The Power of 3D Printing: Inspiring Innovation Across Industries

Inspiring Innovation Across Industries

Innovation is the driving force behind progress, and in today's fast-paced world, businesses must constantly adapt to remain competitive. One technology that is helping to drive innovation is 3D printing, also known as additive manufacturing.

With its ability to quickly produce complex and customized designs, 3D printing is transforming industries from aerospace to medical to consumer products. In this blog post, we'll explore the power of 3D printing and how it's inspiring innovation across industries.

3D printing has come a long way since its inception in the 1980s. Today, it's a mature technology that's used to produce everything from prototypes to end-use parts.

With advances in materials and printing processes, 3D printing is now a viable option for a wide range of applications.

Additive Manufacturing has revolutionized the way we think about product development. With the ability to quickly produce functional prototypes, businesses can test and refine their designs before moving into production, reducing costs and improving efficiency.

Rapid Prototyping is a key advantage of 3D printing. By rapidly iterating designs, businesses can bring products to market faster than ever before. This is especially important in industries like medical device manufacturing, where time is critical.

Innovation is at the heart of 3D printing. With its ability to produce customized and complex designs, 3D printing is opening up new possibilities for businesses across industries.

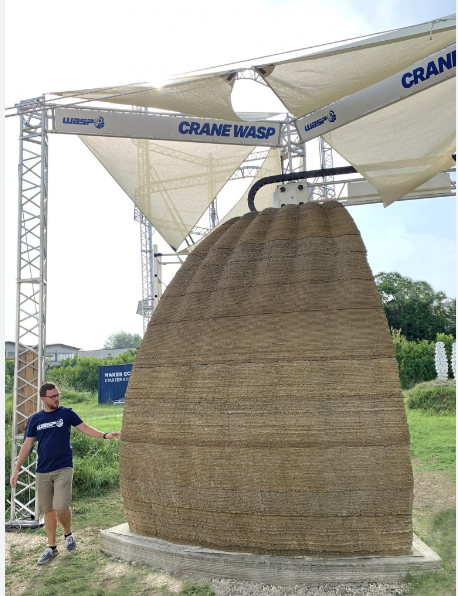

From aerospace to medical to consumer products, 3D printing is transforming the way we think about product design and manufacturing.

Design Thinking is an important part of 3D printing. With the ability to produce highly detailed and complex designs, 3D printing encourages designers to think outside the box and push the boundaries of what's possible.

Product Development has been transformed by 3D printing. By enabling rapid prototyping and iteration, businesses can bring products to market faster and with greater accuracy than ever before.

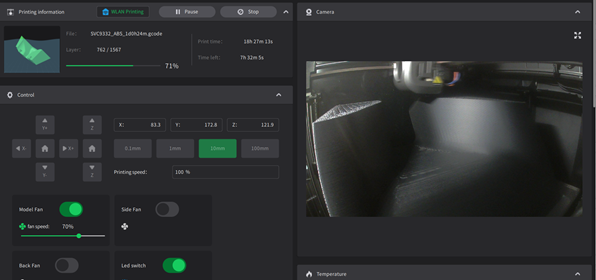

Digital Manufacturing is the future of manufacturing, and 3D printing is leading the way. By using digital models to produce physical objects, 3D printing is revolutionizing the manufacturing process, reducing waste and improving efficiency.

Engineering is an essential component of 3D printing. With its complex materials and printing processes, 3D printing requires skilled engineers to design and optimize products for printing.

ManufacturingTechnology is constantly evolving, and 3D printing is at the forefront of this evolution. With advances in materials and printing processes, 3D printing is becoming more accessible and affordable, opening up new possibilities for businesses across industries.

Innovation is the driving force behind progress, and 3D printing is one of the most exciting technologies in the field of innovation.

With its ability to produce customized and complex designs, 3D printing is inspiring businesses to think differently and push the boundaries of what's possible.

In conclusion, 3D printing is transforming industries from aerospace to medical to consumer products. With its ability to produce customized and complex designs, 3D printing is inspiring innovation and driving progress. As this technology continues to evolve, we can expect to see even more exciting possibilities emerge in the world of manufacturing and product development.