CAD DESIGN SERVICES REVERSE ENGINEERING SERVICES

Our services include: Reverse Engineering and Design Services, Machine Tooling and Manufacturing Services, CNC Machining and Turning Services, Plastic Injection Molding Services, Large-scale Metal Casting Services, Prototyping Services

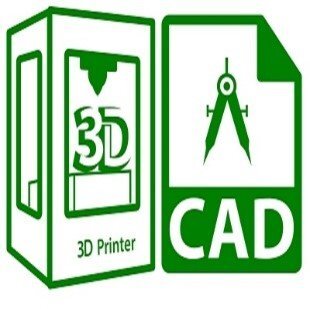

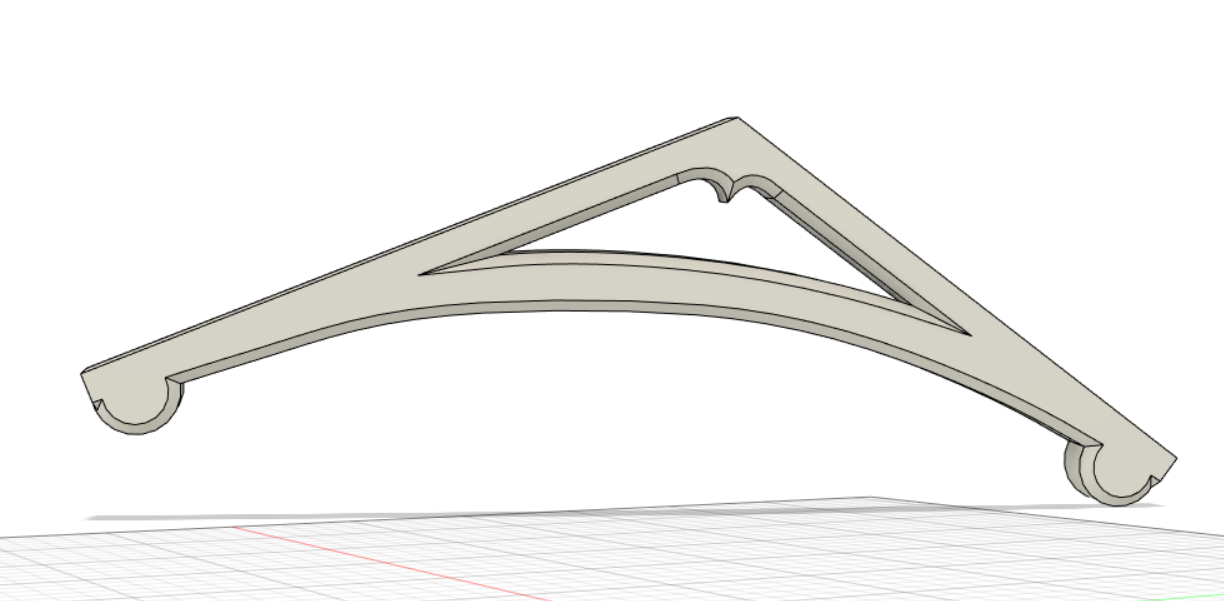

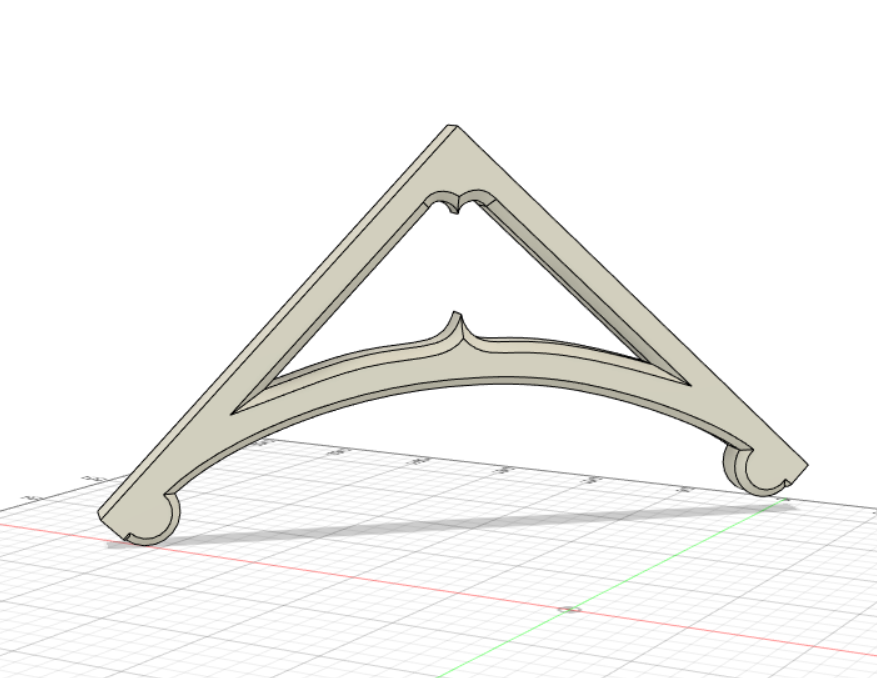

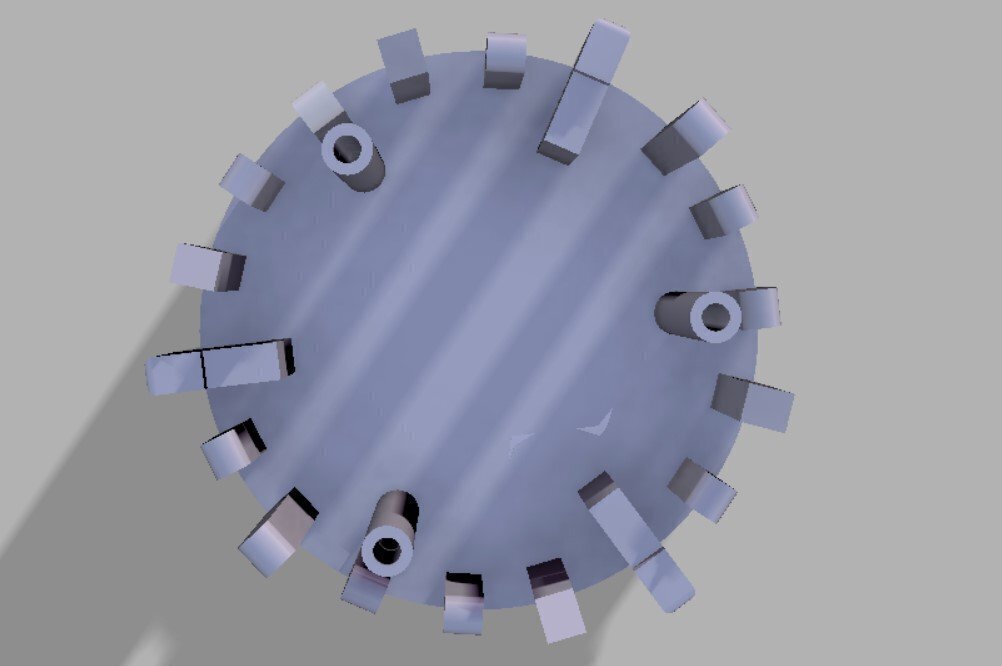

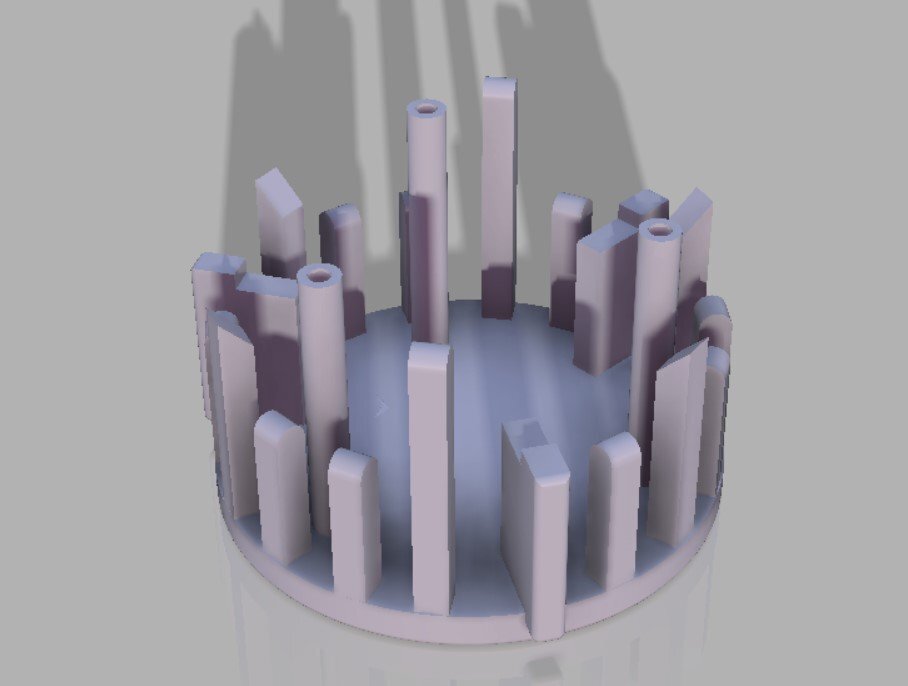

