3D Printing | The Work Before the Print

3D printing is a technology that has the ability to capture everyone’s imagination, however we need to remember that it is, in a sense, a secondary process and a lot of work comes before you start printing. We all see those fantastic time-lapse 3D printing videos floating around the internet, where in a mere minute you can watch a 3D printer bring a product to life. What you can’t see is the design and testing that comes beforehand.

3D printing is a technology that has the ability to capture everyone’s imagination, however we need to remember that it is, in a sense, a secondary process and a lot of work comes before you start printing. We all see those fantastic time-lapse 3D printing videos floating around the internet, where in a mere minute you can watch a 3D printer bring a product to life. What you can’t see is the design and testing that comes beforehand.

Product Design

Before you even get going with 3D printing, you must come up with your design. On the surface this seems simple enough, however one of the benefits of 3D printing is your ability to design shapes without traditional constraints. Less constraints mean that complex geometries can shine. 3D printing gives new meaning to “thinking outside of the box” when it comes to product design.

With 3D printing technology, complex geometries, internal features and built-in interlocking objects with no assembly required are all possible. With these additional design capabilities, 3D printing creates new product design opportunities.

3D CAD File

Once you come up with a design, it’s time to develop it in a CAD program. This CAD file feeds the 3D printing machine the information that it needs to create the object.

“Not only does a CAD file help save time when figuring out all the finer details of a part by looking at the 3D model, but it also allows a model to be magnified and even rotate on any axis to get a full three-dimensional concept of the part, which allows you a greater sense of the product. Using CAD makes it possible to simulate the movement of a part as well.” ( Vista Industrial )

Product Testing

3D CAD has come a long way in recent years. You can design and stress test your product design all right on the computer. CAD simulations let you get a real feel for your product—how it looks, moves and does under pressure. The ability to do this means that you can refine your design before it is ever 3D printed.

On to 3D Printing

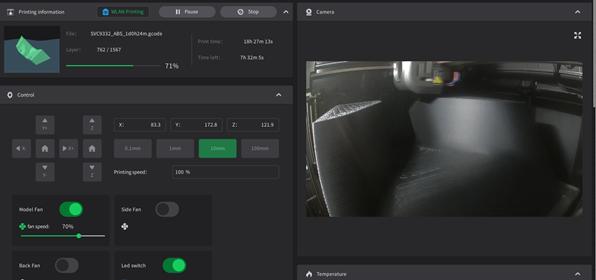

Once you have cleared these hurdles and are happy with your design, it’s then time to head to the 3D printer. Depending on the size of your product, print times can take a few hours.

Fun fact, Oak Ridge National Laboratory (ORNL) and Boeing still hold the record for “ Largest solid 3D-printed item “, with the 3D printed wing trim tool that took 30 hours to make.

Assuming that you aren’t trying to break any Guinness World Records with print size, using 3D printing is a great way to cut down on the time it takes to get a customized part or prototype in your hand. Short turnaround, complex geometries and customization are the main benefits to 3D printing technology and the reason many businesses and entrepreneurs turn to this technology for assistance.

Have additional 3D printing questions? Send us an email at dwight@mitchellsson.co.uk

______

3D Innovations is a Product Development Company – from the 3D Design to a fully functional 3D Prototype & Product.

The post 3D Printing | The Work Before the Print appeared first on 3D Innovations.