Getting Started with Production Manufacturing

Production manufacturing is the creation of components and final products on a large scale intended for sale. The manufacturing phase of product development can be a challenge for first-time entrepreneurs because there are many different options when it comes to finding a production manufacturing partner (both foreign or domestic) along with material selection and the best manufacturing method.

Production manufacturing is the creation of components and final products on a large scale intended for sale. The manufacturing phase of product development can be a challenge for first-time entrepreneurs because there are many different options when it comes to finding a production manufacturing partner (both foreign or domestic) along with material selection and the best manufacturing method.

Deciding on a Domestic or Foreign Manufacturing Partner

Below we discuss the advantages of using a manufacturer that is close to home along with the advantages of partnering with a foreign manufacturing. Ultimately though, the decision to manufacture either domestically or internationally is based on your budget, timeline and customer preferences.

Domestic production manufacturing advantages include:

- Easier Communication. When you and your manufacturing partner share the same language, you are less likely to experience communication barriers and breakdowns. When communication is a challenge, it can be costly for your startup.

- Visit the Facility. When your manufacturer is close, you are easily able to visit the factory and build a trusting relationship with your manufacturing partner.

- Faster Fulfillment. When you don’t have to factor in international shipping, your product will most likely be available much quicker, which means that you can get it to market faster.

- Production Flexibility. Domestic manufacturers are usually able to accommodate smaller production runs. While an international manufacturer might be able to offer a smaller production run, shipping can make it cost prohibitive.

Foreign production manufacturing advantages include:

- Reduced Costs. Manufacturing a product overseas is almost always significantly less expensive than manufacturing domestically.

- Increased Options. In the U.S. manufacturers tend to specialize in the products they can produce, whereas in China a manufacturer might be able to produce a wide range of products. There are also more factories in China which means you have options, helping to keep prices competitive.

- High-volume Capability. International manufacturers excel when it comes to producing high-volume orders in a single production run.

For a detailed list on both the advantages and disadvantages of domestic and foreign manufacturing partners, head on over to our post, “ Domestic v. International Manufacturing for Your Startup ”.

Choosing the Best Material for Your Product

Plastic is a popular go-to material for many new products and inventions—however, there are many more material options to choose from based on your product design, product specifications, intended use and performance maximization. Below is a list of material option considerations that you can take into account during product development and before you head into production manufacturing.

- Fiberglass : Selected for specific applications where products will be exposed to outdoor elements, larger than 4 cubic feet, and when low volume production is required.

- Metals (Aluminum, Stainless Steel, etc.): When requirements dictate that the product materials be metal, casting or CNC are required to produce the parts.

- Neoprene : Used for soft good products used in athletic and training equipment.

- Paper Pulp (recycled paper and cardboard): Used in packaging as well as an alternative for plastic to reduce negative footprint on the environment.

- Plastics (ABS, Nylon, Polycarbonate, HDPE/LDPE): Most commonly used plastics for consumer-based products.

- Plexiglass : Used as an alternative for glass and when applications require a lighter weight material.

- Rubber : Nitrile rubber for automotive and aerospace industries due to its versatility and strong resistance to chemicals, heat, and abrasion resistance.

- Silicone : Products made for food or medical industries. Needs to be Food Grade or FDA medical grade.

- Thermoplastics (HIPS) : Selected for high volume consumer products where application is for single or multiple use.

- Urethane Resin : A good alternative for low volume production of parts when injection molding is not feasible.

Picking the Best Production Manufacturing Method

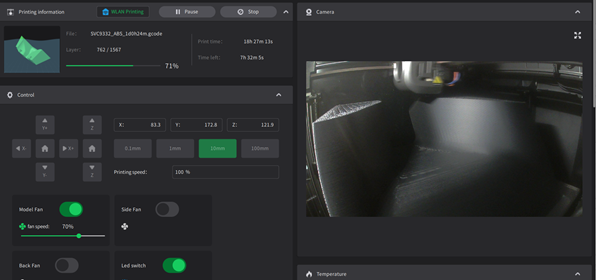

Where once subtractive manufacturing was the only way to manufacture a product—today, that is not the case. Additive manufacturing has advanced to the point where is it suitable for short production runs and is a great complementary technology to subtractive manufacturing. Your product and it’s intended use, will help you decide on the best manufacturing methodology to pursue.

“In manufacturing, subtractive and additive processes often complement each other in the production of tooling, jigs, fixtures, brackets, molds, and patterns. Manufacturers often use plastic 3D printed parts for fast, custom, low-volume, or replacement parts and opt for subtractive metal processes for higher volumes or parts that are subject to more extreme mechanical stress and strain.

Utilizing both additive and subtractive manufacturing results in a hybrid process. This allows product designers and manufacturers to combine the versatility and quick turnaround times of additive manufacturing with the strength of subtractively produced parts.” ( Formlabs )

Read more about combining these two production manufacturing methods in this blog post.

Manufacturing Sourcing Services

Our 3D Innovations team can lead you successfully from idea to production manufacturing and onto commercialization. With trusted manufacturing partners, both domestic and foreign, we are able to provide solutions for low and high volume production manufacturing.

Areas of production cover plastic injection molding, overmolding, silicone molding, urethane molding, pad printing, metal CNC, material sourcing, hardware parts & accessories, packaging (paper, clamshell, paper pulp), and much more.

Have questions about the manufacturing process? Please send us an email at dwight@mitchellsson.co.uk

______

3D Innovations is a Product Development Company – from the 3D Design to a fully functional 3D Prototype & Product.

The post Getting Started with Production Manufacturing appeared first on 3D Innovations.