3D Printing : Direct Energy Deposition (DEM) & Electron Beam Melting (EBM)

3D Printing: How Does Direct Energy Deposition (DEM) & Electron Beam Melting (EBM) Fit Into the 3D Printing World?

3D printing has completely revolutionized the manufacturing industry. These new additive processes have opened up new opportunities for manufacturers to create parts with complex geometries, reduce the need for secondary operations like drilling or casting, and eliminate the need for tools and molds.

Direct Energy Deposition (DED) and Electron Beam Melting (EBM) are two unique 3D printing technologies that are often confused with each other due to their similar sounding names. However, they are very different in their approach and capabilities. While they are both additive manufacturing techniques, they have very different requirements and produce very different results.

Understanding these differences will help you choose the most suitable process for your project.

With so many different 3D printing technologies available, how do you know which is right for your application? And what exactly are Direct Energy Deposition (DEM) and Electron Beam Melting (EBM) technologies?

In this blog post, we’ll answer all of these questions and more!

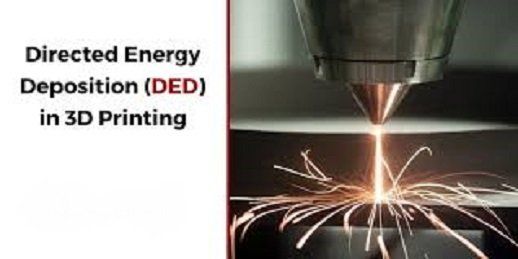

What is Direct Energy Deposition (DEM) 3D Printing?

DEM is an additive manufacturing process that uses a focused laser to create metal parts in a vacuum chamber. During the process, a high-powered nitrogen laser is passed through a photothermic reaction chamber to create an ionized gas. This laser beam is then focused onto a rotating work piece where it is absorbed by the surface and used to melt the metal. In this way, the laser acts as a heat source and a deposition mechanism to melt the metal without the need to bring any material into the vacuum chamber.

DEM is a unique additive manufacturing process that has several advantages over other 3D printing techniques. For example, many metal 3D printing processes require the use of a binder material to hold the metal powder together during the melting process. This can lead to porosity and defects in your final part because the binder is not 100% pure metal and may have some oxidation or contamination issues.

DEM uses pure metals, so there is no need for binders, making it possible to produce parts with less porosity and fewer defects than other additive manufacturing processes. Another advantage that DEM has over other technologies is its ability to create high-strength parts in a single step.

This eliminates the need for secondary operations like machining or welding that are often required on parts made by other metal 3D printing processes.

What is Electron Beam Melting (EBM)?

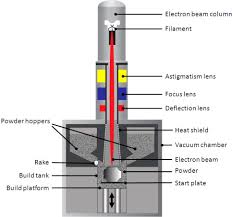

Similarly to DEM, EBM creates parts by melting the metal powder with a high-powered electron beam. However, unlike the focused laser used in DEM, the EBM process uses an electron gun to melt the metal powder. EBM uses a high-voltage electron gun to emit charged particles that are directed towards a rotating metal powder.

This creates an electromagnetic field that draws the metal particles towards the gun, where they are melted together to form a solid part. While the difference between EBM and DEM might seem subtle, the key difference is that in EBM, the metal powder is melted with an electron beam instead of a laser. This means that the manufacturing process is able to work with a much wider variety of materials.

Electron Beam Melting (EBM) uses an electron beam gun instead of a laser to melt metals into a part shape during the additive manufacturing process. The gun passes through a vacuum chamber where it melts metal powder into solid form using an electron beam.

The melted material is then deposited onto a work piece where it begins to cool down and harden before being removed from the chamber as a finished part. EBM technology offers several advantages over laser-based systems including increased energy efficiency, higher deposition rates in shorter time periods, and greater overall.

This allows manufacturers to produce complex geometries and extremely fine details that would otherwise require a mold. When manufacturing with DEM, manufacturers can choose between multiple different metals including steel, cobalt-chrome, stainless steel, and nickel-based alloys.