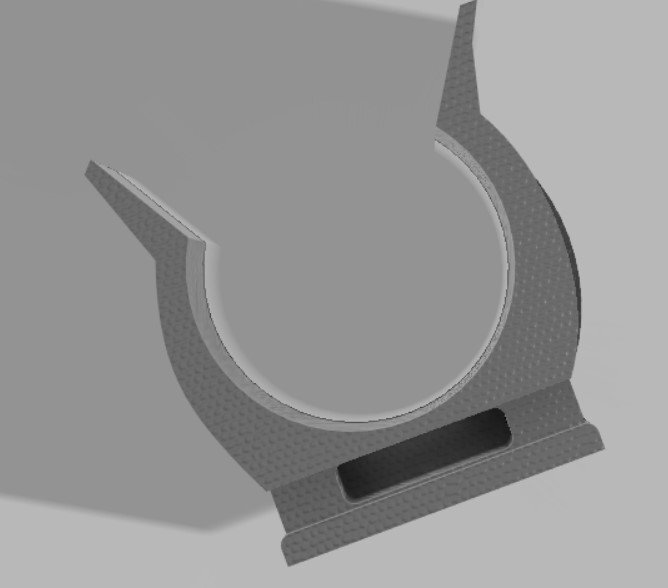

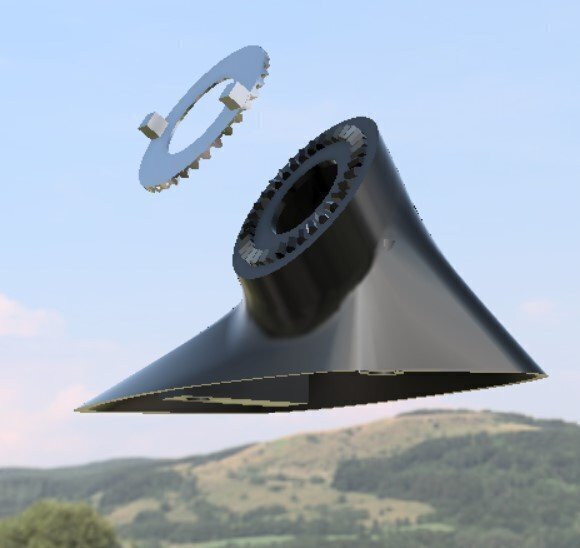

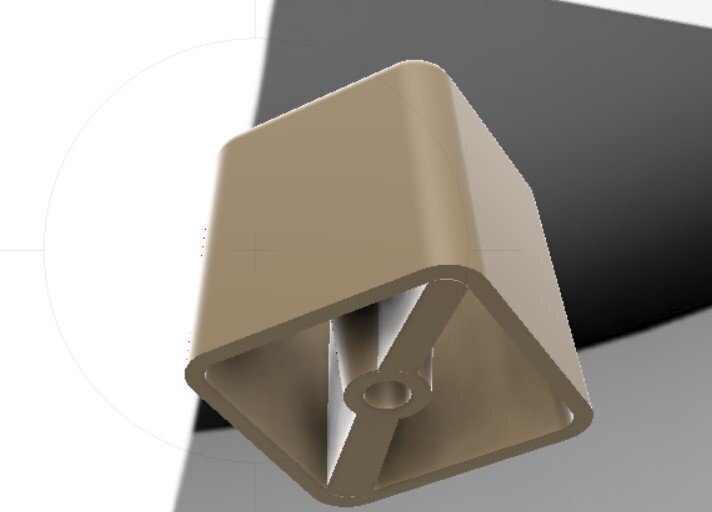

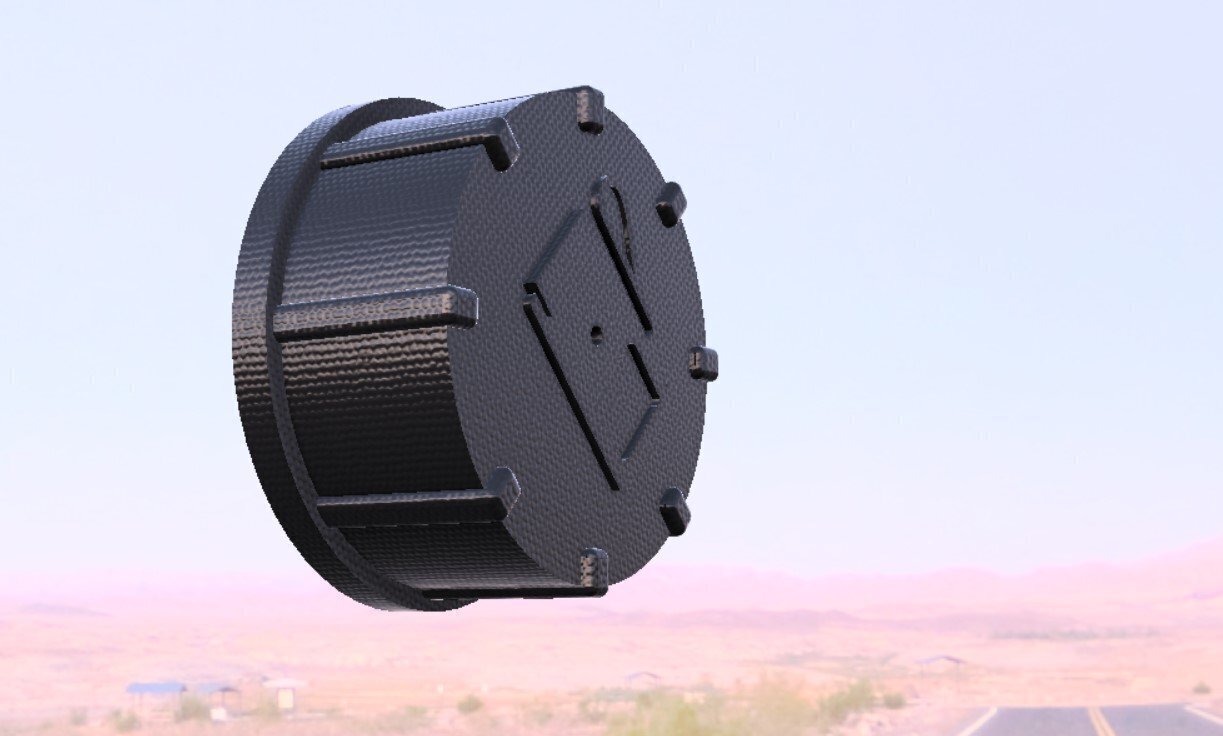

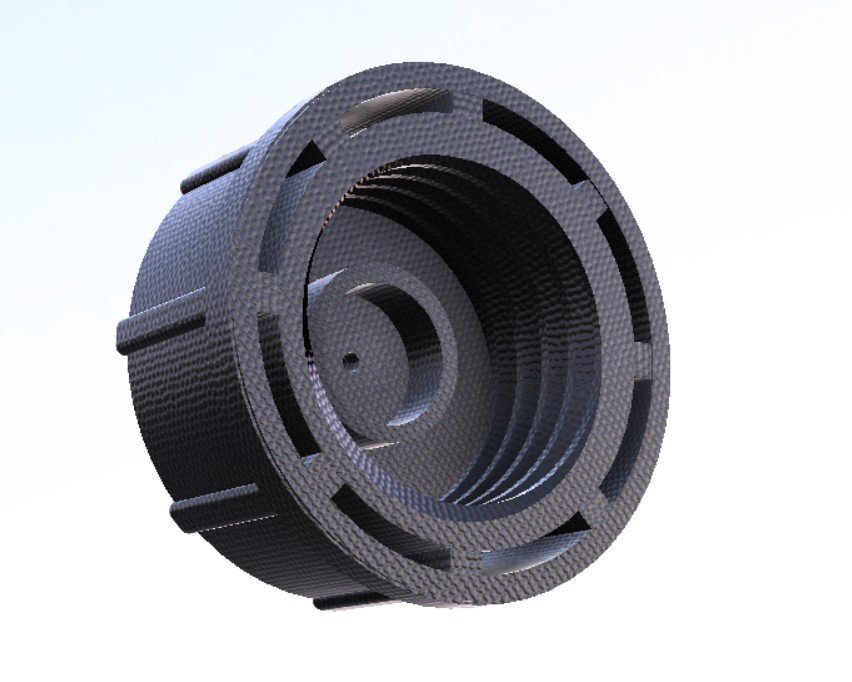

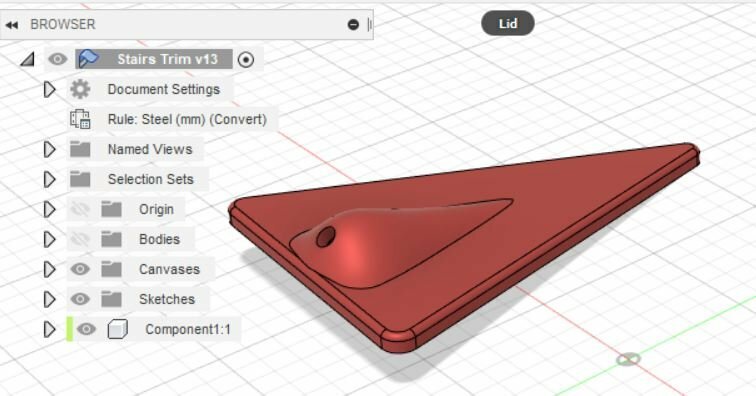

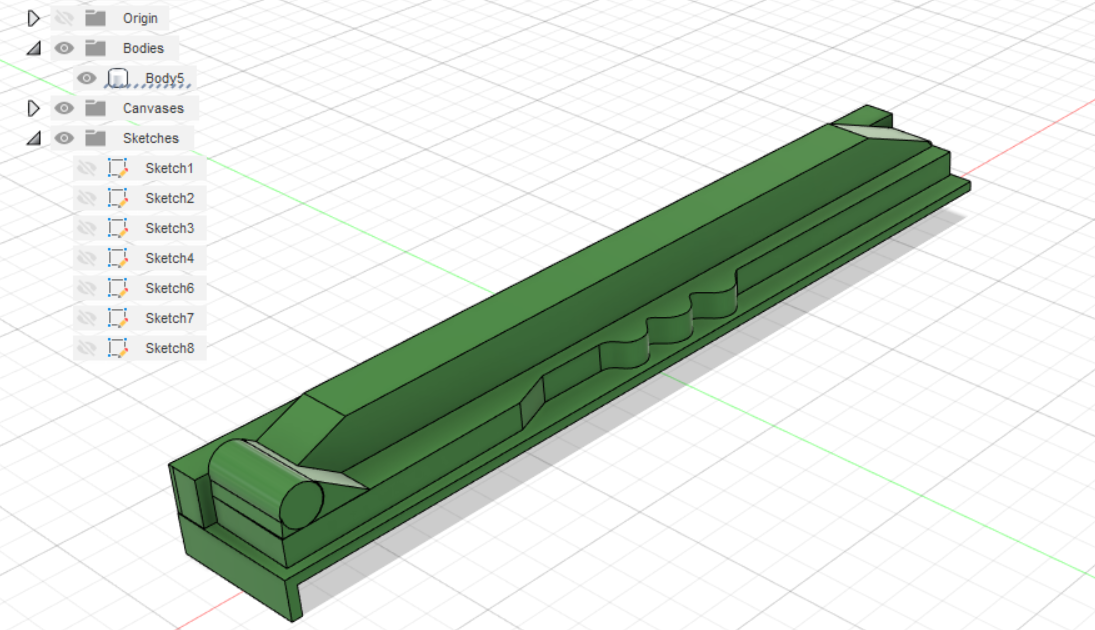

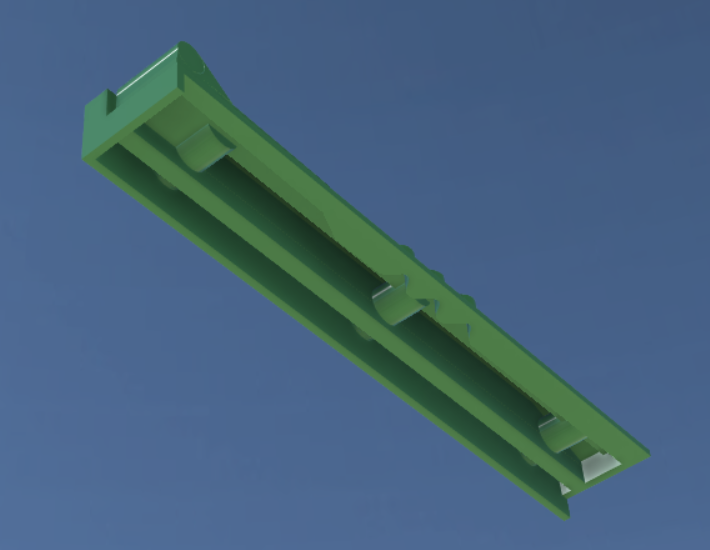

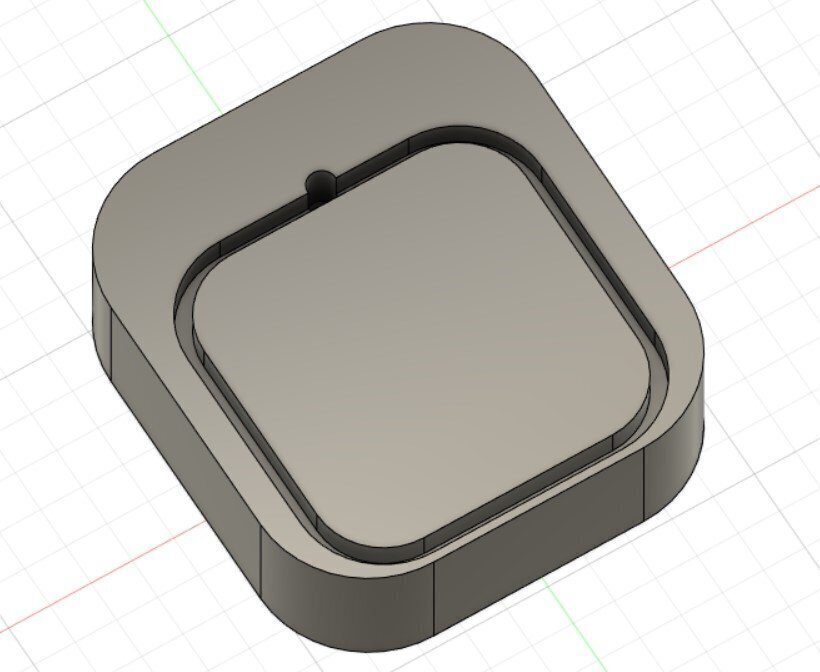

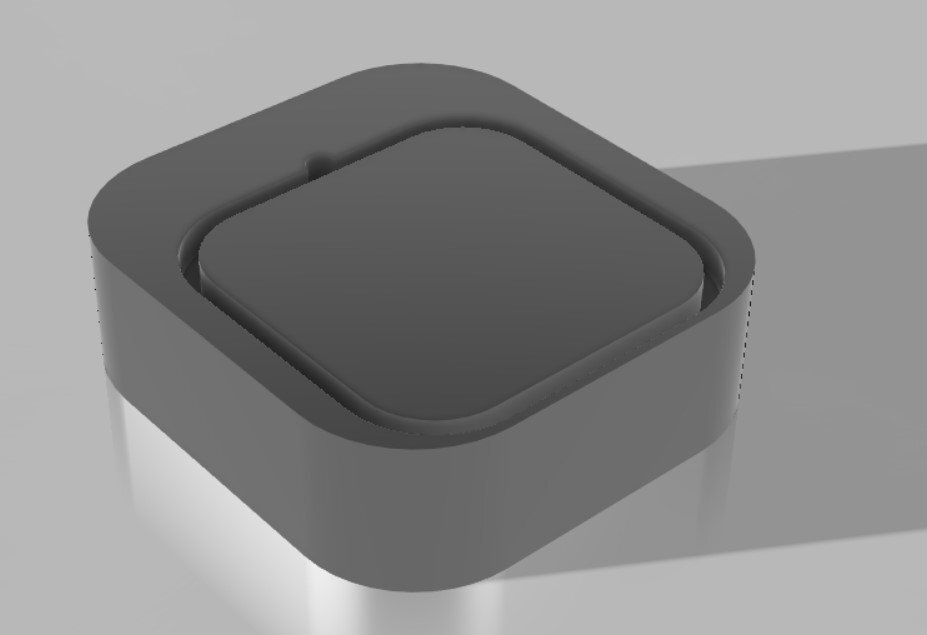

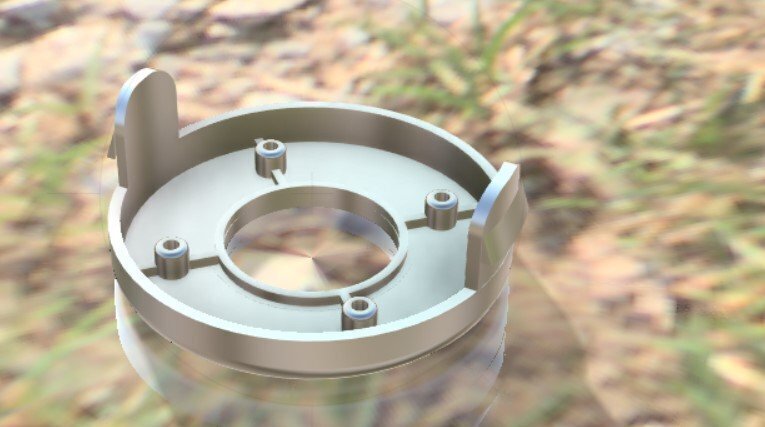

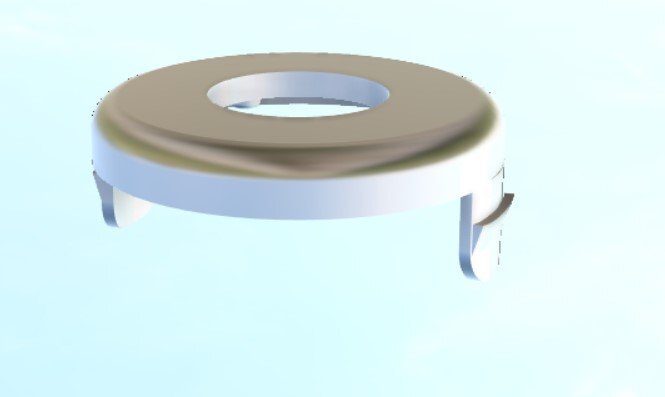

