Guide to 3D Printing Services for a Replacement Part

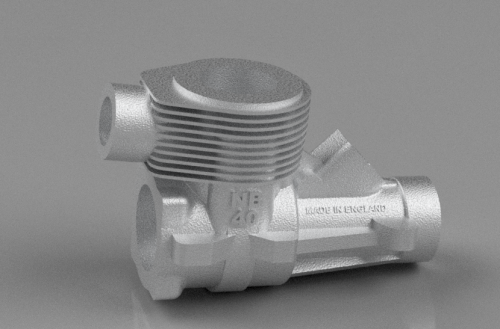

Producing a Single Replacement Part

In today's fast-paced world, innovation reigns supreme. Businesses and individuals alike are constantly seeking ways to improve efficiency, reduce costs, and minimize downtime. One remarkable technology that has been a game-changer in this regard is 3D printing.

While it has revolutionized industries like aerospace and healthcare, it has also made a significant impact on the world of replacement parts. In this comprehensive guide, we explore the fascinating realm of 3D printing services for replacement part and how they can transform the way we maintain and repair our machinery.

Understanding the Power of 3D Printing

3D printing, also known as additive manufacturing, is a groundbreaking process that enables the creation of three-dimensional objects from a digital file. This technology has evolved significantly over the years, making it possible to produce intricate and highly precise parts. It all begins with a 3D model, typically created using Computer-Aided Design (CAD) software.

The Benefits of 3D Printing for a Replacement Part

1. Cost-Efficiency: Revolutionizing Your Budget

When it comes to cost-efficiency, 3D printing stands as a true game-changer. Traditional manufacturing methods often involve substantial setup costs and long lead times. But with 3D printing, the financial landscape undergoes a significant transformation.

Reducing Inventory Costs: Conventional manufacturing often necessitates maintaining large inventories of replacement parts to ensure they are readily available when needed. This ties up capital and storage space. However, 3D printing allows for on-demand production, meaning you don't have to stockpile replacement parts. You simply print them as required, significantly reducing inventory-related expenses.

Minimizing Waste: Traditional manufacturing generates substantial waste during the production process, including leftover material that can't be reused. 3D printing, in contrast, is an additive manufacturing process, where material is deposited layer by layer to create the part. This approach drastically reduces waste, contributing to cost savings and aligning with modern sustainability goals.

Customization Without Added Costs: In the traditional manufacturing world, customization often comes at a premium. If you need a specialized replacement part, it can be expensive due to changes in tooling and processes. 3D printing eliminates these hurdles, allowing each replacement part to be customized without additional costs. This not only saves money but also opens the door to highly specialized components.

2. Customization: Tailoring Perfection

3D printing takes customization to an entirely new level. Every replacement part can be meticulously tailored to meet specific requirements without incurring extra expenses.

Meeting Unique Needs: In situations where off-the-shelf replacement parts don't quite fit the bill, 3D printing offers a solution. Whether it's an odd-shaped bracket, a one-of-a-kind hinge, or a specialized mechanical component, 3D printing excels at crafting parts that precisely match your unique needs.

Optimizing for Functionality: Traditional manufacturing might force you to compromise on design and functionality to fit within standard production methods. 3D printing knows no such bounds. If you require a replacement part to perform a specific function or fit into a tight space, 3D printing can achieve it with precision.

3. Speed: Minimizing Downtime, Maximizing Productivity

The speed at which 3D printing operates is a remarkable advantage. In the world of manufacturing, time is money, and 3D printing offers a significant time-saving advantage.

Reduced Downtime: When machinery or equipment requires a replacement part, every minute of downtime impacts productivity and profitability. Traditional manufacturing methods often come with long lead times, meaning your equipment might be out of commission for an extended period. 3D printing, on the other hand, is swift. Replacement parts can be printed and installed in a fraction of the time, minimizing downtime and maximizing productivity.

On-Demand Production: The concept of on-demand production is at the heart of 3D printing. You no longer need to anticipate your part needs and order them in advance. With 3D printing, you print the replacement part precisely when you need it, ensuring your operations keep running smoothly.

