What are the strengths and weaknesses of 3D printing?

What are the strengths and weaknesses of 3D printing?

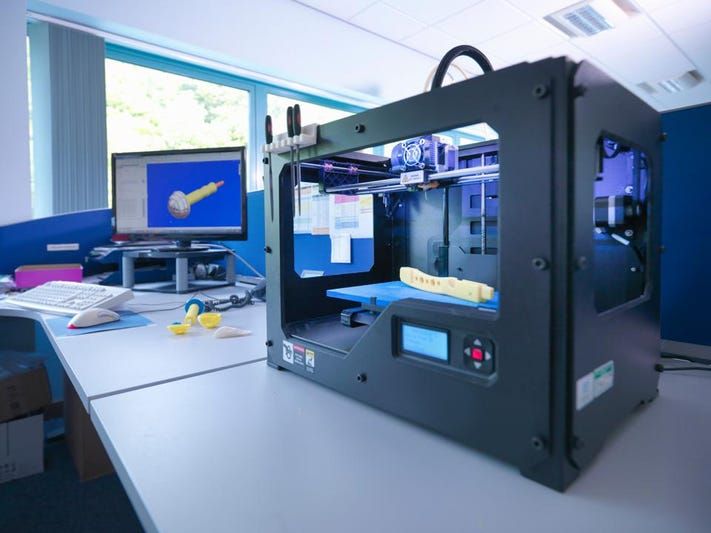

3D printing, also known as additive manufacturing, is becoming increasingly popular with manufacturers. The demand is increasing due to some of the innovative benefits it can provide. Like almost all technologies, it has its own drawbacks that need to be considered.

This page is intended to assist you in the selection process. We discuss all the pros and cons of 3D printing.

What are the advantages of 3D printing?

This manufacturing process has a number of advantages over traditional manufacturing methods. These advantages include, among others, advantages related to design, time and cost.

1. Flexible design

3D printed object

3D printing allows for more complex designs to be designed and printed than traditional manufacturing processes. More traditional processes have design limitations that no longer apply when using 3D printing.

2. Rapid prototyping

3D printing speeds up the prototyping process by producing parts in hours. This allows you to complete each stage faster. Compared to prototyping, 3D printing can complete a part in hours, making it cheaper and faster to create a part, and every design change can be done at a much more efficient rate.

3. Printing on demand

Printing on demand is another advantage because, unlike traditional production processes, it does not require much storage space. This saves space and money because there is no need for bulk printing unless needed.

All 3D design files are stored in a virtual library because they are printed using a 3D model as a CAD or STL file, meaning they can be found and printed if needed. Design changes can be made at very low cost by modifying individual files without wasting old inventory and investment in tools.

4. Strong and light parts

Laser Melting Selective

The main material for 3D printing is plastic, although some metals can also be used for 3D printing. However, elastomers offer advantages because they are lighter than their metal counterparts. This is particularly important in industries such as the automotive and aerospace, where light weight is an issue and can provide greater fuel efficiency.

Parts can also be manufactured to offer specific properties such as heat resistance, increased strength, or hydrophobicity.

5. Speed design and production

Depending on the design and component complex, 3D printing can be printed on objects within hours, which are much faster than edited or edited. Not only manufacture the component that can provide time to save time via 3D printing, but the design process may be very fast by creating STL or CAD files ready for printing.

6. Reduce waste

The generation of components requires only the materials for the same part, with small or stomach waste compared to alternative styles that are made from large pieces of non-recyclable materials. The process is not only recorded in resources, but also reduces the costs of the materials used.

7. COSTING EFFECTIVE

Directly three-dimensional laser

If the process of producing a step provides three-dimensional printing time and therefore costs related to the use of different manufacturing machines. Printers and 3D links can also be defined to track the task, which means that there is no need for operators all the time. As mentioned above, this production process can also reduce material costs because they only use the amount of materials for the same game, with little waste or sumptuous. Purchasing 3D printing equipment can be expensive, but you can avoid these costs by outsourcing your project to a 3D printing service company.

8. Easy access

3D printers are becoming more and more available, and more and more local service providers are outsourcing manufacturing operations. This saves time and does not require high transportation costs compared to traditional manufacturing methods produced abroad in countries like China.

9. Environmental lovers

This process is inherently environmentally friendly as this technology reduces the waste of consumables. However, considering factors such as improved fuel economy with lightweight 3D printed components, the environmental benefits increase.

10. Advanced medical care

3D printer

3D printing is used in medicine to print human organs such as the liver, kidneys and heart to save lives. Further developments and applications are being made in the medical sector, which provides some of the greatest advances in technology. What are the downsides of 3D printing?

As with most other processes, 3D printing technology has its drawbacks, which you should consider before choosing to use this process.

What are the disadvantages of 3D printing?

1. Limited material

3D printing can create items from your choice of plastic or metal, but the selection of available raw materials is not comprehensive. This is due to the fact that not all metals or plastics provide sufficient temperature control to enable 3D printing. In addition, many of these printable materials are not recyclable and very few are food safe.

2. Limited dimensions

Selective Laser Fusion

3D printers now have small print cartridges that limit the size of printable parts. Anything larger should be printed in separate sections and reassembled after production. This can increase the cost and time involved for larger parts as the printer has to print multiple parts to bond the parts together before using them manually.

3. Post treatment

Although large parts require post processing, as mentioned earlier, most 3D printing parts require some form of cleaning to remove the backing material from the building and smooth the surface to achieve the desired finish. Post-treatment methods include water jet, sanding, soaking and chemical washing, air or heat drying, pooling, and more. The amount of post-processing required depends on factors such as the size of the part produced, the intended application, and the type of 3D printing technology used in the manufacture. Therefore, while 3D printing allows for rapid production of parts, production speed can be reduced through post-processing.

4. Bulk

3D printing is a fixed cost, unlike traditional technologies like injection molding, where mass production can be more cost-effective. In the case of 3D printing, the initial investment cost may be lower compared to other manufacturing methods, but once mass-produced, the unit price does not drop like injection molding.

5. Substructure

SLM

3D printing (also known as additive manufacturing) is used to produce parts layer by layer. Although these layers adhere to each other, it also means that they can delaminate under certain stresses or orientations. This problem is greater when manufacturing Fused Deposition Modeling (FDM) articles, while Polyjet and Multijet parts are also more brittle. In some cases it may be better to use injection molding as it creates homogeneous parts that won't fall apart and won't break.

6. Reduction of jobs in manufacturing

Another disadvantage of 3D technology is the potential reduction in human labor as most of the production is automated and done by printers. However, many third-world countries depend on low-technology technological capabilities to maintain economic management, and this technology can be dangerous for these manufacturers by reducing the need for production abroad.

7. Applicable design

Another problem in 3D printing is connected directly to the type of device or process used with some printers with minimal resistance. In other words, the final part means that it could be different from the original design. This can be repaired to elaboration, but should be considered considered to increase production times and costs.

8 Copy protection issues

they are copyright

As 3D printing becomes more popular and more accessible, people are more likely to create counterfeit products and counterfeit products, making the distinction nearly impossible to tell apart. There are obvious problems with copyright and quality control here.

Get more tips on 3D printing

Need help deciding if 3D printing is the right process for you?

email info@mitchellsson.co.uk