A Beginner's Guide to CAD

A Beginner's Guide to CAD for CNC Machining and 3D Printing

Computer-aided design (CAD) software is the foundation of almost every manufacturing business. From small home shops to large manufacturers, companies in every industry use CAD tools to help them digitally design new products before they’re built. CAD software streamlines the design process by enabling you to create digital blueprints of your products before production. It helps smooth out any kinks and imperfections in your ideas before you spend thousands of dollars on materials and machinery.

And that’s just the tip of the iceberg when it comes to CAD for CNC machining and 3D printing. If you’re new to these concepts or exploring new ways to approach your work, this article breaks down everything you need to know about CAD software, how it can benefit your business, and why so many manufacturers use it on a daily basis.

What is Computer-Aided Design (CAD) Software?

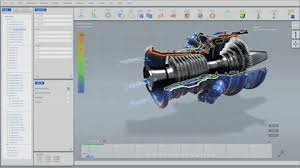

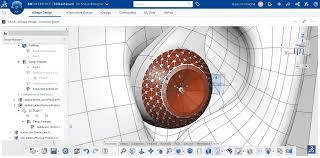

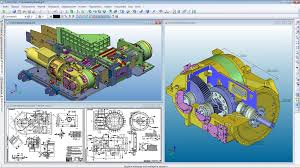

Computer-aided design (CAD) software is a set of digital tools that help you design and create products digitally. You can use CAD tools to design, model, and visualize all the parts and components of a project—including the materials it’s made out of. Computer-aided design software is used in a wide range of industries, from architecture to aerospace. It’s used in almost every manufacturing process, from product design and engineering to marketing and customer service. Typically, CAD software is used alongside other design software, such as Computer-aided manufacturing (CAM) software, computer-aided engineering (CAE) software, 3D modeling software, and more. CAD software is an extremely versatile design tool that can be used to create almost anything. No idea is too big or too small for a CAD designer. From making a new logo to designing a new car, CAD software is used to create just about everything.

CAD software helps you design and create products in a faster and easier way than ever before. It’s an essential tool for any manufacturing business, as it allows you to: Work more efficiently – CAD software allows you to work on your projects from anywhere, at any time, and on any device. You can easily collaborate with other designers who may not be in the same office as you are. This gives you the ability to have constant access to your designs no matter where you are or what time it is.

CAD software also helps increase communication and collaboration between all members of your team—from the CEO down to the interns in the mailroom—and provides them with easy access to project information at all times. This makes it much easier for everyone involved in a project to work together more effectively, without having constant interruptions or having to go back and forth between different files.

Easily share your designs – With CAD software, you can easily share your designs with others through 3D models (also called 3D renderings). This means that anyone on your team—including clients!—can view your product from every angle and see exactly what it looks like before it’s even built. This makes communication with others much more efficient, as well as making sure that everyone stays on the same page throughout the entire project.

CAD software also allows you to share designs with your clients in a more visual way, so they can see exactly how their product will look when it’s finished. This helps them visualize the final product and better understand what they’re paying for.

Easily modify your designs – CAD software is compatible with most other design programs, making it easy to modify existing designs (or start from scratch) without having to switch back and forth between different programs. This makes it much easier to make changes and improve on existing products, or create new ones from scratch.

For example, if you need to make a change to an existing design, all you have to do is open up the file in your CAD software, make the necessary adjustments, then hit “save” and send it back out again! No need for multiple emails or going back and forth between different programs – everything can be done from one central location.

Plus, if you don’t have any 3D models of your product already available (or if yours are outdated), this is another great reason why you should use CAD software—it makes it incredibly easy for you to create renderings of your product before it’s even built! The possibilities are endless…

Get started today – If you haven’t used CAD software before or simply want a refresher course on how this technology can benefit your business, check out the CAD training courses offered by SolidWorks University today!

Benefits of CAD for CNC Machining and 3D Printing

CAD software is an incredibly powerful, yet extremely accessible design tool. It can be used to create nearly anything, from architectural designs, engineering schematics, and product blueprints. CAD software is essential to manufacturers because it helps them completely visualize their products before they’re built. And while CAD tools have become essential in just about every industry, they’re particularly helpful in manufacturing because they can be used to create digital blueprints of the parts, tools, and machinery that go into creating physical products. CAD tools also help manufacturers visualize their designs long before they’re ready to be manufactured. Perhaps they’ve been asked to create a custom product for a customer. CAD software can help them visualize the design in advance, making changes or alterations before any physical materials have been purchased.

This can save manufacturers thousands of dollars in unneeded materials.

CAD software can help save manufacturers time and money. Rather than spending hours manually creating blueprints, engineers can use CAD tools to create blueprints in seconds. This can save manufacturers thousands of pounds in labor costs, as well as reduce production time by weeks or even months.

Some CAD software tools are even able to simulate the manufacturing process, which can help engineers identify potential issues before the product is even built.

What Are the Different Types of CAD Software for Manufacturers?

There are three main types of CAD software that manufacturers can choose from: 2D, 3D and parametric. Each type has its own unique benefits and limitations.

If you’re looking for a simple way to create blueprints without any of the extra features, then 2D CAD software might be right for you.