4. Complex Geometries: Unlocking Design Possibilities

The ability to produce complex geometries is a distinctive feature of 3D printing. This opens the door to limitless design possibilities, something traditional manufacturing methods often struggle to achieve.

Intricate and Lightweight Structures: In traditional manufacturing, intricate, lightweight structures can be challenging to produce. However, 3D printing excels at this, making it possible to create components with internal cavities, lattices, and organic shapes that were once unattainable. These designs can result in stronger, more efficient parts.

Reduced Assembly Needs: Complex geometries often mean that several parts can be consolidated into a single 3D-printed component. This not only simplifies the assembly process but also reduces the risk of components failing at assembly points.

5. Sustainability: A Green Revolution in Manufacturing

In a world where environmental responsibility is a top priority, 3D printing shines as a more sustainable option for manufacturing replacement parts.

Reduced Waste: The conventional subtractive manufacturing process involves removing material to shape a part, which generates significant waste. In contrast, 3D printing is an additive process where material is deposited layer by layer. This significantly reduces waste and aligns with the sustainability goals of reducing environmental impact

The Materials in 3D Printing

1. Plastics: The Versatility of PLA and ABS

When it comes to 3D printing, plastics are a popular choice due to their versatility and widespread availability. Two standout materials in this category are Polylactic Acid (PLA) and Acrylonitrile Butadiene Styrene (ABS).

PLA (Polylactic Acid): PLA is renowned for its ease of use, making it an excellent material for both beginners and experienced 3D printing enthusiasts. It's derived from renewable resources like cornstarch and sugarcane, rendering it an environmentally friendly option. PLA boasts a low melting point, making it compatible with a wide range of 3D printers. Its print quality is outstanding, with minimal warping or distortion during the printing process. PLA is an ideal choice for producing prototypes, intricate models, and consumer products. However, it's worth noting that PLA may not withstand high temperatures and is less durable than some other materials.

ABS (Acrylonitrile Butadiene Styrene): ABS is another commonly used plastic in 3D printing. It's renowned for its durability and impact resistance, making it suitable for functional parts that require robustness. ABS can endure higher temperatures compared to PLA, which makes it a preferred choice for automotive components and electronic enclosures. However, it's essential to note that ABS emits fumes during the printing process, requiring adequate ventilation. Additionally, ABS is more prone to warping and can be challenging to print for beginners. To mitigate these issues, printers with heated beds are often used for ABS printing.

2. Metals: The Strength and Durability of Aluminum, Stainless Steel, and Titanium

In industrial applications, where strength and durability are paramount, metals take center stage in 3D printing. Aluminum, stainless steel, and titanium are the standout materials in this category, each with its unique properties.

Aluminum: Aluminum is well-regarded for its lightweight yet robust nature. It's an ideal choice for parts where weight reduction is critical without compromising strength. The aerospace industry frequently employs aluminum for creating components such as aircraft frames and engine parts. Aluminum 3D-printed parts are not only strong but also corrosion-resistant, making them suitable for outdoor applications.

Stainless Steel: Stainless steel is a go-to material when exceptional resistance to corrosion and high temperatures is required. It's used extensively in industries like oil and gas, where parts must withstand harsh environmental conditions. Stainless steel's remarkable durability and ability to maintain its structural integrity in extreme situations make it a sought-after choice for critical components.

Titanium: Titanium is the heavyweight champion of the metal materials. It's renowned for its exceptional strength-to-weight ratio, making it indispensable in aerospace and medical applications. Titanium 3D-printed parts are biocompatible, making them ideal for medical implants. The aerospace industry harnesses titanium's extraordinary strength and resistance to extreme temperatures in crafting components for spacecraft and aircraft.

3. Ceramics: The Heat-Resistant and Insulating Properties of Alumina and Zirconia

For specialized applications that demand high-temperature resistance and electrical insulation, ceramics come into play. Alumina and zirconia are two ceramic materials that have found their place in 3D printing.

Alumina: Alumina, also known as aluminum oxide, is highly regarded for its exceptional electrical insulation properties. It can withstand extreme temperatures, making it an ideal material for applications such as electrical insulators and components in high-temperature environments. Alumina's electrical insulating properties make it invaluable in the electronics industry, where it is used for producing insulating substrates and circuit components.

