3D Printing Prices

3D Printing Pricing: - How Much Does It Cost To 3D Print Per Hour/ Per Square Inch/Per Gram?

Are you curious about 3D printing prices? If you are, you’re not alone. According to a report from Smithers Research, the 3D printing market is predicted to grow to £23.5 billion by 2023. And while there are many different types of 3D printing processes, all of them have one thing in common: They can be quite expensive. Depending on your needs and the materials you use, the cost of 3D printing can range anywhere from a few pence to multiple thousands of pounds per job.

Fortunately, there are ways that you can reduce the cost of 3D printing at home or in your business without sacrificing quality or flexibility. Let’s take a closer look at some tips and tricks for keeping your costs down so that you get more bang for your buck when it comes to using this exciting technology!

New technologies often present a double-edged sword when it comes to adoption. Because of its novelty, new technologies tend to have a high entry cost.

However, the costs will decrease over time with mass adoption and technological advancements. A 3D printer can be an expensive piece of equipment, but with some research you can find one that is within your budget and won’t break the bank. Depending on what features you require, pricing can vary greatly as there are many different types of 3D printers out there with their own pros and cons. Let’s take a look at the different factors that come into play when determining the cost of 3D printing per hour or per square inch!

Factors That Influence 3D Printing Prices.

Most prices quoted for 3D printing services will include the cost of the machine, the cost of the raw materials, and the cost of labor. The equipment cost and material cost are relatively stable, but the labor cost will vary significantly from one service provider to the next. While the service provider’s labor cost will be the most significant, your own labor costs will also be significant when producing parts at home. The quality of 3D printed parts is almost entirely dependent on the skill of the individual who is operating the machine. The time required to produce a part will also depend on the part’s complexity, build size, and the size of the print platform.

If you’re using a low-cost FDM 3D printer for prototyping or producing low-volume parts, you may be able to reduce your costs even further by using co-processing. Co-processing is a technique that’s commonly used in other industries, and it allows manufacturers to reduce costs by using their existing equipment to produce new materials. You can do this by adding a second extruder to your FDM 3D printer so that it can feed a different material through the same head. This means that you can use your existing equipment to produce both your standard 3D printing material and a different substance — like a resin or another polymer.

Material Used

The cost of 3D printing is related to the type of material used. There are many different types of materials used in 3D printing, each with their own characteristics and price tags. For example, ABS filament is cheaper than PLA while Carbon fiber, Nylon, and PETG filaments are more expensive. The cost of 3D printing is also related to the quantity of material used, with larger spools of filament being more economical. Also, the type of machine that you use will affect the cost of 3D printing. Newer models are more expensive than older ones. The type of nozzle that the printer uses may also influence the cost of 3D printing.

If you’re looking to save a few pounds on your next 3D printing job, you may be tempted to go with the lower-cost materials or suppliers. However, this might not be the best idea because depending on what you’re printing, a lower-quality material can actually increase your costs. For example, if you’re printing with a specific type of plastics, the amount of time and energy it takes to melt and fuse the raw materials can impact your costs in a big way. If you go with a cheaper option that takes longer to melt and fuse, not only will you have to wait longer for your parts, but you’ll also have to put more energy into the process.

Filament Diameter

The diameter of the filament that the machine uses will affect the cost of 3D printing. The thickness of the material used in the printer will also affect the quality of the printed parts, so it is best to choose a material with a diameter that is suitable for your application. This process should start with knowing what kind of material you want to print out, but there are many other factors that go into making this decision as well! The wrong diameter can lead not only in printing problems like clogged machines or flawed creations; it could also result from slicing up sections too small (which would then require manual cleaning)or large enough where they jam inside distributor tubes--creating hours worth wasted time while we figure out how get them back together again

Support structure requirements

The support structures that are built in to the 3D model will affect the cost of 3D printing. Some materials require support materials during the printing process because the filament is too thin. The more complex a 3D model is, the higher cost it will have for printing. Support structures that are built into the design strain and warp simple models but can be neglected if you're only looking at larger pieces or objects with fine detail because they don't affect anything outside those limits

Printer platform and build area

The size of the printing platform and the size of the build area will affect the cost of 3D printing. A larger platform will be able to print larger parts, but it will cost more than a smaller platform. A smaller build area will allow you to print smaller parts, but it will also cost less than a larger platform. The size of your 3D printer's print bed will affect the cost and quality. A larger platform can produce larger parts, but it also costs more than a smaller one; if you want to make small objects or actions in particular places then go for this type! The other option is having an extremely spacious build area - which reduces what needs total detail since everything gets layer-upon-layer added at once (less cleanup time).

Maintenance and Repair Costs

Some 3D printers require little maintenance while others will require some routine care and attention to operate smoothly. The type of printer that you use will influence the cost of maintenance. Some printers will require more maintenance than others, while some printers may even need to be sent in for repairs.

