts faster than ever before

- You will have a part that meets all of your requirements.

- You will save time and money on the design and manufacturing process.

- Transform your business with custom 3D Printed parts.

- Spare parts are made according to customer specifications

- Parts are made from high quality materials

- You're a part of the CAD design process!

- Get the exact item you need for your project.

- You'll be able to create whatever you want with our CAD / 3D Printing service.

- Local Service in your area

Metal 3D Print Service

What Is FDM (fused deposition modelling) 3D Metal Printing?

FDM is a type of additively manufactured durable product that can be produced with either metal or plastic filaments. The name describes how these materials are fused together during printing process by being melted and then extruded through nozzles like objects inside your home printer! This technology has been around since 1986 but was revolutionary enough back then to warrant its own article; read on if you want talk about what makes this method unique among others out there today.

3d printing in the UK, went "Viral" from end of 2019 and was thrown into the lime light due to COVID-19 out break becoming a vital tool in the fight against the virus in the beginning stages

Can FDM Plastic Filament 3D printers also be used for metallic filament?

Some people think that FDM 3d printers can only use plastic filaments, but it's possible to use for this purpose also. You just need an extra nozzle and some slicing software So what would be the advantages of using such printing technologies? Well for starters they're efficient because no energy is lost during production process; also there are less restrictions on material compatibility since this technique allows us go pretty much anywhere within reason when making physical objects from different alloys or even completely non-living substances like clay!

Sintering

Sintering, a natural process used to form solids through heat and pressure without melting the material into liquids or gasses is one way that minerals can be deposited on other surfaces. This technique has been widely applied in industries such as ceramics manufacturing where it produces strong durable pieces with incredible detail while maintaining their shape over time - perfect for any collection!

Read Our Latest Articles