Zirconia: Zirconia, or zirconium dioxide, offers a unique combination of high-temperature resistance, mechanical strength, and biocompatibility. This makes it a preferred material for dental implants and medical devices. Zirconia's resistance to wear and corrosion, along with its remarkable strength, ensures the longevity and reliability of the parts it produces.

Plastics, metals, and ceramics each bring their own strengths and characteristics to the world of 3D printing. The choice of material depends on the specific requirements of the replacement part, be it in terms of strength, temperature resistance, or electrical properties. Understanding these material options allows for informed decision-making when embarking on a 3D printing project, ensuring the production of parts that meet the highest standards of quality and performance.

The Process of 3D Printing a Replacement Part

The process of 3D printing replacement parts involves several crucial steps:

1. Design: The Foundation of 3D Printing Precision

At the heart of 3D printing for replacement parts lies the crucial stage of design. It's here that the entire process takes shape. Design starts with the creation of a 3D model using advanced Computer-Aided Design (CAD) software. This digital blueprint is not a mere sketch but a highly detailed, three-dimensional representation of the replacement part.

A notable aspect of this design phase is the level of precision that can be achieved. With CAD software, every nook, cranny, and curve of the replacement part is meticulously captured, ensuring that the final product matches the original in every detail. This level of precision is a game-changer, especially for industries that rely on highly specialized components, where a single millimeter can make a world of difference.

When we talk about 3D printing design, it's not limited to simple geometric shapes. The software can handle the intricacies of complex structures with ease, making it versatile for a wide range of applications. The design phase sets the stage for the entire 3D printing process, ensuring that the resulting replacement part meets the exacting standards of quality and accuracy.

2. Slicing: Breaking Down Complexity into Layers

Once the 3D model is perfected, the next step in the 3D printing process is slicing. This isn't a culinary term but a crucial step in translating the digital model into a physical object. Slicing software takes the highly detailed 3D model and breaks it down into thousands of ultra-thin horizontal layers.

The significance of this slicing process cannot be overstated. Each layer is like a virtual "slice" of the final replacement part. These slices are so thin that they might measure just a fraction of a millimeter in thickness. The precision here is remarkable, akin to cutting a piece of paper into hair-thin strips.

Why is this slicing process so critical? Because it guides the 3D printer throughout the manufacturing process. The printer follows these digital slices layer by layer, adding material accordingly. The more precise and intricate the slicing, the more accurate the final product. This level of detail is vital for producing complex geometries and custom replacement parts.

3. Printing: Layer by Layer, Precision Unfolds

The heart of 3D printing, as the name suggests, is the actual printing process. It's here that the digital design and meticulously sliced layers come to life. The 3D printer takes these digital instructions and begins the additive manufacturing journey.

The magic lies in the layer-by-layer approach. The 3D printer starts with the first slice, typically at the base, and begins adding material. This might be in the form of plastics, metals, ceramics, or other materials, depending on the specific requirements. The printer then moves on to the next layer, adding material precisely where needed to match the digital model.

This incremental, additive process continues until the entire replacement part is complete. What's truly remarkable is the precision and consistency that 3D printing offers. Every layer is placed with meticulous accuracy, resulting in a final product that adheres to the original design with astounding detail.

4. Post-Processing: Perfecting the Final Product

Once the 3D printing is complete, we enter the post-processing phase. While the printing process is highly accurate, some replacement parts may require additional steps to meet specific quality and functional standards.

Post-processing can involve various activities such as cleaning, sanding, or smoothing the surface. This is particularly important when the replacement part needs a polished finish or when there are specific tolerances to be met. It's the equivalent of fine-tuning a musical instrument to ensure every note is pitch-perfect.

In some cases, post-processing may also include painting or coating to provide additional protection or aesthetic enhancement. These final touches ensure that the replacement part not only meets functional requirements but also presents itself with a professional and appealing appearance.

The process of 3D printing replacement parts is a well-orchestrated symphony of design precision, slicing intricacy, layer-by-layer printing, and meticulous post-processing. It's a testament to human ingenuity and technology's ability to craft intricate, custom, and highly accurate replacement parts that have the potential to transform industries and redefine the way we approach maintenance and repair.