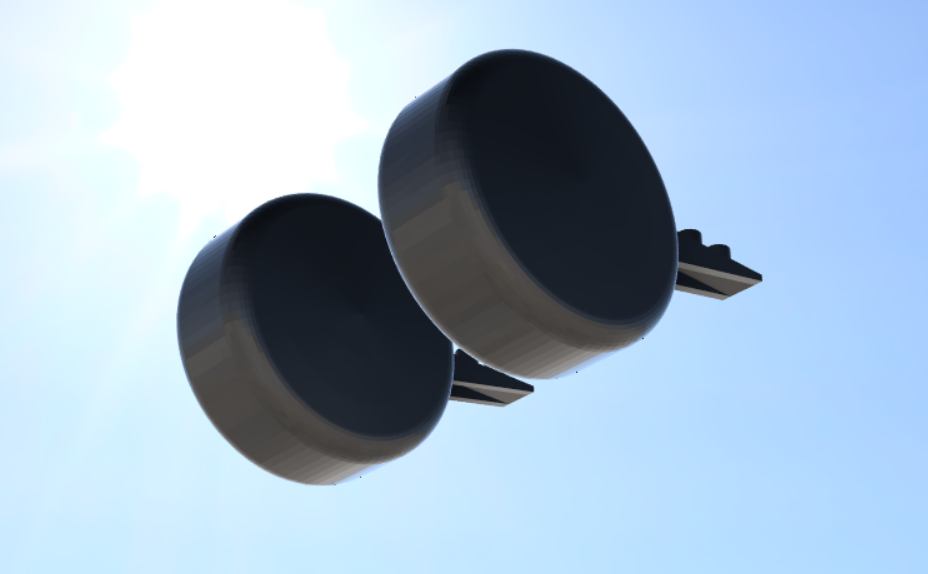

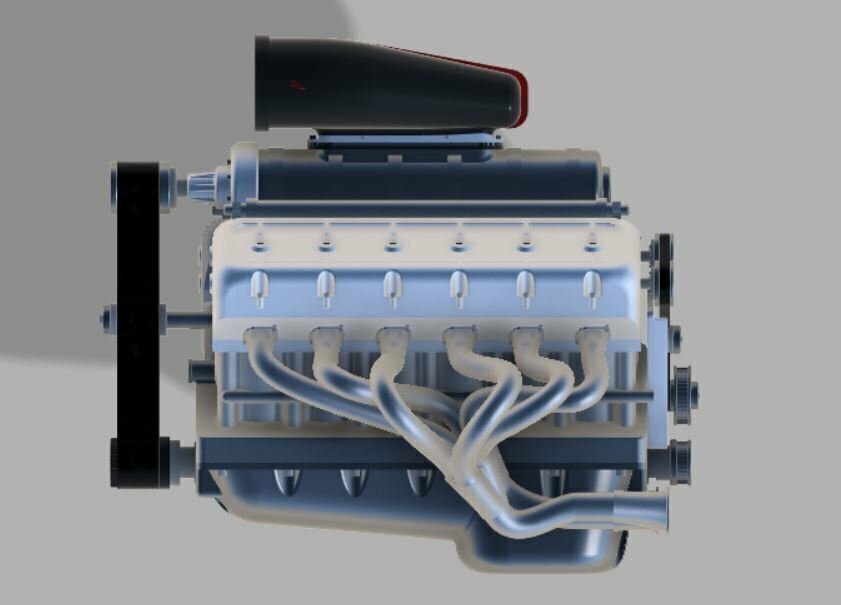

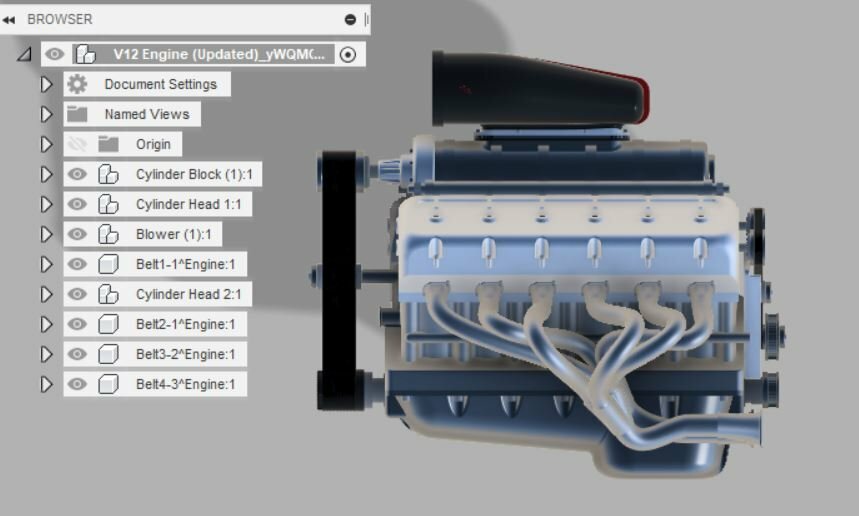

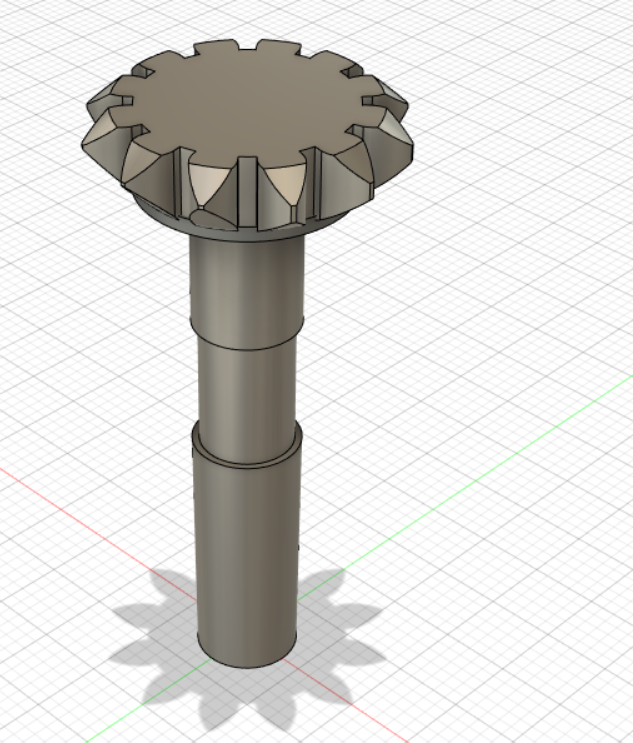

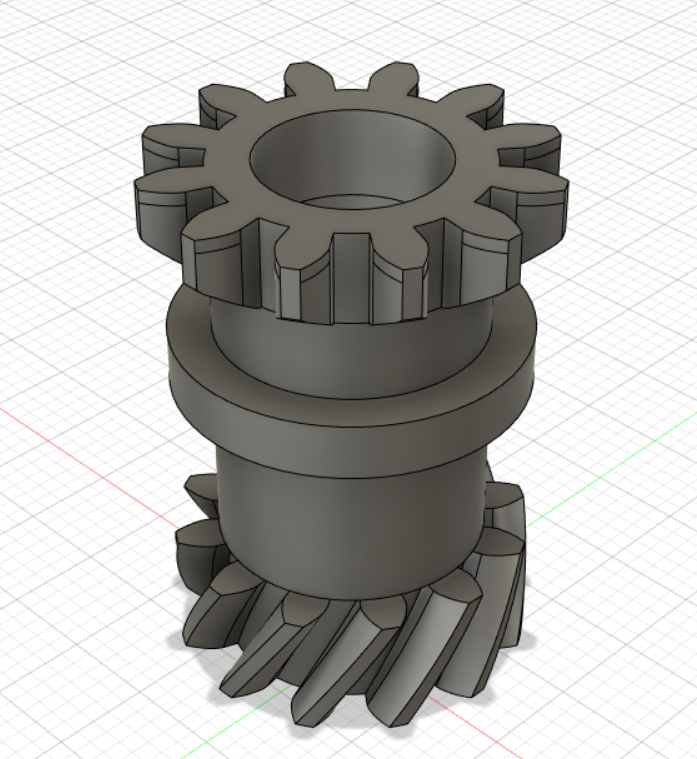

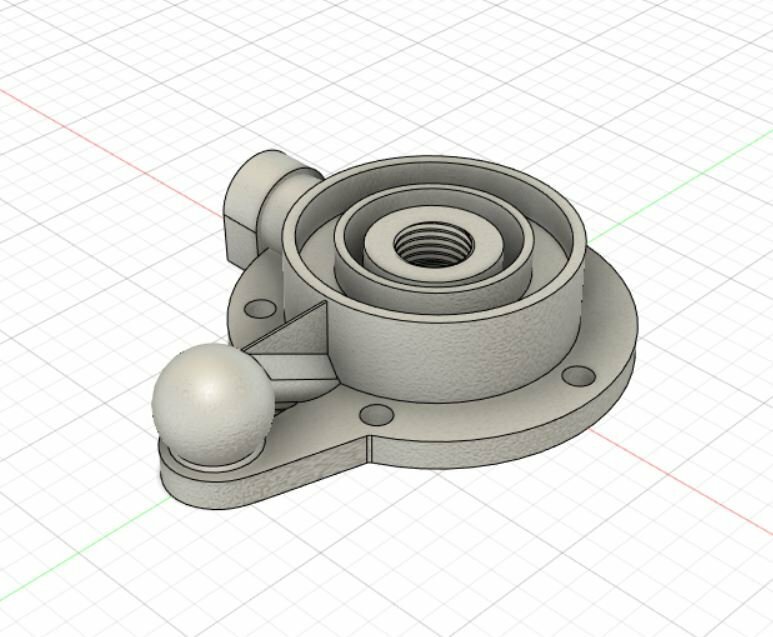

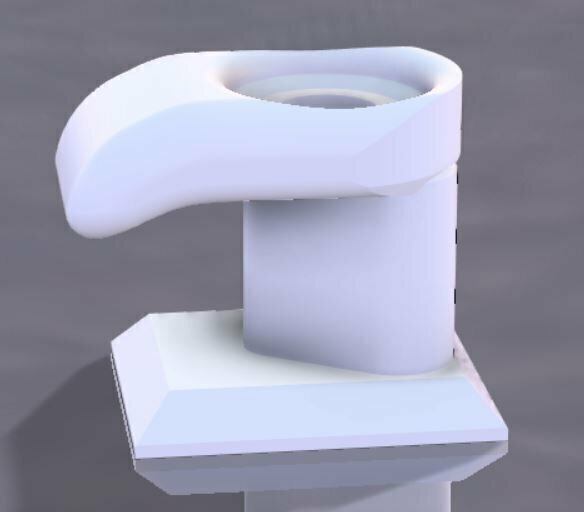

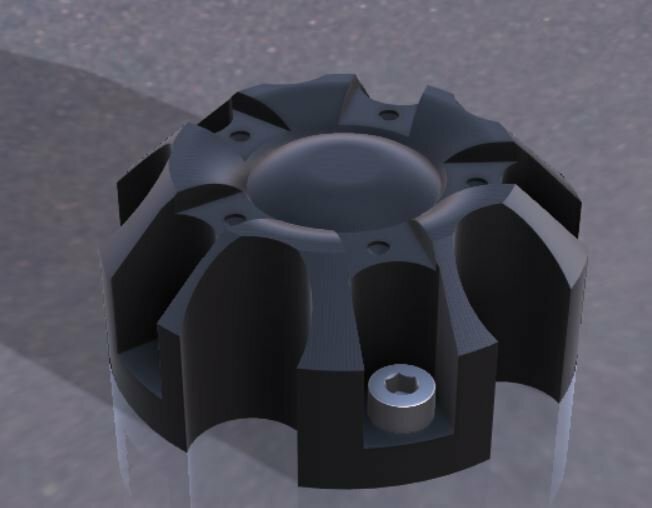

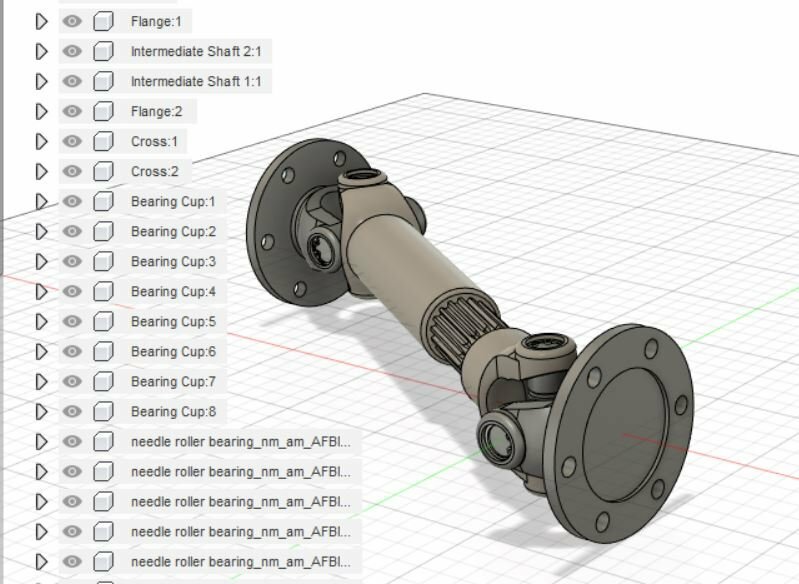

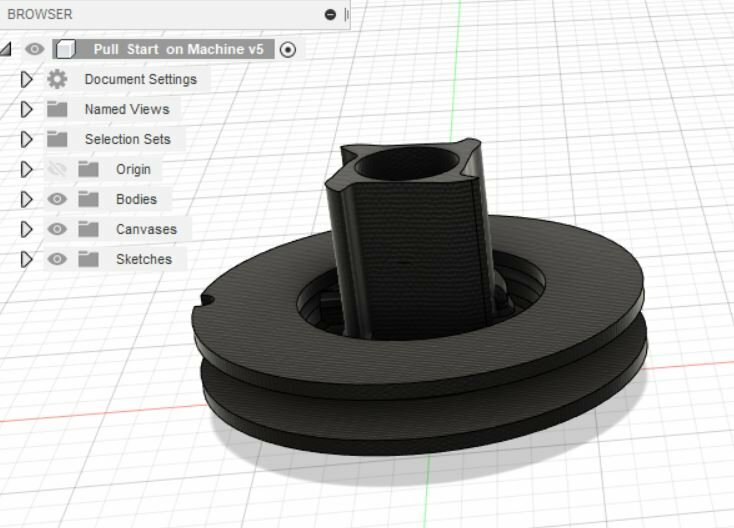

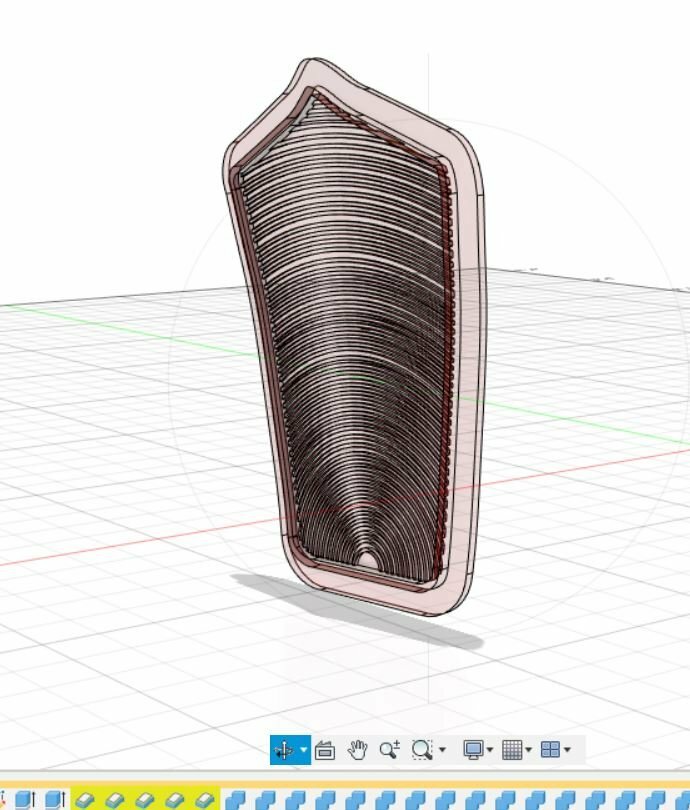

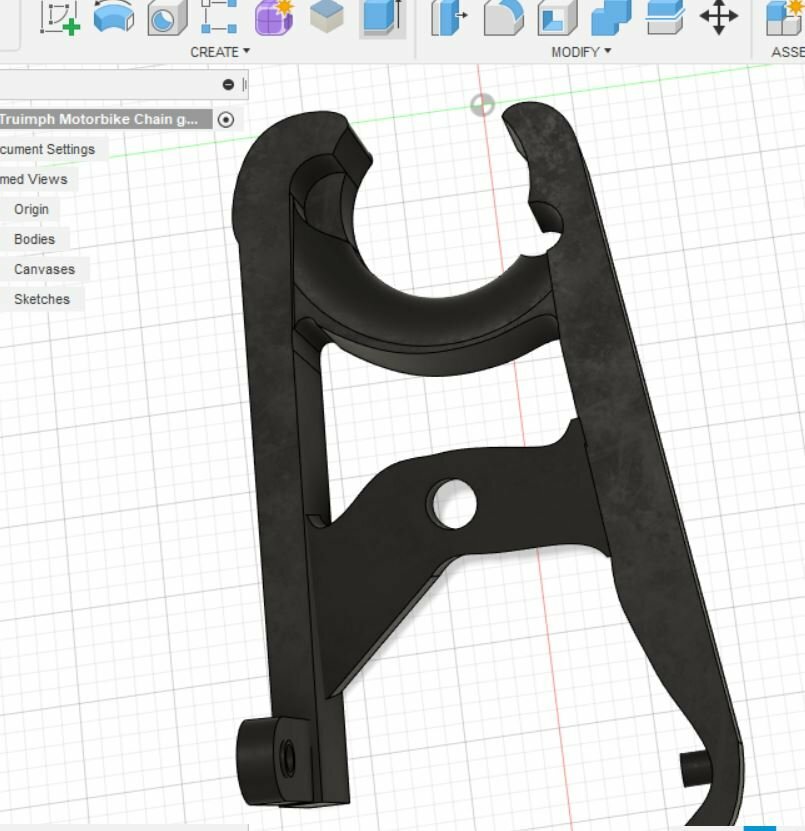

