How to 3D Print a 3D Model - A Beginners Guide

How to 3D Print a 3D Model -

A Beginners Guide

3D printing is starting to hit the mainstream and it's not going anywhere. It's important to know how to get started with 3D printing, especially if you're new to this technology. If you want to know what 3D printing is, how it works, and how to create your own 3D model, then this article is for you. We'll walk you through everything from what a 3D printer does, the several types of printers out there, and finally how to use a CAD program such as SketchUp or Blender (with plenty of screenshots) so you can start making your own models today!

there are many online companies that can guide towards everything you need for custom 3D printing projects, from rapid prototyping to small production runs of 3D prints for industrial applications.

In the FDM process we offer both composite plastic and metal 3D printed parts. [ Stainless steel & copper , other metals will follow ].

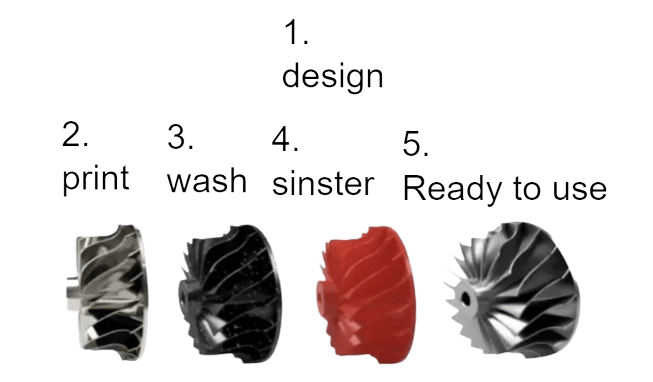

DMLS (Direct metal laser sinstering) , with this process we can offer quality functional aluminum parts.

SLA or 3D resin printing offers a variety of applications such as castable resin, wax-like resin, high-temperature resin,

Tough 2000 Resin is the strongest and stiffest material in our functional family of Tough and Durable Resins. Choose Tough 2000 Resin for strong and sturdy parts that should not bend easily &

Somos WaterShed XC 11122 is a low viscosity liquid photopolymer, which produces strong, tough and water resistant ABS-like parts.

What is 3D Printing?

3D printing is the process of making a real, physical object from a digital model. You can print anything from small figurines to full-sized parts for cars. The 3D printer deposits layers of plastic or metal powder (depending on the material) one on top of each other until you've created your desired shape. The result is an object that has been custom printed just for you.

The first 3D printers were developed in the 1980s, and they were very expensive and not easy to use. Today's 3D printers are much cheaper - some can be purchased for only £300 - and easier to use than ever before.

There are three main types of 3D printers: FDM (fused deposition modeling), SLA (stereo lithography), and DMLS (direct metal laser sintering). The type you choose depends on your needs. FDM is the most common type of printer used today because it's affordable and easy to assemble, but it can't produce as complex designs as SLA or DMLS printers. SLA 3D printers offer more precise prints than FDM models, but they're usually more expensive and require more maintenance because they work by using light to solidify liquid resin into a solid form. DMLS can produce high-quality aluminum parts that resemble traditionally machined components in precision, surface finish, strength, weight, cost-effectiveness, and durability - all with amazing speed !

The Fundamentals of 3D Printing

-What is 3D Printing?

3D printing is the process of using a 3D printer to create a three dimensional physical object. In other words, it’s a type of additive manufacturing technology that builds an item up in layers by depositing material on top of one another.

-How does it work?

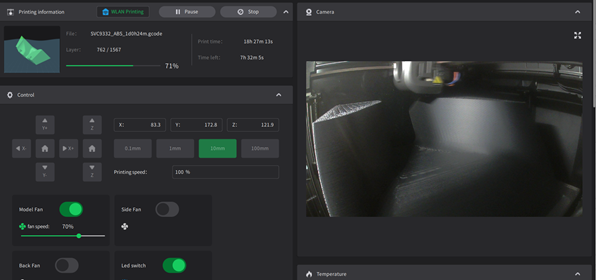

In order to understand how 3D printing works you need to know the basics of how an FDM (or fused deposition modeling) printer works. There are many different types of printers out there and they all work in slightly different ways but for this example we’ll just go with the FDM printer as it’s the most common type.

The first layer is deposited from a nozzle onto your platform and when this layer has finished being built, it moves down and extrudes another layer on top of it. This continues until the object or model is fully formed and then you can remove your printed model from the machine or platform where it was made.

3D Printing Safety

- 3D Printing is a relatively new technology and many people are unfamiliar with it.

- There are many things to consider when printing, from temperature to materials.

- As a result, it's important to have someone who has experience in 3D printing or at least some of the experience in other areas of manufacturing.

- You will also want to make sure your workplace is set up for safety as well as the safety of your product.

