3D Printing Will Change The World

How 3D Printing Will Change The

World In The Next 10 Years

When it comes to manufacturing and the future of work, many discussions are centered on artificial intelligence, robotics, self-driving cars, and other technological advancements. These topics are certainly important and will continue to grow in significance in the coming years. However, what many fail to recognize is that there is another revolution taking place right before our eyes – 3D Printing. For those who aren’t familiar with what exactly 3D printing is, this technology essentially creates objects from a digital file by melting raw materials layer by layer. Think of a printer that can create almost anything you can imagine out of various materials such as plastic, wood, metal...even food! It doesn’t matter if you’re an engineer creating blueprints or an artist looking for a new canvas; with 3D printing, the possibilities are endless.

3D Printing in Manufacturing & The Working World

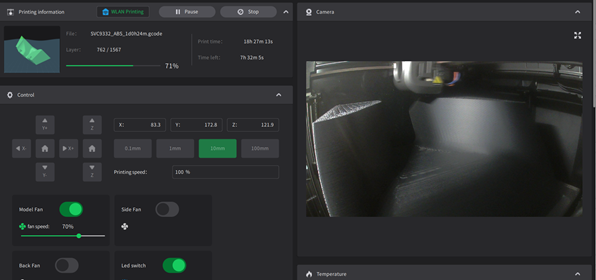

The most obvious and direct impact of 3D printing is its impact on manufacturing. If you’re a manufacturer, you’re likely curious about how to implement 3D printing into your production process and reap the benefits of this technology. Well, wonder no more! First, it’s important to note that 3D printing isn’t a single process but rather a combination of various technologies. There are two main types of 3D printers: Fused filament fabrication (FFF) and stereolithography. FFF printers use a spool of thermoplastic filament to create a new layer of plastic with each pass, while stereolithography works with a vat of liquid resin and a laser. FFF printers are used for industrial applications because they’re more durable than stereolithography printers.

3D Printing in the Developing World

One of the most interesting areas in which 3D printing is being applied is in the developing world. People in developing countries make up the majority of the global manufacturing workforce; however, this isn’t the best option long-term. In fact, many companies have turned to automation over manual labour due to the rising cost of human workers in these regions. Yet, automation comes with a hefty price tag. Therefore, many companies are turning to 3D printing as a more cost-effective solution. However, it’s important to keep in mind that these printers are only as useful as the digital designs that are printed from them. To help combat this, there have been efforts to bring 3D printing to these countries to provide a more sustainable solution. This will allow manufacturers to print parts locally and create a sustainable source of income for these regions.

3D Printing in the Workplace: How Employees Will Be Affected

While 3D printing is set to disrupt the manufacturing industry, it will undoubtedly also have an impact on the employee experience. When manufacturers can produce a wider range of products more quickly, the supply chain will be drastically transformed. This will impact the way that work is done in the office for both management and employees. Managers will have less oversight over their supply chain and will be more concerned with managing a business as a whole. Employees, on the other hand, will be able to more easily access the materials they need to complete their work. This is because 3D printing will allow businesses to produce the supplies they need without having to store them in a warehouse. This will be especially impactful for those in the medical and construction industries.

3D Printing In The Workplace: Past, Present, and Future

To truly understand how 3D printing will impact the workplace, it’s important to look back at how things were done in the past. Before digital design and manufacturing (DM) software was introduced, employees used design drawing systems (DDS) to communicate their designs to engineers. This meant that the design had to be translated and scaled to the correct dimensions on paper. Once the engineer received the design, they would input it into a computer and use 2D CAD software to create a 3D model. This model was then sent to the manufacturer for production. If a change was needed, the engineer would have to go through the whole process again. Now, thanks to DM software, the design is sent to a 3D printer to create a 3D model from the digital design. The engineer can then make changes to the design electronically, which is sent to the 3D printer to create a new model.

3D Printed Houses Are Around The Corner

If there’s one thing we can be sure of, it’s that the world will look very different in the next decade. That’s because in addition to traditional manufacturing, 3D printing is being applied in new industries such as architecture. A company called New Story created a technology that prints houses out of concrete. They ran an experiment in which they built a house in Haiti out of concrete, and it withstood the hurricane that hit the region when many other homes were destroyed. This experiment proves that the technology is already mature enough to be used in construction. What’s more, the company is looking to expand its operations and build more houses in Haiti in the future.

Conclusion

These are exciting times and the future is coming at us faster than ever. With ever-increasing technological advancements and more companies using 3D printing, it’s clear that this technology is here to stay. There is no question that 3D printing will change the world as we know it and revolutionize the way we work. The only question is: are you ready for the changes to come?