A Newbie’s Experience with the Inventor 2018 Free Trial: Week Two

2 weeks into my Inventor Free trial and my proficiency is slowly improving. At this point, improving is all about how much time I put into learning and working at getting better – practice makes perfect. If you missed last week’s blog, you can read week 1 here.

This week I finished up working with assemblies, moved on to learning drawings, and finally finished the built-in learning path. This, of course, means I’m not an expert at Inventor… well not quite. It does, however, mean that my learning from this point forward into my final half of the trial will need to be self-driven and I’ll start experimenting with some of my own designs. I’m expecting the learning to get a little harder now since it will be on me to learn new material. Before I get too far into what’s ahead, let’s talk about how this week went.

Learning assemblies through the learning path made the process quite simple. I was surprised at just how easy it was to create assemblies, animate parts, and all of the other functionality incorporated. For someone with little mechanical background in practice, bringing everything together on the assembly level transformed my designs into something much more tangible. While the rest of the learning has been enjoyable, I feel like learning assemblies has been my favorite part so far.

In both my engineering education and some of my work in civil engineering, I’ve been made fairly familiar with drawings, parts lists, different views, etc. On a personal skills level, spatial reasoning has always been one of my strong suits. Having this background helped me learn the drawing functionality in Inventor with ease and it allowed me to quickly grasp the tutorial steps.

Tips to those just learning: The biggest thing that has kept me from learning more is motivation. You downloaded the trial for a reason, likely to improve your design skills. Set reminders, do whatever it takes to make sure you get on the computer even just a couple of times a week to learn the program. If you can’t follow along with the learning path steps, the online communities are some of the most helpful I’ve ever seen. Search out videos and put in some effort. When you are able to design successfully in Inventor just a few weeks down the road, you’ll thank yourself.

What’s Ahead

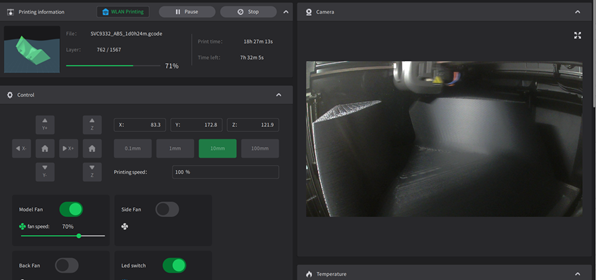

In the next few days, I am going to find a practical project that I want to design a solution for in Inventor. Whether it be a broken latch around the house or something for my old jeep. My goal is to take what I have learned in the learning path and apply it to a practical setting. Whenever I get stuck, I’ll be using the built-in tutorial gallery and getting help from the community. This next week will mostly consist of preliminary design and some troubleshooting as I challenge myself to explore Inventor further. Once my design is completed, I’ll 3D print the parts and hopefully present everyone with a finished product.

The post A Newbie’s Experience with the Inventor 2018 Free Trial: Week Two appeared first on Inventor Official Blog.