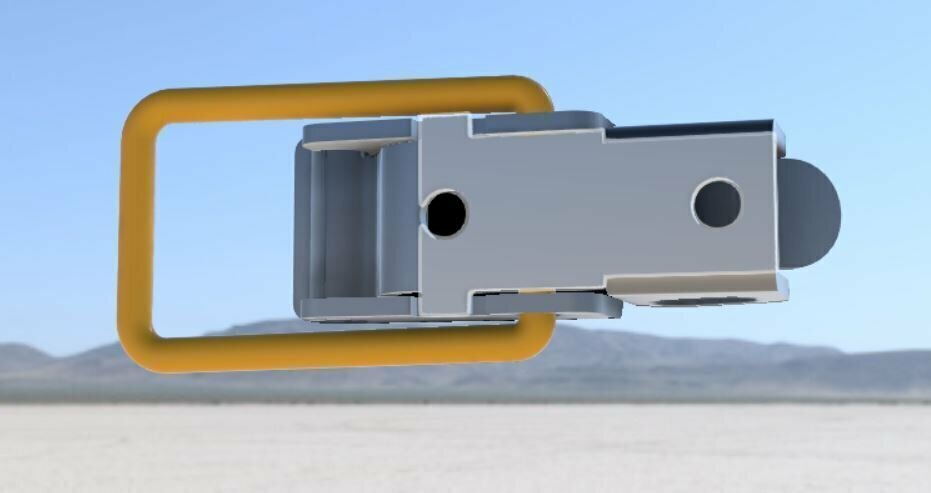

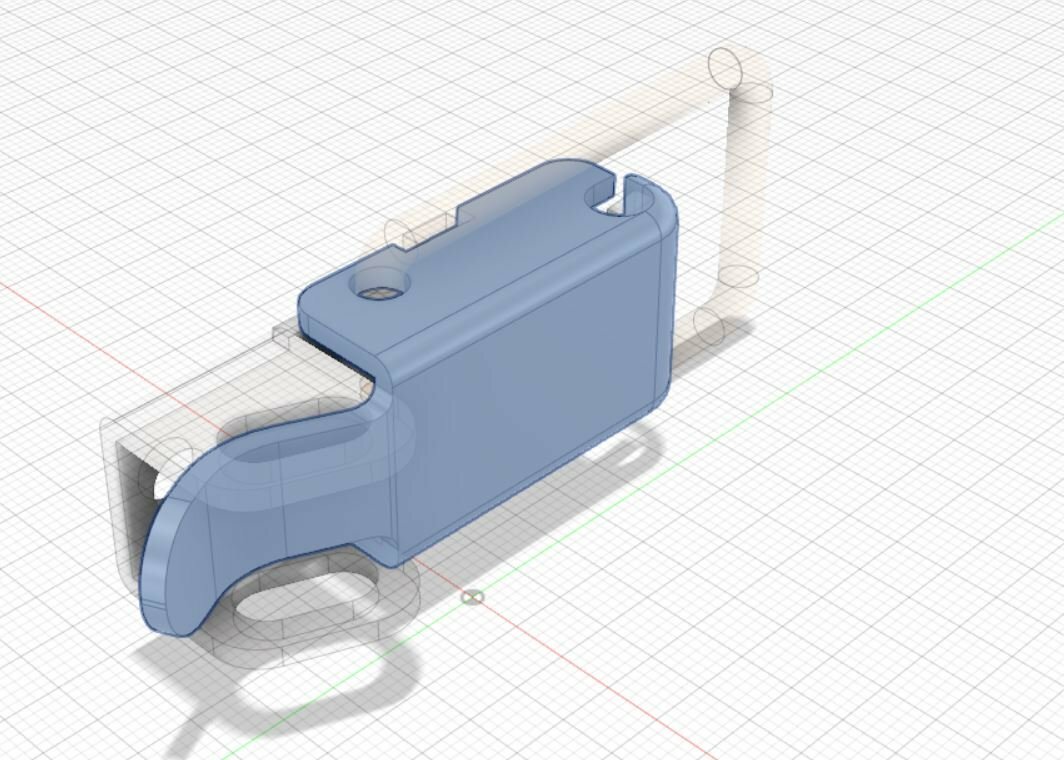

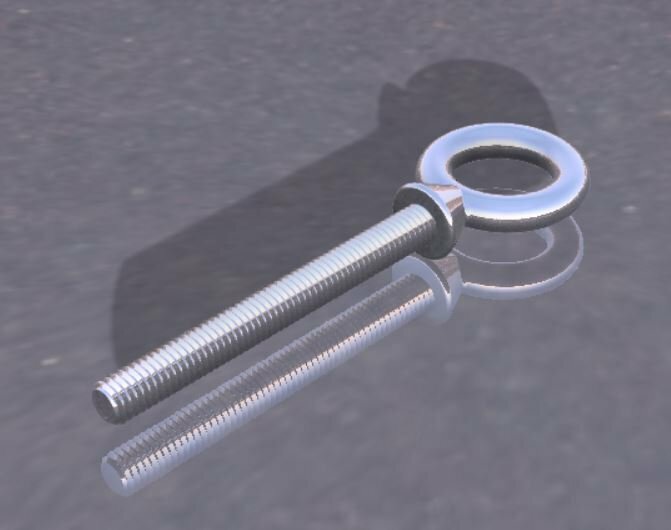

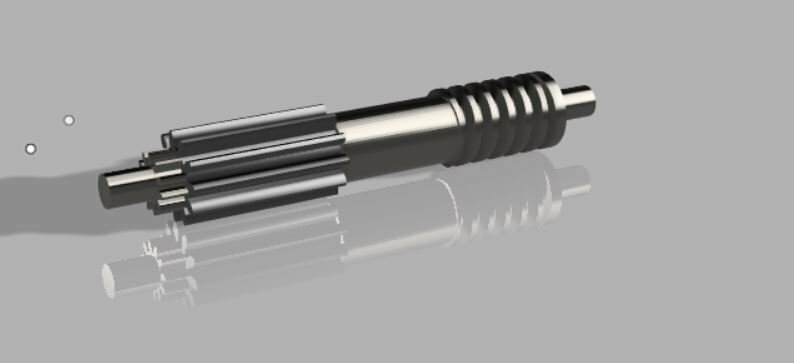

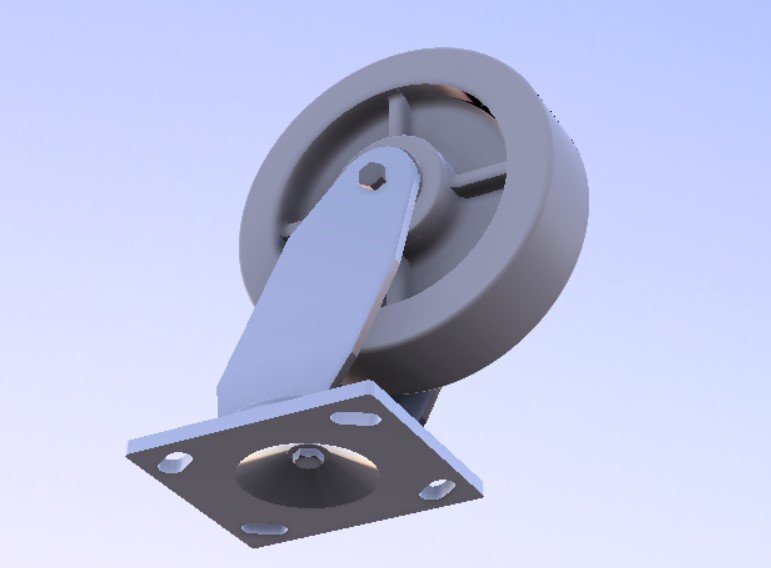

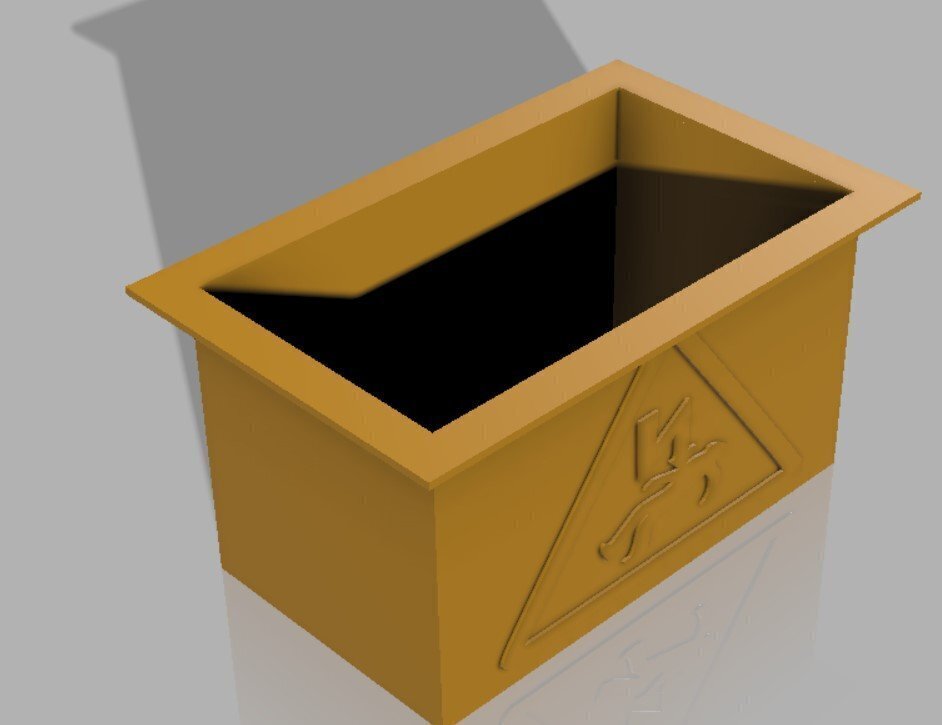

When it comes to certain projects, a computer-aided design, or CAD, can be extremely beneficial. A main advantage to using CAD is the fact that it provides experts with greater accuracy. This is done by replacing manual drafting with electronic design software, such