Exploring the Amazing Possibilities of 3D Printing

Exploring the Amazing Possibilities of 3D Printing: A Review of Current and Future Trends

The world of 3D printing is on the cusp of a new era, as the technology continues to evolve and become more accessible and cost-effective.

The next decade is set to be a time of great opportunity for 3D printing, with the potential to enter new emerging markets such as commercial space, drones and UAVs.

3D printing has already been used in a range of industries and applications, yet we are now at a tipping point where the technology can be applied to even more ambitious projects.

This is due to advances in materials, software and hardware, making 3D printing more reliable and widely available.

With these developments, it's likely that the next decade will bring the best opportunities for 3D printing to enter new and exciting markets.

Overview of Current 3D Printing Trends

As the technology advances, 3D printing continues to grow in popularity and become more accessible to a wide range of industries and applications.

In the near future, we can expect to see an increase in the number of prototypes and short-run manufacturing (SRM) applications, as well as a wider use of 3D printing in education and training.

Increased use of 3D scanning and 3D modelling software will help to bring new capabilities, such as increased design flexibility and data management.

The adoption of the latest technologies related to the Internet of Things (IoT) and Artificial Intelligence (AI) are also set to make significant contributions to growing 3D printing opportunities.

These trends will help to spur the growth of 3D printing across a range of sectors and for a number of different end uses.

Applications of 3D Printing

3D printing is used in a range of different industries, including aerospace, civil engineering, dental, education, automotive, fashion, healthcare, and more.

3D printing is used in commercial manufacturing to produce parts and components, as well as in product design to create prototypes and new designs.

In education, it is used to create 3D virtual environments, as well as to teach design, engineering, and other skills. Within the healthcare industry, 3D printing is used to produce surgical guides, prosthetics, implants, and other medical devices.

There are even a wide range of artistic and cultural applications of 3D printing, such as 3D printed sculptures, furniture, and other decorative items.

Advances in Materials, Software, and Hardware

As the technology behind 3D printing continues to advance and evolve, it becomes increasingly possible to use more advanced and specialised materials.

New materials, such as high-performance composites, specialty metals, and bioplastics, have been introduced to the 3D printing market over the last few years, making it more practical to produce more complex designs.

New software developments are also enabling more design flexibility, with the ability to produce parts made with a variety of different materials.

This means that 3D printed items can be designed to be lighter, stronger, and more durable, for a wider range of applications.

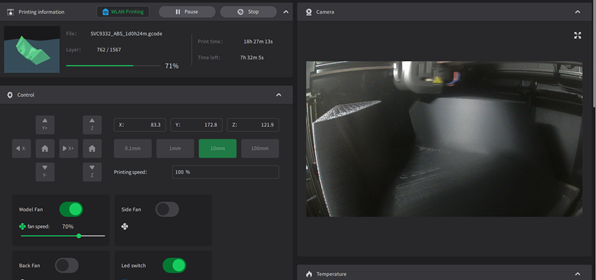

The latest hardware developments have also contributed to improved reliability and usability. Improvements in cooling systems, as well as the development of larger and more user-friendly 3D printers, have made 3D printing easier and more efficient.

Advanced technology such as the implementation of AI in 3D printers is also making it easier to manage complex designs and data.

Potential for 3D Printing in Emerging Markets

As 3D printing becomes more widely used, it's likely that it will be adopted in a variety of emerging markets. Some of the most promising areas in which 3D printing is likely to have future potential include in commercial space, drones and UAVs, and the medical sector.

Commercial space is a new market where 3D printing could play a key role. It's estimated that it could cost £1 billion to send a spool of Kevlar to the International Space Station, which has inspired the development of a new technology: the Laser Net.

This creates a net made out of lasers that could be used to trap space debris. This could open up a new use for 3D printing in space, enabling astronauts to self-produce essential parts and tools. 3D printing could also help to reduce costs in the space industry.

Benefits of 3D Printing in Industrial Applications

One of the most significant advantages of 3D printing is that it is a relatively quick and inexpensive production process. 3D printing allows for the creation of one-off items or small batches, as well as mass production at a lower cost per item.

This means that 3D printed items are often cheaper than comparable items manufactured with traditional methods. Since printed products are not made with moulds, they are also less likely to contain defects, which can cost manufacturers time and money.

3D printed products are also often stronger and more durable, which makes them a great choice for products that need to be long-lasting.

Challenges of 3D Printing

Despite the many advantages associated with 3D printing, there are also a number of challenges that must be considered. These include finding a suitable supplier, managing supply chain issues, managing quality assurance, and securing intellectual property rights. In many countries, the technology has not been widely adopted, making it more challenging to find a company that can produce the designs and deliver the items.

3D printing companies may have limited production capabilities, and it is often difficult to find a nearby supplier that can produce parts at scale. Quality assurance is also a significant challenge, as parts are produced one at a time and not made in large batches.

This means that it can be more difficult to ensure that the parts will meet specifications and work exactly as expected.

It can be complicated to maintain quality control throughout the production process, especially when dealing with large orders.

Intellectual property rights are also a challenge, especially when designers want to protect their work from being copied by other businesses.

It can be difficult to prevent competitors from stealing designs or collaborating with manufacturers to produce similar products.

Conclusion

The world of 3D printing is on the cusp of a new era, as the technology continues to evolve and become more accessible and cost-effective.

The next decade is set to be a time of great opportunity for 3D printing, with the potential to enter new emerging markets such as commercial space, drones and UAVs.

3D printing has already been used in a range of industries and applications, yet we are now at a tipping point where the technology can be applied to even more ambitious projects.

This is due to advances in materials, software, and hardware, making 3D printing more reliable and widely available.

With these developments, it's likely that the next decade will bring the best opportunities for 3D printing to enter new and exciting markets.