Automotive Repairs and Restoration

Automotive parts fail in annoying ways — clips snap, brackets crack, housings fatigue, and then you find out the part is discontinued. That’s exactly where 3D printing can be a practical fix.

Helps most in Automotive

The big win is when a small plastic part is stopping a bigger repair. If the part is discontinued, back-ordered, or only sold with a full assembly, printing a replacement can save a lot of money and time.

The key is choosing the right material for heat, vibration, and how the part is loaded. That’s why I’ll always ask where it sits and what it has to survive.

- Clips, brackets and small housings

- Interior trim fittings and mounting points

- Legacy parts for classic cars and restorations

How is 3D printing used in automotive industry?

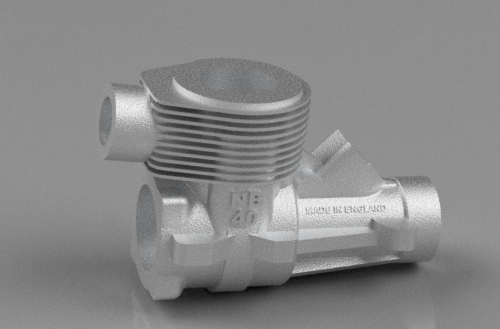

3D printers are no longer a novelty in the automotive world. They are now a standard tool across design studios, factory floors, and even test environments. From early concept work right through to production support, 3D printing is being used to create complex parts, speed up tooling cycles, and solve problems quickly without the delays of traditional manufacturing.

One of the biggest advantages is how fast prototypes and functional parts can be produced. Automotive teams can design a component, print it, test it, adjust it, and reprint it in a fraction of the time it would normally take. This applies across cars, trucks, and motorcycles, and in some cases even full-scale vehicle replicas are produced to check form, fit, and layout before committing to expensive tooling.

Beyond parts themselves, 3D printing plays a major role on the assembly line. Custom jigs, fixtures, and tools can be designed specifically for a single task or station. Instead of holding large inventories or waiting weeks for suppliers, manufacturers can produce exactly what they need, when they need it. That speeds up workflows and reduces both cost and downtime.

Measurement and testing are another area where 3D printing adds real value. Custom gauges, checking fixtures, and test rigs can be printed to verify fit, alignment, and finish. These tools are often unique to a specific component, and printing them makes far more sense than machining or outsourcing one-off items.

Then there’s customization. 3D printing allows manufacturers and specialists to offer tailored solutions that simply weren’t viable before. Things like bespoke badges, trim pieces, interior components, or specialist fittings can be produced without redesigning entire production lines.

Overall, 3D printing is changing how the automotive industry approaches design, testing, and production. It removes barriers, shortens lead times, and makes problem-solving far more practical and cost-effective. It’s not about replacing traditional manufacturing—it’s about using the right tool for the job and doing things smarter from the start.

Cost effectiveness of 3D Printing for the Automotive Industry

3D printing service UK prices have always been a driving force in the automotive industry when it comes to styling and design. In the early days of the automobile, cars were little more than functional boxes on wheels. But as time went on, and cars became more and more commonplace, designers began to experiment with different styles and looks.

The first truly iconic car design came from an unlikely source: the Model T Ford. The simple, boxy design of the Model T was unlike anything else on the road at the time, and it quickly became the most popular car in America.

As cars became more sophisticated, so too did their designs. The 1920s saw a boom in the popularity of so-called "streamlined" designs, which emphasized sleek, aerodynamic shapes. Today, car design is more complex than ever, with designers using computer-aided design (CAD) to create ever-more- intricate and detailed designs.

After the Second World War, car design became more conservative. But in the 1960s, designers began to experiment with more radical looks. The most famous example is the Volkswagen Beetle, which featured a rounded, organic shape that was unlike anything else on the road.

Today, car design is more complex than ever before. Thanks to advances in technology, designers can now create detailed 3D models of their designs. This allows for more efficient prototyping, testing, and production.

3D printing is playing a major role in the car design process. Using industrial 3D printing services, designers can quickly and easily create prototypes of their designs. This helps to speed up the design process and bring new products to market faster.

3D printing has been used to create everything from engine parts to body panels. In the future, it is likely that even more car parts will be 3D printed, making the design process even more efficient. With the help of 3D printing services and scanning technology, UK car designers are able to create stylish, efficient, and innovative designs that are changing the automotive industry.