as SketchUp, Fusion 360, or AutoCAD Design Edition. With cad design services, we're not only able to develop our designs, but we can also create three-dimensional prototypes with the help of a 3d printing service. Plus, with metal 3d printing, we can create stronger and more durable prototypes for testing.

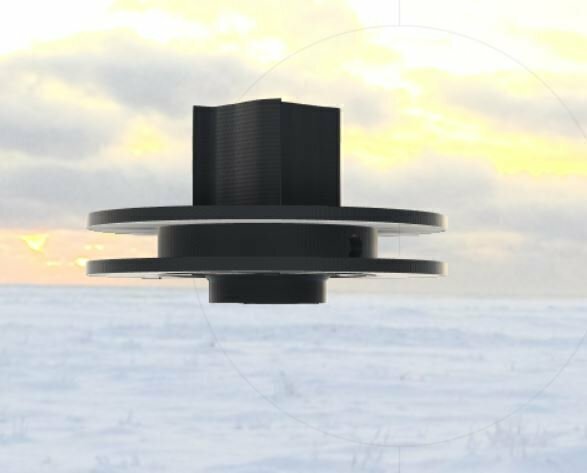

3D printing can help reduce costs and save time by creating prototypes faster and at a lower cost. This is because additive manufacturing technology builds objects by adding material layer by layer, rather than having to carve or remove material to create the desired shape.

Overall, CAD and 3D printing technology can help streamline the product development process, from design to final product. This not only saves time and money, but it can also help create better products.

Frequently Asked Questions

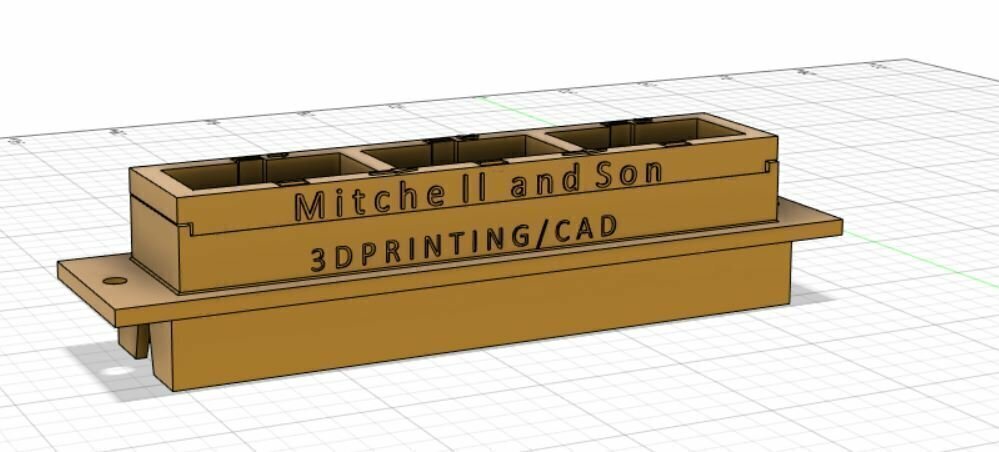

Design and create a 3D model.

starts @ £150.00