Applications of 3D Printing in Various Industries

1. Automotive: Revolutionizing Vehicle Manufacturing

In the automotive industry, 3D printing is not merely a novelty but a transformative force. The technology has revolutionized the way cars are built, impacting everything from vehicle design to manufacturing processes.

Customized Engine Components: 3D printing has made it possible to manufacture highly customized engine components, including intricate geometries that were previously challenging to achieve. This means that automakers can optimize the performance of their engines and create unique parts tailored to specific vehicle models.

Lightweight Structures: Weight reduction is a key goal in automotive design to improve fuel efficiency. 3D printing allows for the creation of lightweight but strong structures, making vehicles more energy-efficient without compromising safety.

Prototyping and Rapid Iteration: Automotive companies use 3D printing extensively for prototyping and rapid iteration. Designers and engineers can quickly produce prototypes of new vehicle models, test different features, and make adjustments in a matter of days rather than weeks or months.

Customized Interiors: Beyond the mechanical aspects, 3D printing is used to create customized interior elements, from dashboard panels to unique seat designs. This personalization adds a touch of luxury and uniqueness to vehicles.

2. Medical: Precision and Personalization in Healthcare

In the medical field, 3D printing has brought about a revolution in patient care and the production of medical devices. It is transforming the way medical professionals approach treatment and rehabilitation.

Patient-Specific Implants: 3D printing allows for the creation of patient-specific implants. Surgeons can now design implants tailored to an individual's unique anatomy, improving the success rate of surgeries and reducing recovery time.

Prosthetics: The creation of prosthetic limbs has been significantly enhanced by 3D printing. These prosthetics can be customized to fit a patient's specific needs and preferences, providing a higher level of comfort and functionality.

Surgical Tools: Surgical instruments and tools can be 3D printed with intricate designs that are difficult to achieve using traditional manufacturing methods. This enhances precision and minimizes trauma during surgical procedures.

Medical Models: 3D printing is used to create anatomical models for surgical planning and medical education. These models allow surgeons to practice complex procedures and enhance their understanding of patient-specific cases.

3. Aerospace: Elevating Aircraft and Spacecraft Design

The aerospace industry has embraced 3D printing to push the boundaries of what is possible in aircraft and spacecraft design. This technology is instrumental in achieving lightweight, high-performance components.

Lightweight Structural Components: Weight is a critical factor in aerospace design. 3D printing enables the creation of lightweight yet structurally sound components, such as aircraft frames and rocket parts. This reduces fuel consumption and enhances flight efficiency.

Complex Engine Parts: Aerospace companies use 3D printing to produce intricate engine components that optimize performance and fuel efficiency. These components can withstand extreme conditions, making them ideal for space exploration.

Rapid Prototyping: The ability to rapidly prototype and test new designs is invaluable in aerospace. 3D printing accelerates the design iteration process, helping engineers refine their ideas and improve performance.

Customized Satellites: Small, customized satellites are on the rise, and 3D printing plays a key role in their production. These satellites can be tailored for specific missions and launched more cost-effectively.

4. Consumer Electronics: Tailored Technology

In the world of consumer electronics, 3D printing is changing the way devices are manufactured. From custom casings to intricate internal components, this technology is unlocking new possibilities.

Custom Device Casings: 3D printing enables consumers to personalize the appearance of their devices. Smartphone cases, laptop shells, and gaming console exteriors can be uniquely designed and printed.

Internal Component Optimization: Manufacturers use 3D printing to produce complex internal components with enhanced performance. This includes intricate cooling systems, specialized connectors, and customized circuitry.

Prototyping and Concept Development: In the fast-paced world of consumer electronics, quick prototyping is essential. 3D printing helps companies bring new ideas to life and test them in real-world scenarios before mass production.

Sustainable Electronics: As sustainability gains importance, 3D printing allows for the creation of more sustainable electronics. Parts can be designed with reduced material waste and energy consumption in mind.

