Multi Jet Fusion (MJF)

There are two main types of 3D printing technology: material jetting and material extrusion. Each has its own advantages and disadvantages, but the main difference between the two is the heat source.

SLS uses a laser to scan and sinter each cross section, while in MJF an ink (fusing agent) is dispensed on the powder that promotes the absorption of infrared light. An infrared energy source then passes over the building platform and fuses the inked areas.

MJF is generally considered to be more precise than SLS, and is better suited for complex geometries. It is also slower, and the build platform must be heated to a high temperature (around 200 degrees Celsius) in order to properly fuse the powder.

SLS, on the other hand, is faster and can be used with a wider variety of materials. The build platform does not need to be heated, as the laser itself is used to raise the temperature of the powder. However, SLS is less precise than MJF, and the finish quality is not as good.

MJF is the superior technology for most applications, but SLS has its advantages as well. It really depends on what you need the 3D printed object for as to which technology is best suited.

3D printing technology has come a long way in recent years. Multi Jet Fusion (MJF) 3D printing is now being used in a variety of applications, from manufacturing and medicine to architecture and custom art and design.

MJF 3D printing is particularly well-suited for manufacturing applications. It can produce parts with very tight tolerances, and the parts can be made from a variety of materials, including metals, plastics, ceramics, and glass.

MJF 3D printing is also being used in medicine, for both prosthetic devices and implants. The ability to print complex shapes in medical-grade materials means that MJF 3D printing can create customised devices that are perfect for each patient.

Architecture is another area where MJF 3D printing is having an impact. The ability to create complex, free-form shapes means that MJF 3D-printed buildings can have a truly unique appearance. And, because MJF 3D-printed parts can be made from a variety of materials, they can be used to create buildings that are both beautiful and functional.

The applications of MJF 3D printing technology are limited only by the imagination. As the technology continues to develop, it will no doubt find even more uses in the years to come.

Multi Jet Fusion (MJF) – High-Performance Polymer Printing

Next-gen industrial 3D printing for fine detail, consistency, and scalability

Introduction

Multi Jet Fusion (MJF) is the future of polymer additive manufacturing — faster, cleaner, and more capable than traditional powder-bed printing. It delivers superior mechanical properties, consistent part quality, and true scalability.

If you're a design engineer, buyer or manufacturer looking for a step up in production-ready printing — MJF is your new best friend.

What is MJF?

Developed by HP, Multi Jet Fusion uses fusing and detailing agents deposited by inkjet heads over a bed of nylon powder. An infrared lamp then passes over the bed, sintering the powder where needed. Unlike SLS, MJF builds incredibly fine layers with near-isotropic strength, resulting in tougher, more uniform parts.

Key distinction? Speed and detail. MJF is significantly faster than SLS, and the finish is far more consistent.

Technical Specifications (MJF)

▸ Layer Thickness:

• 80 microns standard

• High-resolution print quality with crisp edge fidelity

▸ Material Properties:

• PA12 Nylon: industry standard for toughness, abrasion resistance

• Optional PA11, PA12 Glass Beads, TPU for flexibility

▸ Dimensional Accuracy:

• Tolerances as low as ±0.2 mm

• Excellent for assemblies, snap fits, and precision housings

▸ Finish & Appearance:

• Matte grey finish (pre-dyed), smooth to touch

• Uniform colour and density throughout the build

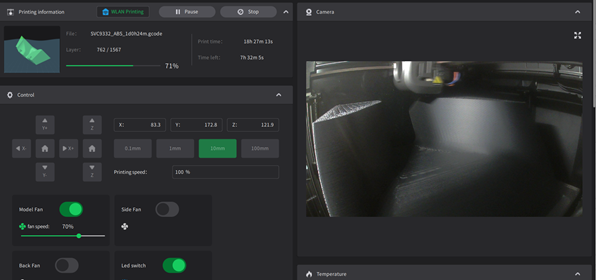

▸ Production Capacity:

• Batch printing of hundreds of parts per build

• Excellent repeatability across parts

MJF delivers consistent strength and surface quality that rivals injection moulding — without the tooling cost.

Where MJF Thrives

1. Production-Grade End-Use Parts

MJF delivers injection-moulding-like performance straight from the printer.

• Wearable enclosures

• Load-bearing brackets

• Industrial ducting, mounts, casings

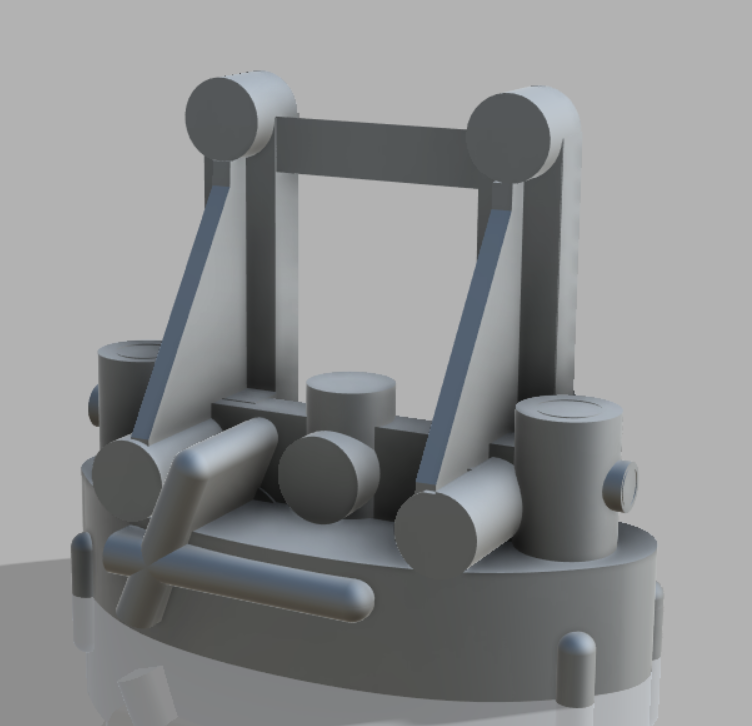

2. Complex, Lightweight Structures

With internal lattices and consolidated assemblies, you can:

• Reduce weight without compromising strength

• Simplify complex BOMs

• Eliminate assembly steps by printing as one part

3. Custom Manufacturing Solutions

Buyers turn to MJF for low-volume, high-quality production.

• Personalised, high-mix manufacturing

• One-off spares and legacy part reproduction

• Robust tooling that holds up on the factory floor

At Mitchell & Son, we use MJF to solve problems faster than suppliers can restock — particularly during supply chain delays or obsolete part shortages.

Why Engineers Love MJF

✔ Faster than SLS and more consistent

✔ High-strength parts with fine resolution

✔ Ideal for production environments

✔ Better part-to-part repeatability than other powder bed systems

MJF combines the speed of inkjet technology with the durability of sintered nylon, offering design engineers a reliable path to real-world production parts.

Summary

MJF is redefining what’s possible with polymer 3D printing. It combines speed, consistency, and strength to create production-quality parts with zero compromise. For engineers and manufacturers looking to bridge the gap between prototype and production, MJF offers a futureproof, scalable solution.