How Is EBM Used in Manufacturing?

EBM is used to create very large parts with intricate geometries that would otherwise require a large amount of material. This makes EBM an excellent choice for aerospace and automotive applications, where lightweight materials are often required. While EBM does require an investment in machinery, it is a very attractive option for manufacturers who are looking for a wide range of material options.

EBM is able to produce parts from a variety of materials including cobalt-chrome alloys, stainless steel, and nickel-based alloys. EBM is another additive manufacturing process that uses a focused electron beam to create metal parts in a vacuum chamber. During the process, an electron gun is passed through a photothermic reaction chamber to create an ionized gas.

This electron beam is then focused onto a rotating work piece where it is absorbed by the surface and used to melt the metal. In this way, the electron beam acts as a heat source and a deposition mechanism to melt the metal without the need to bring any material into the vacuum chamber. This allows manufacturers to produce complex geometries and extremely fine details that would otherwise require a mold.

When manufacturing with EBM, manufacturers can choose between multiple different metals including steel, cobalt-chrome, stainless steel, zinc-based alloys and more!

How Does DED Work?

DEM works by directing a laser beam into a rotating work piece to produce a localized melt region, while simultaneously cooling the surrounding areas to prevent overheating and distortion. The laser is precisely focused on the surface, and penetrates only a very small distance into the material. As the laser beam travels through the rotating work piece, it is absorbed by the surface, creating a localized melt region that sticks to the rotating work piece.

The laser beam is carefully controlled by a computerized positioning system that focuses the laser in a specific area to ensure that the desired amount of material is deposited. The need to post-process your part, which is a time-consuming and potentially damaging process. This is especially important because DEM allows you to create parts that are difficult to machine, like turbine blades.

Another advantage of DEM over other additive manufacturing processes is its ability to produce parts that are larger than what can be produced by powder bed or wire deposition techniques. Since there is no powder bed and the laser beam can be focused down to a very small spot, it is possible to build large components with complex geometries in a single step.

This makes DEM an ideal technique for producing large metal components that would not be feasible using other additive manufacturing techniques.

How Does EBM work?

During the EBM process, the material is first deposited onto a rotating substrate and then built up layer-by-layer until the part is complete. The substrate is coated with a thin layer of powder, and then a powerful electron beam is directed towards the powder. At high-voltages, the beam penetrates the powder and creates a plasma that causes the particles to fuse together. As the substrate rotates, the part is built up by adding new layers of powder.

Once the part is complete, the excess powder is removed and the part is washed to remove any remaining powder residue.

EBM is commonly used for aerospace parts, medical implants, and other parts that require high-precision, high-strength materials. EBM is often compared to SLM, which is another popular 3D printing process that utilizes a laser to fuse powdered materials together.

While the technology behind these two processes is quite different, the results are comparable. Due to the strength of the materials used, the majority of EBM parts are printed in nickel-based alloys or cobalt-based alloys.

EBM has been widely adopted for industrial applications because of its ability to produce parts with high accuracy and high detail. In addition, the process is very material-independent and can be used to produce a wide range of materials, including metals, plastics, and ceramics.

EBM is mainly used in the production of dental and medical devices, as well as in the aerospace, automotive, and electronics industries

Key Differences Between DED and EBM

As we’ve discussed, DEM and EBM are both additive manufacturing technologies that work by melting metal to create parts. While both processes use a focused laser as the heat source, they are also able to create parts from a wide variety of different materials. The biggest difference between DEM and EBM is that DEM uses a laser to melt the metal, while EBM uses an electron beam. While this might seem subtle, it has a significant impact on the materials that can be used for each process.

Electron beams are capable of melting materials that lasers cannot, like ceramics, plastics, and certain alloys. This makes EBM a much more flexible process than DEM, which is limited to only certain metals. However, EBM also has a higher upfront cost than DEM.

An electron beam has a much smaller wavelength than a laser and is therefore able to heat metals that are normally difficult to melt, such as stainless steel or titanium. The smaller wavelength also means that an EBM system can be much smaller than a DEM system, making it easier to install in manufacturing plants.

