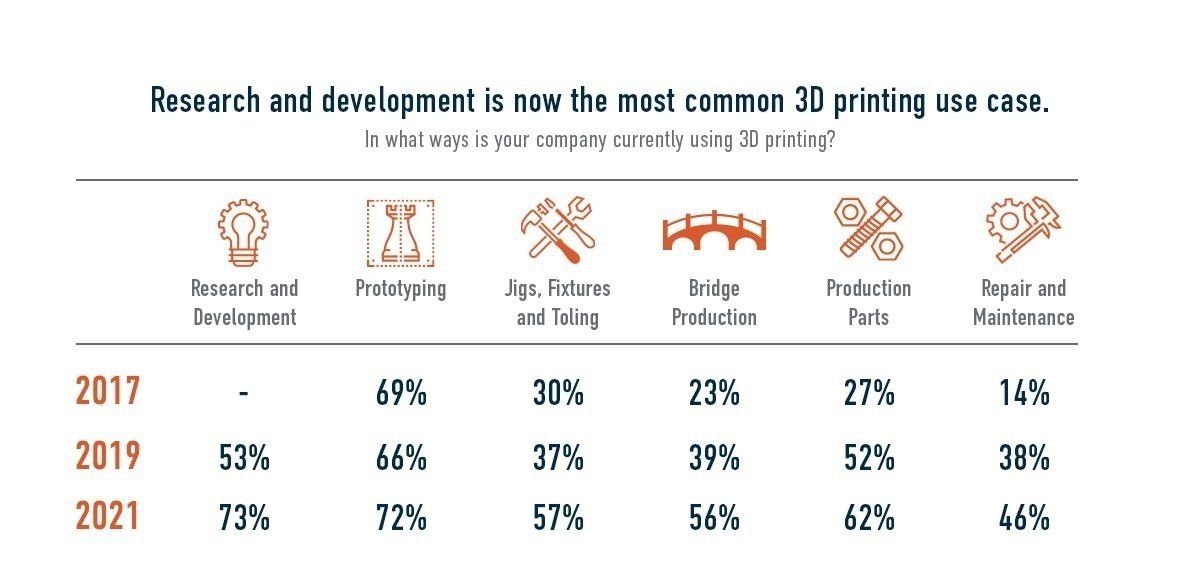

3D Printing Trends | Use Cases for 3D Printing is growing fast

3D Printing Trends

Since its conception, 3D printing has had the potential to transform the manufacturing industry. Benefits include flexibility, design freedom, time-to-market, mass customization, distributed manufacturing, and much more. There are challenges associated with 3D printing, but the results are demonstrating its value.

Time is our most valuable resource today. Increasing competition and changing business models mean companies must shorten development cycles to innovate and implement new ideas quickly and efficiently. The availability of newer, better-performing machines, a broader selection of materials, and the ability to produce 3D printed parts true to their mechanical properties have made 3D printing a significant alternative for design and manufacturing.

3D printers are making it possible for companies to experiment with previously impossible applications. 3D printers will become more accessible as the cost reduces and the speed at which a company can scale mass production increases, thereby transforming the entire manufacturing industry.

3D printing has a very positive outlook for the future. Stakeholders in manufacturing are expecting significant growth for this technology. Ninety-seven percent of manufacturers surveyed expect 3D printing to grow within five years.

The majority of participants expect their companies' use of 3D printing to double in the coming years. Almost half expect their use to double, while four out of ten expect a dramatic increase (five times or more). In addition to the growing acceptance of the practice industry-wide, once again, the accessibility of the technology will drive this growth.

Brands are Enjoying a Wide Range of 3D Printing Benefits

This recent increase in optimism in 3D printing may not be a coincidence, as we rely on additive manufacturing to survive the COVID-19 crisis. As the pandemic spread, companies with 3D printer capabilities jumped at the opportunity to manufacture and scale much-needed but much-needed medical personal protective equipment (PPE), such as respirators and shields. Through the development of new diagnostic equipment and test kits, 3D printing has helped facilitate a secure prototyping and design process.

"Every aspect of the process is further enhanced by having this [3D printing] capability in our facility," concluded John Wahl VI, a tool engineer at Auburn Hills. "The first is time, the second is more creativity, the third is cost and the fourth is materials."

The High Demand for 3D Printing in Automotive industry

The 3D printing is not a technique that has many subjects, but in the foregrenced new approach, the production changes better. Cheaper and more efficient production means a greater choice for prices and consumers cheaper. Since Industries are bonus when demand (and business) increases, this means more work.

The prior production of stationary service parts is built by extraction and manufacturing more materials. The 3D printer represents a single manufacturing room (AM) for each layer. Designers create parts on a computer and send them to a 3D printer, where they inject fused composite materials layer by layer to create the desired object. Currently these are mainly plastic, ceramic and metal powders, but other materials are also under development.

This process represents a new way of seeing for engineers. The ability to create complex 3D objects that form a single unit breaks down design limitations when machining or molding parts. Engineers can design better components without the limitations of manufacturing capabilities. These printers have become cheaper, but many companies do not want to accept skills. This is because it misses the end product confidence. Some people are very late or very difficult, it's hard to get or obtain a lot. Other people cannot exist or lack of workplace. Everything changed.

The automotive and aerospace industries are also facing a number of steps. GE Aircraft has announced that it has already begun producing fuel nozzles made by 3D printers as a unit that is 25% lighter than the old process, which requires the production and assembly of 18 different parts.

Aurora Flight Sciences demonstrated an aircraft made from parts from a 3D printer. It has a wing width of nine feet and reaches a speed of 150 miles per hour, while weighing only 33 pounds.

The automotive industry keeps up. Local motorists left Strati Uncovered, UNI-Body Saver held in AM-AM-AM-Model in these buyers cars who can design their own cars in kiosk and send a file to Microfabrise to achieve.

This industry should rely on 3D printers to make metals. Ability to make such a basis in the bond sector. It is traditionally made of precious metal powders. A company called Xjet has announced that it will launch a printer that uses liquid metal, which makes things faster and cheaper.