- If you're working with lasers, you should have designated laser safety goggles. If you're working with molten material, then you'll need fire resistant gloves and clothing. And if you're using chemicals like acetone, then make sure there's ventilation for those chemicals.

Types of 3D Printers

There are many different types of 3D printers, so it’s good to know what they are before you decide to invest in one.

FDM: These printers use a filament-driven extruder and heat the plastic until it melts and then deposits it onto the build plate, layer by layer. FDM is a fast way to prototype objects - but it's not very accurate or durable.

DLP: DLPs use a projector that shines light through a vat of liquid photopolymer resin onto a surface below. The resin hardens where light shines on it, forming thin slices of a 3D model. DLP printers are precise but slow.

SLA: SLA stands for stereolithography and this process uses an ultraviolet laser beam to solidify liquid photopolymer resin into layers, one thin slice at a time. This process is accurate, but slow and expensive - this type of printer is best for prototypes or small production runs of models with high detail.

MJP: MJP stands for metal jet printing and this process uses inkjet technology to print metal parts by depositing tiny droplets of metal onto layers of binder jetting media (resin). MJP can be used to create functional parts in various metals including steel, copper and aluminium with high precision & accuracy.

FDM Printers

The FDM process can be used to produce prototypes, tooling and production parts with a wide range of materials. For prototyping as well as for low-volume production, the available materials are plastics such as ABS, PETG, PLA and more.

FDM printers have been around for a while now and they're starting to go mainstream. One of the first companies to bring this type of technology to the mainstream is MakerBot Industries. The company has released several models of their Replicator series that are designed for makers of all types.

The price range on these printers is between £1,000-£3,000 with an average cost around £2,000 per unit.

SLA Printers

SLA stands for "stereolithography", and is a 3D printing process where a vat of liquid photopolymer is recoated after each layer, typically with an ultraviolet laser. The result is usually a high-resolution object with very smooth contours. In turn, SLA printers offer the best surface finish.

One of the most popular 3D printers are SLA (stereo-Lithography Apparatus) printers. These use an ultraviolet laser to cure resin to create models.

DMLS (Direct Metal Laser Sintering)

DMLS is a process that turns metal powders into solid shapes by using a high-powered laser to selectively harden the surface of a layer of powder while it's being deposited.

In order to use DMLS, you need to send us your 3D file and tell us what material that should be printed in. That way, we can prepare everything for your project.

As an example, if you are printing with stainless steel, we would need to know the type of stainless steel and which alloy (for example 316L), among other specifications. This information is needed so that our engineers can quickly create the best solution for your needs.

The 3D print will then be made from raw powder using a powerful laser instead of ink with an inkjet printer. The powder is then fused together layer by layer until the object is complete.

Software for Designing and Mods

Bet you thought we were going to talk about CAD software and modeling. Nope, not today! We're going to cover some of the more popular design software for 3D printing that's used for creating models. There are many free options out there, but if you want a more robust tool then keep reading.

Conclusion

3D printing is a versatile method of manufacturing that can create prototypes, models, and even finished products.

The 3D printing process starts with a digital file that describes the shape of the object. A printer then prints the layers of material in the shape of the object, one on top of the other, until the object is finished.

The two major types of 3D printers are FDM (Fused Deposition Modeling) and SLA (Stereolithography Apparatus).

FDM printers work by extruding thermoplastic filament through a nozzle to form layers upon layers of material. This type of printer is most often used for prototyping.

SLA printers use a laser to cure a liquid resin into solid form layer by layer. This type of printer is used for rapid prototyping and for the manufacturing of small quantities. DMLS is also a type SLA printer that uses metal instead of resin.

The software used to design a model is dependent on the type of printer you have. Software for FDM printers includes FreeCAD and TinkerCad. For SLA printers, software includes SureSlice, Rhino and Solidworks.

While 3D printing has become widely used for prototyping and creative use, it is also becoming a popular way to manufacture finished products. 3D printing allows for the creation of complex shapes that would be difficult or impossible to produce using traditional manufacturing methods. The technology has been used to create prosthetic limbs, toys, jewelry, and even houses (tinyhouses).

3D printing is not perfect though. It is still a very new technology that is constantly being improved upon. The biggest drawback so far is the cost of the printers themselves. There are several different types of printers available at varying price points and quality levels. Most of these printers are still out of reach for most individuals and small businesses. They also take quite a bit of time to print an object compared to a traditional manufacturing process.

Another disadvantage is the limited material selection available with current 3D printers. While there are some materials that can be printed with almost any printer (plastic), other materials have more limited options. Metal 3D printers are still very difficult to use, and the quality is often not very good.

The best way to understand the technology is by trying it out for yourself. There are several companies that offer 3D printing services, or you can purchase a printer and start experimenting on your own.

If you have any questions about 3D printing, please leave them in the comments below. I would be happy to answer them!