Why we should Copper electroplate 3D prints

Copper electroplating is a process that involves depositing a layer of copper onto the surface of an object using an electric current.

This technique has become increasingly popular for 3D printed parts, as it offers several benefits.

In this blog post, we will discuss the advantages of copper electroplating and why it is beneficial for both industrial and home use.

Firstly, copper electroplating provides improved mechanical and thermal properties. The electroplated copper layer acts as a barrier between the printed part and the environment, protecting it from corrosion and wear.

It also enhances the thermal conductivity of the part, allowing it to better dissipate heat. This is particularly useful for industrial applications where parts are subjected to harsh environments and high temperatures.

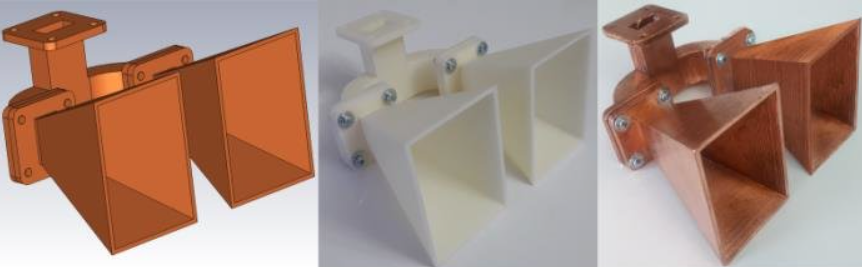

Secondly, copper electroplating enhances the appearance of 3D printed parts. The process creates a uniform and consistent layer of copper, providing a more polished and professional look. This makes it an attractive option for decorative and aesthetic applications, particularly in the home.

Thirdly, copper electroplating improves the electrical conductivity of 3D printed parts. Copper is a highly conductive metal, and the electroplating process creates a thin layer of copper that enhances the conductivity of the printed part.

This is particularly useful for electronic components and devices, allowing for better signal transfer and lower resistance.

Fourthly, copper electroplating improves the durability of 3D printed parts. The layer of copper provides a protective coating that prevents the printed part from being damaged or broken easily.

This is particularly useful for industrial applications where parts are subjected to frequent use and wear and tear.

Fifthly, copper electroplating is a cost-effective way to improve the properties of 3D printed parts. Copper is relatively inexpensive compared to other metals and the electroplating process is efficient and quick.

This makes it an attractive option for both industrial and home use, allowing for the creation of high-quality and durable parts without breaking the bank.

Lastly, copper electroplating is an environmentally friendly option for improving the properties of 3D printed parts. The process does not require the use of hazardous chemicals, making it a safer and more sustainable alternative to other metal plating techniques.

This makes it an ideal option for both industrial and home use, allowing for the creation of high-quality and sustainable parts.

In conclusion, copper electroplating offers several benefits for 3D printed parts, including improved mechanical and thermal properties, enhanced appearance, improved electrical conductivity, increased durability, cost-effectiveness, and environmental friendliness.

These benefits make it an attractive option for both industrial and home use, allowing for the creation of high-quality and durable parts that meet the demands of various applications.