Build Size and Complexity

The size of the part and the complexity of the model will affect the cost of 3D printing. 3D Printing offers a number of benefits such as being able to create models with different sizes or complexities, and this can affect how much it costs per print depending on what you're trying produce! The larger your project size (or more complex) -the greater expense will be in terms materials consumption. Another way to reduce your overall costs for 3D printing is to consider doing some jobs in short runs.

Depending on your materials and the design of your printer, it might not be possible to do this with every print job. However, if you’re printing with a photograph-based material like SLA or resin, it’s possible to print smaller quantities with far less waste.

Depending on the design of your printer, you may even be able to print multiple copies of the same part with just a small adjustment or change in the settings. Depending on the materials you’re working with, it might be possible to reduce the size of your print jobs even further by printing with a larger nozzle.

Platform and Software Costs

The software that you use to design the parts will affect the cost of 3D printing. Some software is more expensive than others. For some, 3D printing is an affordable and accessible way to produce models for research or education. However this technology has not yet been deterioration; it’s still quite expensive in comparison with other manufacturing methods like injection molding which can be used on smaller scales without sacrificing quality drastically due their greater affordability compared with traditional machining processes (such as CNC).

The Equipment’s Running Costs

The type of 3D printer that you use will affect the cost of 3D printing. Some 3D printers use more energy than others. A larger printer will use more energy than a smaller printer. Different types of 3D printers have been developed for various purposes. For example, a metal printer uses powder-based materials and produces sharper prints than those made with slabs or FDM machines because it can be more precisely controlled in terms of temperature during print beds which results to better resolution when building up parts layer upon another without any gaps between them. The type of 3D printer you use will affect how much it costs to print. Some printers use more energy than others, so a larger and heavier machine may be better for those who want their finished product in tangible form while smaller models can still produce excellent results without risking too much money on materials or time spent printing out prototypes from concept through production stages!

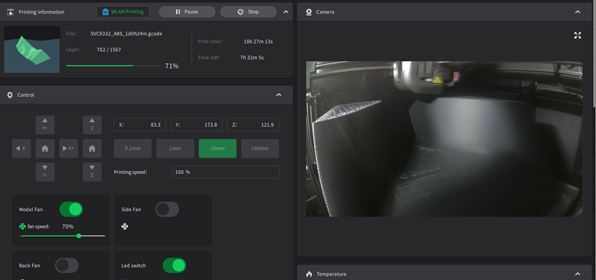

3D Printing Time Calculation

To calculate the cost of printing a part, you need to know the total 3D printing time, the material cost, the machine cost, and the energy cost. The total 3D printing time will depend on the size of the part, the complexity of the model, and the speed at which the printer was printing. To calculate the printing time, you need to know how fast the printer was printing in mm/hour. The material cost will vary depending on the type of material that was used. The machine cost will depend on the type of printer that was used. The energy cost will depend on the type of material that was used.

Subscription Services

If you’re looking to do a lot of 3D printing, one way to reduce your costs is to sign up for a subscription service. Some companies will let you sign up for a subscription service that delivers new materials and/or equipment to your door as soon as you need it. Depending on what you’re printing and what materials you’re using, it’s possible to use a service like this to get the materials you need delivered on a regular basis. Depending on the subscription service, they may even offer discounts on materials that let you save money while getting exactly what you need delivered on a more consistent basis.

Try Out Cloud Printing Services

If you’re interested in exploring new technologies, you may want to try out a cloud printing service. Cloud printing services let you send digital files, such as CAD designs, to a central location where they’re printed and shipped to you in a matter of days. Although these 3D printing services tend to be more expensive than standard FDM printing, they may be worth it if you’re looking for a more consistent, predictable service. Depending on the cloud printing service that you choose, you may be able to upload your files and get a price quote on the spot. You may even be able to see the current status of your job, including the materials and their lifecycle.

3D Printing Service Providers

If you’re looking to get into 3D printing but don’t have your own printer, it may be best to go with a 3D printing service. There are a number of different services available, and they all have their own pros and cons. For example, there are companies like Sculpteo that offer online 3D printing services for a wide range of materials. If you’re just getting into 3D printing and want to test the waters, you might want to start with a service that specializes in printing low-cost materials like plastic. Otherwise, if you’re trying to print with higher-quality materials like ceramics or metals, you’ll want to go with a more specialized service.

Conclusion

We hope that this article has given you a better understanding of what influences the cost of 3D printing. Now that you know about the factors that come into play, you can make more informed purchasing decisions, and get the best value for your money! Moreover, this knowledge will help you calculate the cost of 3D printing for your specific application. Since new technologies are constantly being developed and improved, costs will change over time. When you know what affects the cost of 3D printing, you can keep track of these changes and make adjustments as needed.