2D CAD software is ideal for creating 2D blueprints that show a product in detail from one side or at one angle. It’s ideal for creating blueprints of simple products like furniture or other flat items that have only two dimensions.

When it comes to creating digital instructions for production, then 3D CAD software is probably your best bet. 3D CAD software allows manufacturers to create digital instructions that show their employees how to make a part or assemble an entire product from all angles and sides, which makes it easier to build complex products like cars or airplanes.

Parametric CAD software is great if you want certain aspects of your design to change automatically based on certain conditions. For example, if you want your design to automatically adjust its size depending on the size of the materials being used in production, then parametric tools should be right up your alley!

How Does CAD Software Help Manufacturers?

Computer-aided design software is a critical foundation for the design and modeling of manufactured parts. CAD tools can help you design, model, and visualize everything from the materials your product is made from to its dimensions and placement inside the factory. CAD software can also help manufacturers create digital instructions for production. Imagine you’re creating a part for an automobile. Rather than having an engineer manually guide their employees through the process, they can simply create a digital guide with step-by-step instructions inside CAD software.

For example, an engineer could create a digital guide that shows their employees how to embed a specific number of screws into the part. The CAD software will then provide them with the exact dimensions and placement of each screw.

Why Is CAD So Important for Manufacturing?

CAD software has become the industry standard for almost all design and engineering. It’s used on every design and engineering project, from creating architectural blueprints to designing new parts for a jet engine. It’s used by small home shops and large multinational corporations alike. And it’s been that way for decades. CAD has become the standard for almost all design and engineering projects because it allows users to create, visualize, and manipulate designs before they’re manufactured. CAD allows designers to test out different designs, make changes, and save those designs for future reference. CAD also allows users to create a visual representation of their designs.

They can then share these designs with clients and stakeholders on any device—from a laptop to an iPhone. CAD software has become so important because it allows designers to simulate the real-life results of their ideas. CAD allows designers to create an almost identical digital representation of their design before it’s manufactured. This means any potential kinks or imperfections can be ironed out before the product is ever made.

Which Industries Use CAD Software the Most?

Computer-aided design software is used across a wide range of industries, from aerospace and engineering to architecture and product design. However, CAD tools are used most often in the manufacturing sector. CAD software is extremely helpful for manufacturers because it allows them to create and visualize a product before it’s manufactured. It helps them create a digital blueprint of their parts and machinery before they’re completed. This means any potential errors or imperfections can be fixed before any materials are purchased. And it also means manufacturers can create a visual representation of their design, which can be shared with clients and stakeholders long before the product is ready.

CAD software has become so important because it allows designers to simulate the real-life results of their ideas. CAD allows designers to create an almost identical digital representation of their design before it’s manufactured. This means any potential kinks or imperfections can be ironed out before the product is ever made.

CAD Basics: How does it work?

Computer-aided design is a design process that uses computer software to create or modify designs. CAD allows designers to create virtual 3D models by inputting data such as shapes and lines. CAD software is designed to mimic real-world engineering and architectural design workflows—only it allows you to create 3D models inside a digital environment. CAD software allows you to create extremely precise designs, down to the last decimal point. CAD software allows you to create 3D models by extruding 2D shapes and drawing lines. It allows you to create designs from scratch or modify existing ones. CAD software allows designers to manipulate designs (e.g. by stretching, moving, rotating, and resizing components) in order to make necessary changes. CAD software also allows designers to save and share their designs online.

Computer-aided design is widely used in the automotive, aerospace, and shipbuilding industries. It is also widely used in the manufacturing industry to create blueprints and production schematics.

CAD software is a form of computer-aided drafting (CAD) that allows users to manipulate 2D shapes and lines into 3D models. CAD software can be used to create drawings for many different kinds of projects, including:

3D Printing and CNC Machining Differences

3D printing and CNC machining are two manufacturing processes that are often confused with each other. Both are used to create physical products, but they work very differently. CAD software is used in both processes. However, they each have their own sets of design tools and utilities. CAD tools are essentially non-editable, computer-generated models that help you visualize your design. Designers can make changes to their CAD designs, such as adjusting the length of a line or the thickness of a wall. However, they can’t manually change the shape of a component. CAD tools are used in both 3D printing and CNC machining. However, they work very differently. CAD tools used in 3D printing are designed to help you visualize your design. They help you create a precise digital representation of your design, down to the last decimal. 3D printing utilities allow you to add color, materials, and textures to your design. CAD tools used in CNC machining, on the other hand, are designed to help you create a precise digital representation of your design, down to the last decimal. CNC tools allow you to add materials, thickness, and textures to your design.

Which is better? CAD for 3D printing or CNC machining?

CAD software is used in both 3D printing and CNC machining. However, they each have their own sets of design tools and utilities. CAD tools are essentially non-editable, computer-generated models that help you visualize your design. Designers can make changes to their CAD designs, such as adjusting the length of a line or the thickness of a wall. However, they can’t manually change the shape of a component. CAD tools are used in both 3D printing and CNC machining. However, they work very differently. CAD tools used in 3D printing are designed to help you visualize your design. They help you create a precise digital representation of your design, down to the last decimal. CAD tools used in CNC machining, on the other hand, are designed to help you create a precise digital representation of your design, down to the last decimal. CNC tools allow you to add materials, thickness, and textures to your design.