The combination of 3D printing and sustainable practices

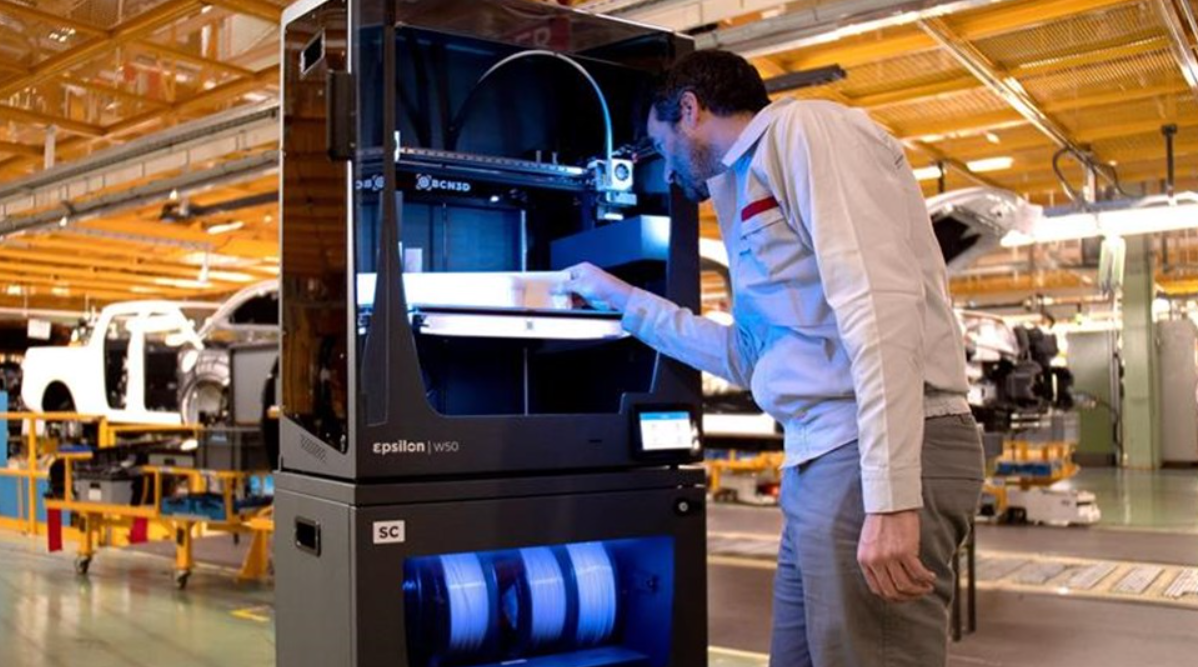

Automotive Industry, exploring the potential of 3D Printing :

In recent years, the automotive industry has been exploring the potential of 3D printing. The technology has been used to create prototypes and even some production parts, with new advancements in materials and printing technologies, it's expected to become an even more important tool in the design and manufacturing of cars.

At the same time, sustainable 3D printing is emerging as a potential solution to concerns about the environmental impact of traditional manufacturing methods. With biodegradable materials and more efficient printing processes, 3D printing could help reduce waste and carbon emissions in manufacturing.

The combination of 3D printing and sustainable practices in the automotive industry is a truly exciting prospect.

3D printing has the potential to revolutionize the way that cars are designed and manufactured, allowing for greater customization and more efficient production processes.

It can also help reduce waste and carbon emissions by reducing the amount of material needed and minimizing the use of harmful chemicals in the production process.

One of the most exciting applications of 3D printing in the automotive industry is in the creation of prototypes.

By using 3D printing, car manufacturers can create highly detailed and accurate prototypes at a fraction of the cost and time required by traditional methods. This allows for faster iterations and a more streamlined design process, ultimately leading to better products and more efficient manufacturing.

Another benefit of 3D printing is the ability to create customized parts. With traditional manufacturing methods, creating unique parts for each car would be prohibitively expensive and time-consuming.

However, with 3D printing, customization becomes much more feasible, allowing for greater flexibility in design and a more personalized customer experience.

In addition to these benefits, sustainable 3D printing has the potential to greatly reduce the environmental impact of the automotive industry.

By using biodegradable materials and minimizing waste, 3D printing can help to mitigate some of the negative effects of traditional manufacturing processes.

This is especially important as concerns about climate change and environmental degradation continue to grow.

Overall, the combination of 3D printing and sustainable practices represents a promising future for the automotive industry.

As technology continues to advance and new materials and processes are developed, we can expect to see even more innovative applications of this technology.

By embracing sustainable 3D printing practices, car manufacturers can help reduce their impact on the environment while also improving their products and processes.

The future of the automotive industry is bright, and 3D printing is sure to play an important role in shaping it.

One of the biggest advantages of 3D printing in the automotive industry is the ability to print parts with complex geometries that would be difficult or impossible to produce using traditional manufacturing methods.

This is particularly important in the design of lightweight components that can improve fuel efficiency and reduce carbon emissions.

With 3D printing, it is possible to create parts with intricate internal structures that are both strong and lightweight, reducing the weight of the vehicle and improving its overall performance.

Sustainable 3D printing is also contributing to the development of new, more environmentally friendly materials.

Biodegradable materials, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), can be used in 3D printing to create parts that are more easily decomposed and recycled than those made from traditional materials.

This reduces the amount of waste generated during the production process and helps to mitigate the environmental impact of the automotive industry.

Another benefit of 3D printing is its ability to produce parts on demand, reducing the need for large inventories and warehousing.

This can significantly reduce the energy and resources required for transportation and storage, further reducing the environmental impact of the manufacturing process.

Additionally, 3D printing allows for rapid prototyping and small-batch production, reducing the time and cost required to bring new products to market.

In the automotive industry, 3D printing is also being used to create tools and fixtures for use in production.

This allows for greater precision and customization in the manufacturing process, reducing the likelihood of errors and improving the quality of the finished product.

Furthermore, by using 3D printing to create these tools and fixtures, manufacturers can reduce the amount of waste generated by traditional manufacturing processes, such as casting and machining.

Finally, 3D printing has the potential to create new opportunities for sustainability in the automotive industry.

For example, 3D printing could be used to produce spare parts on demand, reducing the need for large inventories and the associated energy and resource use.

This would also help to extend the lifespan of vehicles, reducing the number of new vehicles that need to be manufactured and further reducing the environmental impact of the industry.

In conclusion, 3D printing and sustainable practices are shaping the future of the automotive industry.

By embracing this technology and using it to improve the design and manufacturing processes, manufacturers can reduce their environmental impact while also improving the quality of their products.

With new advancements in materials and printing technologies, we can expect to see even more innovative applications of 3D printing in the automotive industry in the years to come.

By continuing to explore the potential of this technology, we can help to create a more sustainable and efficient automotive industry for generations to come.