How big is Big when it comes to 3D Printing?

How the Introduction of Larger 3D Printers & 3D Scanning Technology is Revolutionizing Mass Customization

The introduction of larger 3D printers and 3D scanning technology has opened up a world of possibilities, allowing businesses to revolutionize the way they produce and customize products.

This technology is changing the way that companies think about mass production, allowing them to produce more complex products quickly and efficiently. With the ability to scan, design, and print products in a matter of hours, businesses are now able to provide customers with products that are tailored specifically to their individual needs.

Not only does this technology provide businesses with an unprecedented level of flexibility, but it also allows them to stay competitive in today's dynamic market.

By utilizing larger 3D printers and 3D scanning technology, businesses are able to create products that are unique and tailored to the customer’s desired specifications.

This technology has revolutionized the concept of mass customization, allowing businesses to meet the ever-changing needs of the modern consumer.

Benefits of Large 3D Printers & 3D Scanning Technology

The introduction of larger 3D printers and 3D scanning technology has allowed businesses to make significant advancements in the field of mass customization.

By adding 3D scanning and 3D printing capabilities to existing production lines, manufacturers are able to quickly design and produce custom products to satisfy the needs of specific customers.

These products are also made with specific materials, allowing manufacturers to create products that are tailored to specific customer needs. Furthermore, the ability to create custom products on-demand means that businesses are now able to meet the ever-changing needs of their customers.

This means that customers can benefit from a much more personalized experience when purchasing products that are tailored to their exact specifications.

As a result, businesses can significantly increase their profits by providing customers with customized products that meet their specific needs.

Development of New Materials

As 3D printing technology has evolved, so too has its ability to work with new materials. This allows a much wider variety of materials to be used in 3D printing, which in turn allows manufacturers to create custom products that were not possible with older 3D printers.

By adding 3D scanning and 3D printing capabilities to existing production lines, larger 3D printers are now able to create products that were previously impossible.

For example, a 3D printer is now able to create a custom, anti-counterfeit material that is nearly impossible to replicate.

Because of this, manufacturers are able to create a variety of new products, allowing them to meet the ever-changing needs of their customers.

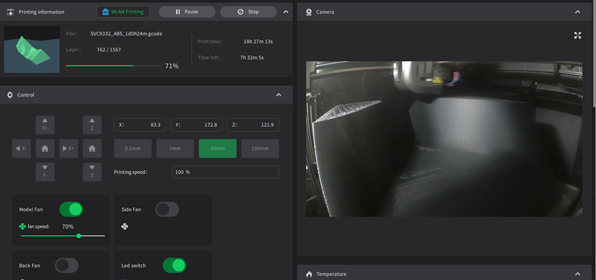

Increased Speed and Efficiency

As 3D printing technology has evolved, so too has its ability to work with different materials. This allows a much wider variety of materials to be used in 3D printing, which in turn allows manufacturers to create custom products that were not possible with older 3D printers.

With the ability to create products from different materials, manufacturers are able to produce custom-made goods at a much faster rate. This is particularly beneficial in the manufacturing of complex products, allowing them to produce high-end goods at a much lower production cost.

Furthermore, larger 3D printers are also able to produce goods at a much higher quality than smaller 3D printers, allowing them to create products that are tailored to the customer’s desired specifications.

By utilizing larger 3D printers and 3D scanning technology, businesses are able to produce custom goods of a much higher quality, allowing them to meet the ever-changing needs of their customers.

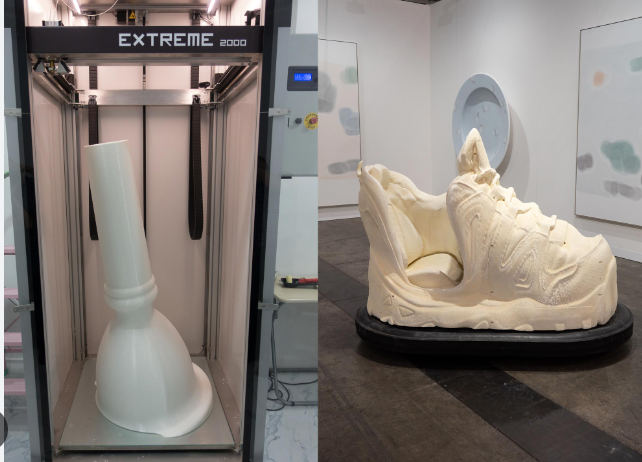

Larger Printing Volumes

One of the most significant advantages of utilizing a larger 3D printer and 3D scanning technology is the ability to print larger quantities of goods. This has been a significant problem for many businesses, which struggle to find a way to mass-produce items that are tailored to specific customer needs.