Our 3d printing prototype service can help you design and create a 3D model for your next project. Using CAD Design, we'll take an object apart to create the blueprint for your new product or idea.

Business Service

£295.00

Per day

Perfect for small companies

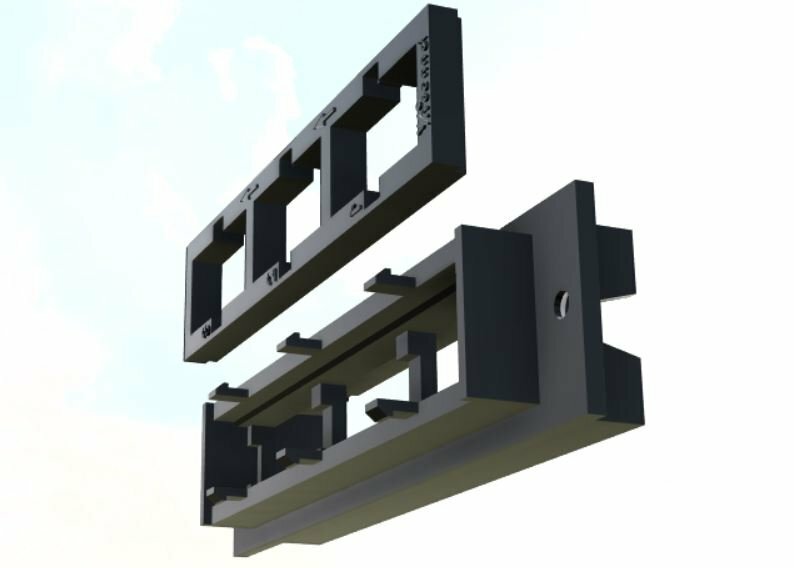

Reverse Engineer upto 5 products (T's & C's) Apply

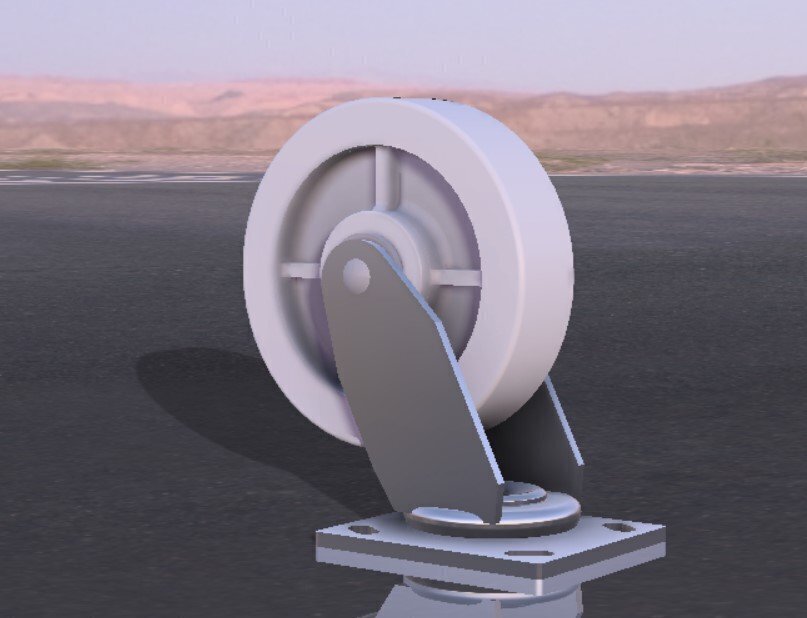

3D Scanning

£760

Per Day

Detailed Scanning and Electronic Archiving of Larger Items ( ie. complete car )

All the services you need,

all in one place.

