Rapid Prototyping: The Revolution of 3D Printing

Introduction

In today's fast-paced world, the race to market is more intense than ever. Companies and individuals alike are in a perpetual hunt for methods to accelerate the product development cycle. Enter rapid prototyping, a collective term for techniques designed to swiftly fabricate scale models or functional parts.

Among these techniques, 3D printing has emerged as a game-changer, offering a unique blend of versatility, speed, and cost-effectiveness.

In this article, we'll delve deep into the various facets of rapid prototyping with a particular focus on 3D printing technologies.

What is Rapid Prototyping?

Rapid prototyping is a modern manufacturing process that allows for the quick creation of physical prototypes directly from digital designs. Traditional methods of prototyping, such as milling and molding, can be labor-intensive and time-consuming.

Rapid prototyping, however, leverages cutting-edge technologies to simplify and expedite this process. Because time is money in the business world, the advent of rapid prototyping has been a game-changer for multiple industries.

A Brief History of Rapid Prototyping

The roots of rapid prototyping can be traced back to the late 1980s when 3D Systems introduced the first commercial 3D printing system. This was a watershed moment for both prototyping and manufacturing as a whole.

Over the years, the technology evolved, incorporating new materials and becoming more accessible to small businesses and even individuals.

With this democratization of technology, we've seen a boom in innovation and an accelerated path from idea to market for countless products.

Types of Rapid Prototyping Methods

Rapid prototyping is a term that encompasses a range of techniques. While 3D printing stands out as the most prominent, it's essential to note other methods like selective laser sintering (SLS) and stereolithography (SLA).

Each method has its unique advantages and limitations, depending on the materials used, the complexity of the design, and the intended application.

However, for the purpose of this article, we'll be focusing primarily on 3D printing technologies.

Why 3D Printing Stands Out

When it comes to rapid prototyping, 3D printing has some significant advantages over other methods. The first is its unparalleled versatility; 3D printers can produce intricate designs that would be incredibly difficult, if not impossible, to create using traditional techniques.

Second, 3D printing is highly scalable. Whether you need a single prototype or a short production run, the process remains largely the same.

Lastly, the technology is becoming increasingly affordable, making it accessible to startups and individual entrepreneurs.

Understanding 3D Printing Technologies

Fused Deposition Modeling (FDM)

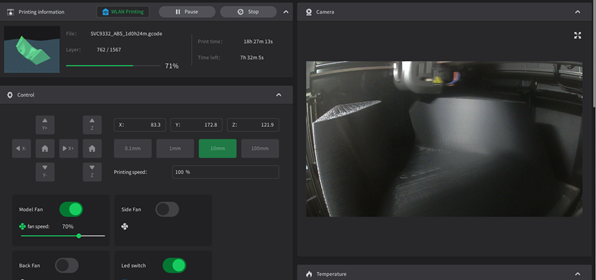

FDM is perhaps the most commonly used 3D printing technology today. It involves extruding thermoplastic materials layer by layer to create an object.

This method is well-suited for prototyping, educational purposes, and low-volume production. While it may not offer the highest resolution, it compensates with material variety and general affordability.

Stereolithography (SLA)

SLA is a 3D printing technology that utilizes a laser to cure liquid resin into solid form.

Known for its high accuracy and excellent surface finish, SLA is often used in industries like healthcare and automotive design. However, the materials can be expensive, and the process may require additional post-processing steps.

Selective Laser Sintering (SLS)

SLS employs a laser to sinter powdered material into a solid structure. While less common than FDM or SLA, SLS is valued for its ability to create complex, durable parts without the need for supports. Industries such as aerospace and engineering often prefer SLS for its material properties and structural integrity.

Practical Applications of 3D Printing in Rapid Prototyping

Product Design and Development

In the realm of product design, 3D printing allows designers to transform their digital sketches into tangible prototypes rapidly. This immediate physical representation enables easy evaluation, be it for aesthetic appeal, ergonomics, or functionality.

Medical Applications

In healthcare, 3D printed prototypes are invaluable for planning surgeries or creating customized implants. The quick turnaround time is particularly beneficial in urgent medical situations.

Aerospace and Automotive Industries

Both the aerospace and automotive sectors have embraced 3D printing for rapid prototyping due to the method's ability to create parts that are both lightweight and highly durable. Whether it's for testing aerodynamic features or experimenting with new materials, 3D printing offers a swift and effective solution.

The Future of Rapid Prototyping and 3D Printing

As we move forward, we can expect rapid prototyping technologies, particularly 3D printing, to become even more integral to various industries.

Advancements in material science, AI-driven design algorithms, and automation will likely make these technologies faster, cheaper, and more versatile.

Conclusion

In summary, rapid prototyping has drastically shortened the time from concept to physical product, acting as a catalyst for innovation across various fields. Among the methods used in rapid prototyping, 3D printing stands as a versatile and increasingly accessible technology, promising to revolutionize the future of manufacturing and design further.

While this article offers a detailed look at rapid prototyping and 3D printing, it's essential to remember that technology is ever-evolving.

To stay ahead, one must be willing to adapt and integrate these emerging technologies continually.

Therefore, the journey of understanding and utilizing rapid prototyping and 3D printing for your projects is an ongoing process, and a rather exhilarating one at that.