While it may be possible for smaller 3D printers to produce small quantities of goods, larger 3D printers are able to produce goods at a much higher volume.

This allows businesses to produce more goods at once, significantly reducing their production cost.

As a result, businesses are able to produce custom goods tailored to the specific needs of customers, significantly increasing their profits from each sale.

Multi-Material Printing

Another significant advantage of utilizing larger 3D printers and 3D scanning technology is the ability to print multi-material goods. This was previously only possible with highly complex, high-end printing equipment.

However, the introduction of larger 3D printers makes this process much more accessible, allowing manufacturers to create custom goods that were not previously possible. By printing different materials on a single 3D printer, manufacturers are able to create custom goods that are tailored to the specific needs of their customers.

This is particularly beneficial when designing products that are highly complex or require a variety of materials. For example, designers can create a bowl that requires a number of different materials and can be printed on a single 3D printer.

This allows customers to customize the bowl to their exact specifications, significantly increasing the chances that the customer will purchase the product.

Applications of Large 3D Printers & 3D Scanning Technology

The introduction of 3D printing technology has had an enormous impact on the manufacturing industry, significantly changing the way that products are designed and produced.

This has allowed businesses to significantly increase their profits by providing customers with customized products that meet their specific needs. As a result, manufacturers are now able to create custom goods that are tailored to the specific needs of the customer, significantly increasing their chances of selling the product.

Additionally, the introduction of larger 3D printers and 3D scanning technology has allowed manufacturers to create custom goods with different materials, significantly increasing their profits from each sale.

Challenges of Large 3D Printers & 3D Scanning Technology

While the introduction of larger 3D printers and 3D scanning technology has had a significant impact on the manufacturing industry, it has also been accompanied by a number of challenges.

Many of the risks associated with 3D printing and 3D scanning technology were not fully understood until recently. This means that manufacturers who choose to utilize these technologies are often forced to take risks with their finances and reputations.

This is particularly concerning given the highly sensitive nature of some of these technologies. For example, the printing of guns, drugs, and other dangerous items is a concern that many manufacturers must face.

However, without the ability to utilize large 3D printers and 3D scanning technology, manufacturers may be forced to work with less-advanced equipment that is less safe for the environment.

Examples of Companies Using Large 3D Printers & 3D Scanning Technology

One of the most significant benefits of utilizing large 3D printers and 3D scanning technology is the ability to print custom-made goods. This allows businesses to produce custom-made goods that are tailored to the specific needs of the customer.

While the printing of custom goods was previously only possible with highly complex, high-end equipment, this technology is now available to all manufacturers.

While the printing of customized products is beneficial for all businesses, it is particularly beneficial for large manufacturers that are able to print complex, custom products.

For example, General Electric is using its new 3D printer to produce customized jet engines that can be printed at a much lower production cost than traditional manufacturing methods.

This has allowed GE to significantly reduce its production cost, significantly increasing its profits from each sale.

Conclusion

The introduction of larger 3D printers and 3D scanning technology has opened up a world of possibilities, allowing businesses to revolutionize the way that they produce and customize products.

This technology is changing the way that companies think about mass production, allowing them to produce more complex products quickly and efficiently.

With the ability to scan, design, and print products in a matter of hours, businesses are now able to provide customers with products that are tailored specifically to their individual needs.

Not only does this technology provide businesses with an unprecedented level of flexibility, but it also allows them to stay competitive in today’s dynamic market.

By utilizing larger 3D printers and 3D scanning technology, businesses are able to create products that are more cost-effective, efficient, and unique.

The introduction of this technology has allowed companies like GE to significantly reduce their production costs and increase their profits.