A Newbie’s Experience with the Inventor 2018 Free Trial: Week Three

I’m nearing the end of my Inventor Free Trial, just 8 days left. This week I focused on honing what I learned in the tutorials and applying those skills to designing something functional.

This week has been the most fun in my entire learning process. I have felt the most comfortable out of all my other times using Inventor this week and I felt like I could actually stand on my own two legs. As I mentioned in last week’s blog, I set out to design something useful and practical for myself. I recently bought a 1999 Jeep Wrangler to have some fun with and decided modeling and 3D printing a new gear shift knob would be just the project for this trial series.

This project was the first one where I fully went off on my own and tried to test what I could do. I had to get my hands dirty and get all the correct dimensions from my Jeep so I could properly model everything. After collecting some preliminary dimensions, I started modeling!

Getting the basic shapes sketched and extruded went by well. Then came all of the fine details like the engraving on the top of the knob, chamfers, fillets, and threads. Other than fairly obvious chamfers and fillets, I proceeded into each one of these tasks slowly, making sure I was grasping the how, what, and why of what I was doing. Going into the engraving/embossing task, I expected it to take a long time for me to figure it out and get it to work right. I was pleasantly surprised as I laid out my text, clicked a button and there was my engraving.

After adding some minor details like the sweep around the knob for added grip and a fillet to blend some edges, my knob was complete! To test myself, I went in and laid it out in a 2D sketch and made everything look pretty. For this model project, I didn’t get too complex, but I’m hoping to iterate over the next week to add some complexities to this project.

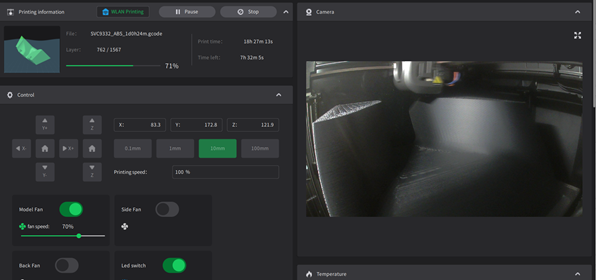

Over this next week, I am going to build on this design and prepare everything for printing. For one of these iterations, I may add a flip up top to the knob and create some interior space to add a switch embed into the knob. If I can accomplish this task, I’m going to wire a push to start button for my Jeep into the gear shift knob in true James Bond fashion. Unfortunately , I will not be building an ejector seat. Maybe I’ll learn Fusion 360 next and build one there.

Tips for Newbies: At this point in your trial, you need to start having some fun with your newfound skills. While the learning track was fun, I didn’t really start enjoying my time with Inventor until I started designing things I liked that would be useful and practical. Play around and explore, you’ll learn the most this way.

The post A Newbie’s Experience with the Inventor 2018 Free Trial: Week Three appeared first on Inventor Official Blog.