ASA 3D Printing Filament: A Comprehensive Guide

Acrylonitrile Styrene Acrylate (ASA) has emerged as a prominent material in the realm of 3D printing, offering a blend of impressive mechanical properties and versatile applications.

This thermoplastic is renowned for its resilience against weathering and UV radiation, making it a preferred choice for both industrial and domestic use.

Developed initially as an alternative to ABS, ASA retains the beneficial traits of its predecessor while enhancing durability and weather resistance.

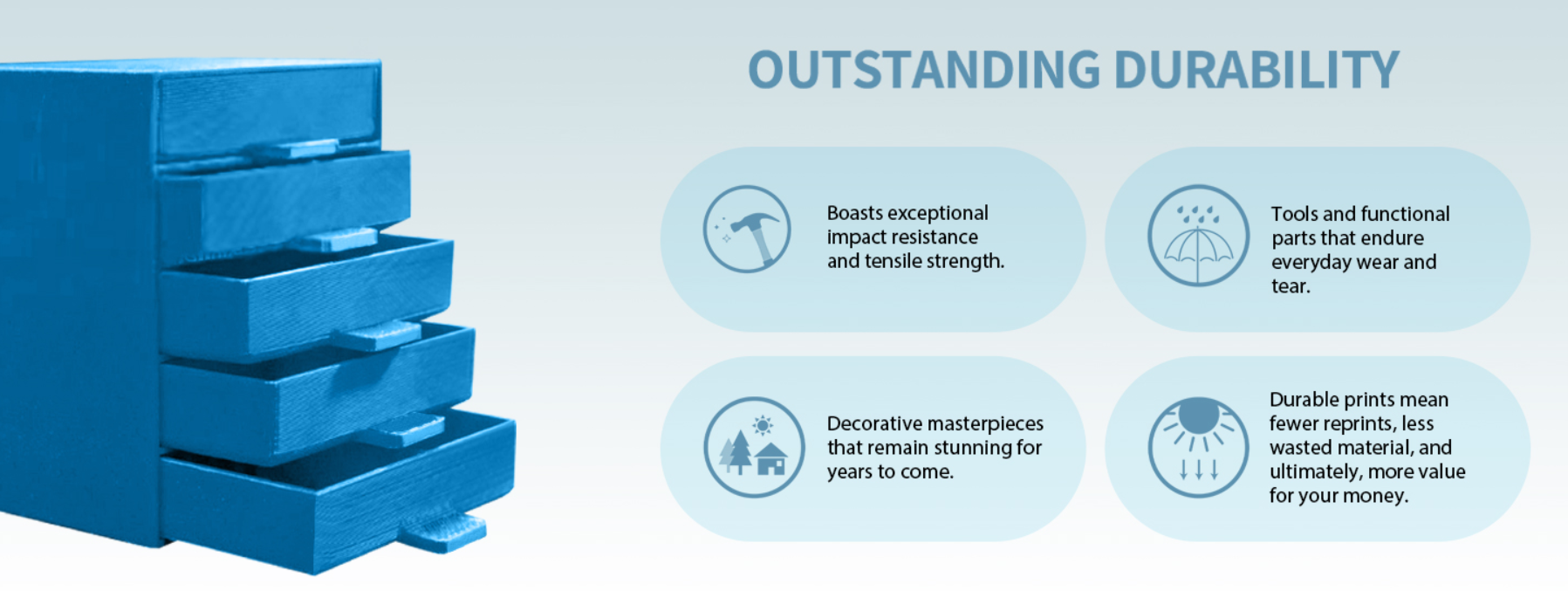

One of the standout features of ASA is its robustness, which is particularly advantageous in the context of mechanical properties.

It exhibits high impact resistance, which is essential for parts that are subject to frequent stress and potential impacts.

Moreover, ASA offers exceptional tensile strength, ensuring that the printed objects can withstand significant forces without breaking.

The material also boasts impressive heat resistance, maintaining its structural integrity even at elevated temperatures, which is crucial for applications that involve exposure to heat.

Its chemical resistance further adds to its suitability for various industrial environments where exposure to harsh chemicals is common.

In the domain of 3D printing services, ASA is frequently utilized due to its excellent print quality and durability.

Companies offering 3D printing services benefit from ASA’s ease of use and the high-quality finishes it provides, which are essential for creating professional-grade prototypes and end-use parts.

Reverse engineering, a process that involves deconstructing and analyzing the components of a product, greatly benefits from the use of ASA.

The durability and precision of ASA make it ideal for creating accurate replicas and models that are critical in reverse engineering applications.

Industrially, ASA is used to manufacture a wide range of products, including automotive components, electrical housings, and outdoor equipment.

Its ability to withstand prolonged exposure to sunlight and adverse weather conditions makes it a prime choice for outdoor applications.

Domestically, ASA is favored for creating durable household items, garden tools, and decorative pieces that require long-lasting resilience.

Commercially, ASA’s aesthetic appeal and mechanical strength make it suitable for producing items such as signage, display units, and custom consumer goods.

To achieve optimal results with ASA, it is essential to fine-tune the settings on your 3D printer, depending on the specific model you are using.

When working with a Bambu Lab 3D printer, it is advisable to set the nozzle temperature between 240°C to 260°C to ensure proper extrusion.

A bed temperature of 90°C to 110°C is recommended to prevent warping and ensure good adhesion.

Using an enclosed build chamber can further improve print quality by maintaining a stable temperature and reducing the risk of drafts.

For Creality printers, the nozzle temperature should be set similarly between 240°C and 260°C, with a bed temperature of around 100°C.

An enclosure or a draft shield is beneficial to mitigate warping and improve the overall print quality.

On Prusa 3D printers, the optimal settings include a nozzle temperature in the range of 250°C to 255°C and a bed temperature of 110°C.

Utilizing a glue stick or a specific bed adhesive designed for ASA can enhance bed adhesion and reduce the risk of warping.

ASA’s environmental advantages are also noteworthy, particularly when compared to other common 3D printing materials like ABS.

ASA’s weather resistance reduces the need for frequent replacements, thereby minimizing waste over time.

Its chemical resistance means that it is less likely to degrade in harsh environments, contributing to longer product lifespans and reduced environmental impact.

Additionally, ASA can be recycled, which helps in reducing the overall footprint associated with manufacturing and disposing of 3D printed products.

In comparison to materials like PLA, which is often touted for its biodegradability, ASA's longevity can be seen as an advantage in applications where long-term durability is crucial.

The reduction in waste due to ASA’s durability and resistance to degradation aligns well with sustainability goals, making it a more environmentally conscious choice for long-lasting applications.

In conclusion, ASA filament offers a multitude of benefits, from its robust mechanical properties to its suitability for a wide range of applications.

Whether you are engaged in industrial manufacturing, domestic crafting, or commercial production, ASA provides a reliable and durable material option.

By optimizing printer settings and understanding the environmental benefits, users can fully leverage the advantages of ASA filament.

As 3D printing technology continues to evolve, materials like ASA will undoubtedly play a pivotal role in advancing the capabilities and applications of additive manufacturing.

Embracing ASA filament not only enhances the quality and longevity of printed parts but also contributes to more sustainable manufacturing practices.

With its comprehensive range of applications and impressive mechanical properties, ASA stands out as a premier choice for 3D printing enthusiasts and professionals alike.

Whether you are reverse engineering a complex part or creating a custom piece for outdoor use, ASA filament delivers the performance and reliability needed to achieve outstanding results.