We offer a wide range of services to meet every type of need.

When CAD first came onto the scene, it was a game-changer for engineers. No longer were they restricted to pencil and paper or relying on manual labor to create prototypes. With this new technology, they could create designs that were accurate to the nth degree and test them virtually before ever moving to a physical model.

It's hard to overstate how transformative this has been for the engineering process. It's now possible to create and iterate on designs much faster, and with greater precision. And as 3D printing technology has become more advanced, it's also become possible to create prototypes directly from CAD files.

This has been a huge boon for companies who are trying to bring new products to market quickly. In the past, the engineering and prototyping process could take months or even years. But with CAD and 3D printing, it's possible to go from concept to final product in a fraction of the time.

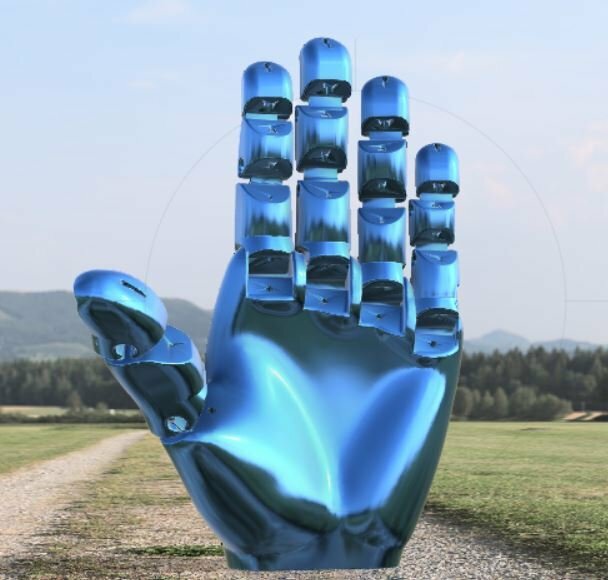

It's also made it possible for engineers to create more complex designs than ever before. And as we continue to push the boundaries of what's possible with CAD and 3D printing, there's no telling what we'll be able to create in the future.

It is amazing how much CAD has changed the engineering and manufacturing process. In the past, engineers would have to create physical prototypes of their products and then test them to see if they worked correctly. This was a time-consuming and expensive process.

With CAD, engineers can now create virtual prototypes of their products. This helps to save on manufacturing costs and ensure that products are designed correctly before they move onto the next stage of production.

In addition, CAD can be used to create 3D models that can be printed using a variety of different methods, including stereolithography (SLA), selective laser sintering (SLS), and fused deposition modeling (FDM).

These models can then be used for testing purposes or to create working prototypes that can be used in the market.

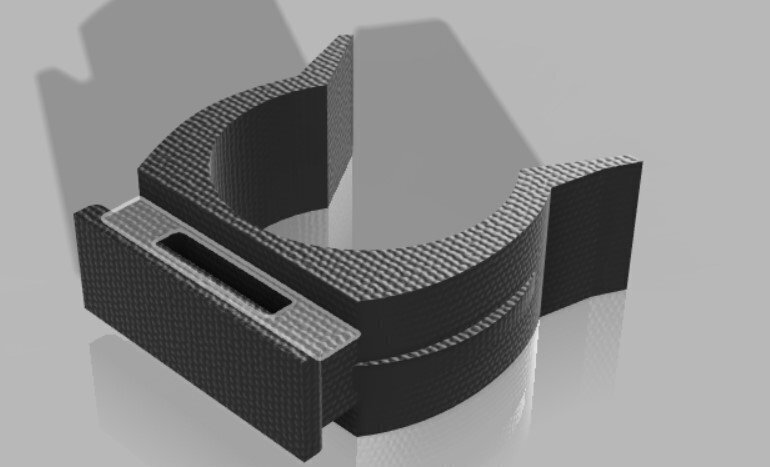

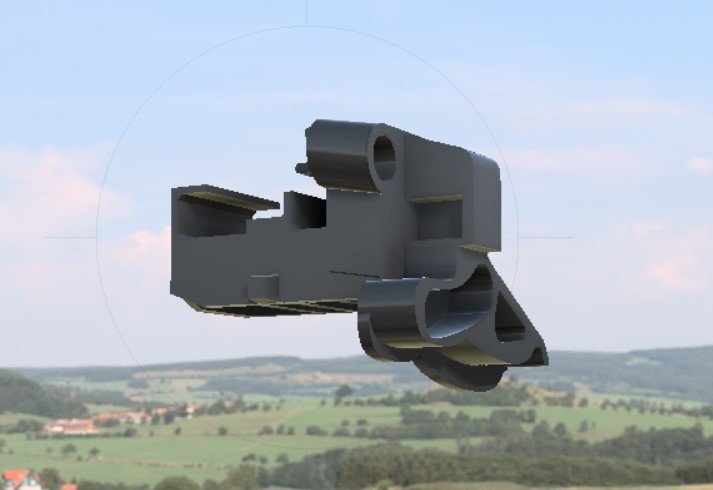

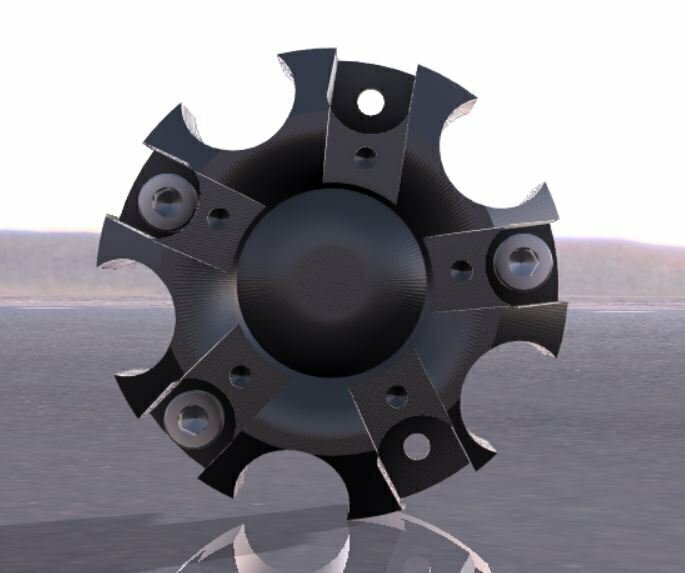

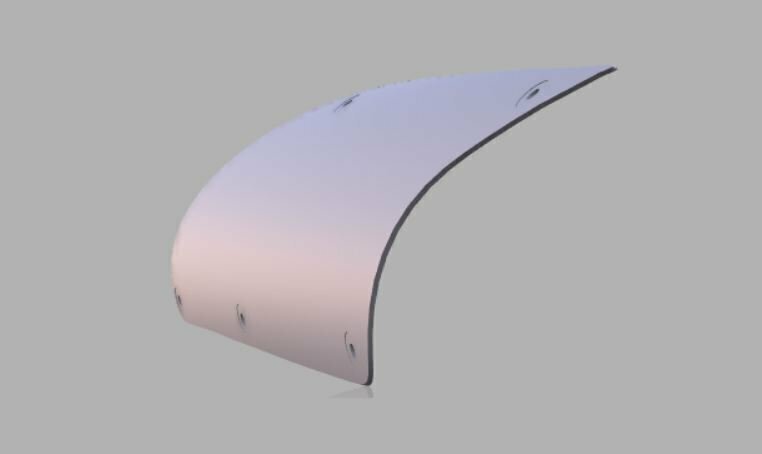

One of the great advantages of reverse engineering is that it allows you to learn from the successes of others. By studying how a product or system was built, you can figure out how to improve upon it or build something similar.

Reverse engineering has been used to develop new products and technologies for centuries. In the early days of the industrial revolution, factories would often reverse engineer products they had imported from other countries in order to learn how to make them themselves.

Today, reverse engineering is commonly used in the software industry. When a new software program is released, it is not uncommon for other companies to reverse engineer it in order to figure out how it works and how they can make their own programs that are compatible with it.

Reverse engineering is also used in the aerospace industry. When a new aircraft is designed, it is often necessary to reverse engineer existing aircraft in order to understand their flight characteristics. This information is then used to design the new aircraft.

Reverse engineering can also be used to improve upon existing products. For example, if you have an old computer that you want to upgrade, you can reverse engineer it to figure out which parts can be replaced with newer, more powerful ones.

Reverse engineering is a powerful tool that can be used to create new products, improve upon existing ones, or simply to learn from the successes of others.