Why is Direct Energy Deposition Important?

One of the biggest advantages of using DEM is that it allows manufacturers to produce fine details that would otherwise be impossible to achieve by casting or forging. The advantage that DEM has over other processes is the ability to produce high-quality components with very fine detail. This makes it possible to build parts with a surface finish comparable to traditional subtractive processes and obtain the same mechanical properties.

While DEM is a relatively new technology, there are a number of advantages that make it promising for the future of additive manufacturing. One of its biggest advantages is that it can produce very high strength parts in one step, which eliminates the need for post-processing steps like welding or heat treatment. It can also produce very fine detail and accurate part geometries without requiring additional tooling.

Also, because DEM uses pure metals, there are no concerns about porosity or defects from using binders like other additive manufacturing processes require.

DEM can also be used to create parts that are difficult or impossible to make with other additive manufacturing processes . These include complex geometries and parts with holes, undercuts, and very thin walls. Often times, these parts are made by subtractive methods using traditional machining tools. These processes can be time consuming and expensive because they require additional tooling (i.e. mills).

With DEM, complex geometries can be created without requiring additional tooling and is done in a single step which makes it much more cost-effective than traditional machining processes.

All of these advantages make DEM an excellent choice for creating high-value metal components in aerospace & defense applications such as jet engine turbine blades, landing gear struts, missile components or satellite structures among many others.

Additionally, the deposition process can be used to create parts in materials that would be difficult to cast, such as cobalt-based alloys. Finally, because parts are created without the need for molds, there is less waste in the manufacturing process.

Why is Electron Beam Melting Important?

The wide range of materials that can be used in the EBM process makes it an excellent choice for a variety of industries. While DEM can only be used for a limited number of materials, EBM can be used for nearly any metal, including precious metals like gold and silver.

EBM is also an excellent choice for industries that require high-precision parts, as this process is capable of forming parts with a tolerance of up to 10 microns, which is roughly the width of a human hair.

EBM is also an excellent choice for industries that require parts with low-to-no electromagnetic interference, as no spark discharge is used. Additionally, the process is suitable for industries that require materials that are difficult to form via other methods, as EBM is capable of forming materials like graphite, titanium, and tantalum.

EBM is also suitable for industries that value environmentally-friendly manufacturing, as this process does not release hazardous materials into the environment.

EBM is especially useful for printing metals that are difficult to work with using traditional manufacturing methods. These metals often require high temperatures to melt them, which is not possible with traditional manufacturing methods.

EBM provides an alternative way to fabricate these metals, and the flexibility of this process allows engineers to experiment with new materials that were not previously possible to manufacture.

Should You Use DED or EBM 3D Printing?

Now that you know the differences between DEM and EBM, it’s time to decide which process is right for your application. To help you make your decision, we’ve put together this handy table that compares the two technologies head-to-head based on five different categories.esthe need for secondary operations such as sintering or heat treatment, which can be very time-consuming and expensive.

DEM has been used in a variety of industries from aerospace to dental implants. One interesting application is its use in the production of dental implants. Dental implants are often made from titanium alloys because these materials have excellent biocompatibility; however, it can be difficult for dental labs to produce titanium implants using traditional manufacturing methods because they require several different steps including casting, forging, machining and finishing.

By using DEM technology it is possible for dental labs to produce titanium implants with no secondary operations required; this not only makes it more cost-effective but also reduces the amount of time required from start to finish and minimizes material waste because there is no need for any need to post-process parts, which can be time consuming and expensive.

DEM is an additive manufacturing process that has many advantages over other additive manufacturing processes, but it also has some limitations. One of the biggest limitations is that the laser must be focused onto a rotating work piece in order to melt the metal.

This means that you can only produce parts that are between 0.5 mm and 5 mm thick. Another limitation is that DEM is not currently able to print in non-metallic materials like polymers or ceramics. Despite these limitations, DEM has been used to manufacture a wide range of components including gears, bearings, springs, and more.