In these industries, 3D printing is not just a technological advancement; it's a paradigm shift. Its ability to deliver precision, customization, and rapid prototyping is reshaping the way we design, manufacture, and use products, leading to more efficient, sustainable, and innovative solutions across the board.

Choosing the Right 3D Printing Service

Selecting the right 3D printing service provider is crucial for obtaining high-quality replacement parts. Here are some factors to consider:

Expertise: Look for providers with a track record of producing reliable and accurate parts for your industry.

Materials: Ensure the service offers the material that best suits your replacement part's requirements.

Lead Time: Evaluate the turnaround time, especially if you need the replacement part urgently.

Quality Assurance: Inquire about quality control measures in place to guarantee the precision and durability of the parts.

Challenges and Limitations of 3D Printing

1. Material Limitations

While 3D printing is a versatile technology, it does have its constraints, primarily concerning the materials that can be used. This limitation is a crucial consideration when choosing 3D printing for specific applications.

3D printing predominantly utilizes plastic filaments, metals, ceramics, and composites, each with its unique characteristics. However, not all materials are suitable for every application, which can restrict the technology's use in certain industries and scenarios.

Expanding on this, consider the following:

Material Selection: The choice of material for a 3D printing project is paramount. For instance, while plastics like PLA and ABS are cost-effective and widely used, they may not be suitable for applications that require high-temperature resistance or extreme durability.

Limited Material Properties: Each material has inherent properties that determine its suitability. Metals offer high strength, but they might not be ideal for applications that require lightweight components.

Material Compatibility: Compatibility between the chosen material and the 3D printing technology being used is crucial. Some materials work better with certain 3D printing methods, and this can limit material choices.

Ongoing Material Research: The field of 3D printing materials is continuously evolving. Researchers are working on developing new materials to expand the capabilities of 3D printing, but this research is ongoing, and not all industries can benefit immediately.

2. Post-Processing Requirements

After 3D printing, not all parts are ready for immediate use. Many components require post-processing to meet specific quality standards. This step adds time and complexity to the production process.

Here's a more detailed look at post-processing requirements:

Cleaning and Support Removal: In many cases, 3D-printed parts have support structures or remnants of printing material that need to be removed. This can be a meticulous process, particularly for complex parts.

Surface Smoothing: While 3D printing can create detailed parts, the surface finish may not always meet requirements. Additional steps like sanding, polishing, or chemical treatments may be needed to achieve a smooth, uniform appearance.

Painting and Coating: Some applications, such as consumer products or automotive components, demand a specific aesthetic or protective finish. This necessitates painting or coating, which adds another layer of complexity.

Quality Assurance: Post-processing often involves quality checks to ensure the printed part meets the required specifications. This can include dimensional accuracy, strength testing, and other quality control measures.

3. Cost of Equipment

Setting up a 3D printing facility or acquiring the necessary equipment can be a significant financial investment. While 3D printing offers numerous advantages, the cost factor is a considerable limitation, particularly for smaller businesses or individuals.

Let's break down the cost-related challenges:

Initial Investment: Purchasing 3D printers, materials, and associated hardware can be expensive. This is a barrier to entry for businesses that may not have the capital to invest upfront.

Maintenance Costs: Beyond the initial investment, ongoing maintenance and repairs can be costly. 3D printers require regular upkeep to ensure they function optimally.

Skill Development: Operating 3D printers effectively requires expertise. Training employees or acquiring skilled personnel can add to operational costs.

Scaling Challenges: As businesses grow, they may need to invest in more equipment to meet increasing demand. Scaling 3D printing operations can involve substantial costs and logistical challenges.

While 3D printing is a transformative technology with remarkable advantages, it's essential to recognize and address these challenges and limitations. Material restrictions, post-processing requirements, and the cost of equipment are factors that organizations and individuals should carefully consider when embracing 3D printing for various applications. By understanding and mitigating these limitations, it's possible to harness the full potential of this innovative technology.

Conclusion

3D printing services for replacement parts offer a plethora of benefits, from cost-efficiency to customization and speed. With the right materials, expertise, and technology, this innovative approach can revolutionize the way we repair and maintain our machinery. As industries continue to embrace 3D printing, the future promises even more advanced applications and opportunities.