Is 3D Printing a sustainable manufacturing method?

Sustainable 3D Printing Technology, Methods, Waste Reduction, and Materials

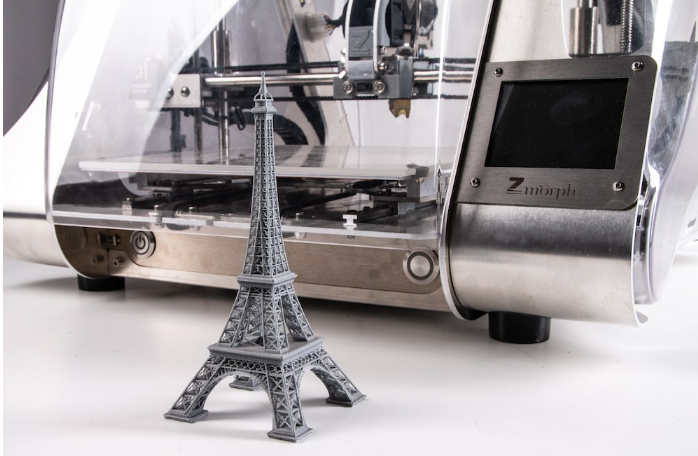

3D printing has revolutionized the way we manufacture products, making it possible to create complex shapes and geometries that were previously impossible to produce with traditional manufacturing methods.

However, 3D printing has also created new environmental challenges, such as the production of plastic waste and energy consumption. To address these challenges, sustainable 3D printing technology, methods, waste reduction, and materials have emerged.

In this blog post, we will discuss the latest developments in sustainable 3D printing technology, methods, waste reduction, and materials.

Sustainable 3D Printing Technology

Sustainable 3D printing technology focuses on reducing energy consumption and waste production during the 3D printing process. One approach is to use 3D printers that consume less energy, such as those that use LED curing or infrared heating technologies.

These printers can reduce energy consumption by up to 90% compared to traditional 3D printers that use high-powered lasers or heaters.

Another approach is to use 3D printing software that optimizes the printing process for energy efficiency.

For example, the software can automatically adjust the printing speed and temperature based on the complexity of the design and the materials being used, which can reduce energy consumption by up to 30%.

Sustainable 3D Printing Methods

Sustainable 3D printing methods focus on reducing waste production during the printing process.

One approach is to use 3D printers that can print with recycled materials. These printers use recycled plastics, metals, and other materials to create new objects. This approach not only reduces waste but also reduces the need for new raw materials.

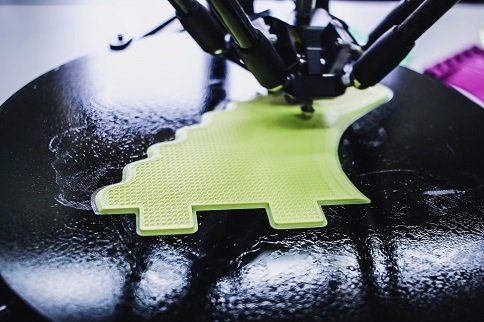

Another approach is to use 3D printing methods that produce less waste.

For example, some printers use a process called fused filament fabrication, which produces less waste than traditional printing methods.

This method involves melting plastic filaments and extruding them through a nozzle to create the object. Any excess plastic can be reused in the printing process, reducing waste.

Sustainable 3D Printing Waste Reduction

Sustainable 3D printing waste reduction focuses on reducing waste produced after the printing process. One approach is to recycle the plastic waste produced during the printing process.

This can be done by shredding the waste and melting it down to create new filament for 3D printing.

Another approach is to use biodegradable materials for 3D printing.

These materials break down naturally over time and do not contribute to plastic waste in the environment.

Some examples of biodegradable materials for 3D printing include polylactic acid (PLA), which is made from cornstarch or sugarcane, and cellulose-based materials.

Sustainable 3D Printing Materials

Sustainable 3D printing materials focus on reducing the environmental impact of 3D printing materials. One approach is to use bio-based materials that are made from renewable resources such as plants or biomass.

These materials have a lower carbon footprint and are biodegradable, making them a more sustainable option.

Another approach is to use recycled materials for 3D printing.

These materials can be made from post-consumer waste or industrial waste and can be used to create new objects.

Recycled materials have a lower environmental impact than new materials because they reduce the need for new raw materials.

Conclusion

Sustainable 3D printing technology, methods, waste reduction, and materials are important developments that address the environmental challenges of 3D printing.

By reducing energy consumption, waste production, and the environmental impact of 3D printing materials, these developments make 3D printing a more sustainable and environmentally friendly manufacturing method.

As the technology and materials continue to evolve, we can expect to see more sustainable 3D printing solutions in the future.