3D Printing: Why it is Important and How it Impacts Society

Why it is Important and How it Impacts Society

3D printing is one of the most exciting new technologies. It’s a process that creates solid objects from digital blueprints.

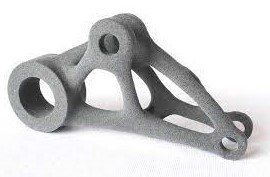

3D printing is also called additive manufacturing, because it builds up layer-by-layer to produce finished objects.

We live in a world where everything has become digital and almost everything we use on a daily basis comes with an app for that. Even our houses are getting smarter and more connected every day.

We have driverless cars, virtual assistants, drones, cameras on the palm of our hands, and so much more.

The technology sector is growing faster than ever before with new innovations coming out almost every single day.

Perhaps one of the greatest examples of this can be seen in the field of 3D Printing Technology – something which is set to change our lives even further in the years ahead.

How does 3D Printing impact Society?

3D printing has come to stay. That's certain. As with every huge technology shift, there's a ton of hype and uncertainty about what the new technology actually does, how it will impact the market, and how it will change people's lives. In some regards, 3D printing is no different.

But as with every technology, there are some very valid reasons why this is so important. Some of which we will go through in this article.

3D printing is a revolutionary technology that enables people to create products by printing layer upon layer of material.

The technology has evolved over the years and is now being used in a host of industries and applications. It has the potential to change the way people make things and to disrupt traditional manufacturing.

Why is 3D Printing so important today?

The short answer is, because it allows the creation of products and items that were previously impossible to make with existing manufacturing technologies. Because of this, the technology is often referred to as “additive manufacturing.”

While traditional manufacturing methods involve cutting or shaping materials by removing pieces from them (such as by carving out pieces from a block of wood or molding clay into a desired shape), additive manufacturing is used to create three-dimensional objects by depositing materials in layers.

With 3D Printing, you can create almost anything, from a full scale home, to a car engine, to a replacement organ for the human body.

It really opens up the potential for new products, new designs, and even new business models.

What is the connection between 3D Printing and 3D Modeling?

3D printing is a kind of digital manufacturing, where a digital model is “printed” out to create an object. But, before an object can be 3D printed, it must first be modeled digitally.

If you’ve ever used computer-aided design software (CAD), you know that modeling software is essential to creating a digital representation of an object. In other words, the 3D modeling software is responsible for creating a digital file that can then be printed out via the 3D printer.

These are not just virtual models that exist solely on a computer screen. Rather, these are actual, physical objects created using 3D modeling software.

3D Printing in Construction and Manufacturing

Due to the fact that 3D printing allows for an unprecedented level of customization, it is no wonder that the technology is being used in the construction industry.

Construction workers who use 3D printing to create custom building materials can create buildings with more aesthetic appeal and less structural risk. In addition, the buildings can be designed to suit the specific needs of each client.

For example, a hospital might use 3D printing to create customized building materials that are designed to withstand the high volume of foot traffic in its emergency room.

These construction materials might include tiles that are designed to resist bacteria or a roof made of materials that are resistant to high levels of rainfall.

3D Printing in the Automotive Industry

The automotive industry has long been considered a forerunner in the implementation of new technological innovations. In fact, some of the earliest uses of computer technology in the mid-20th century were in the automotive sector.

Automakers have long used computer-aided design technology to design their cars and even their entire production lines. And now, they are turning to 3D printing to produce certain parts.

The most notable example of 3D printing in the automotive industry is the investment that Ford has made in the technology. Ford recently purchased a minority stake in Carbon3D, a California-based company that specializes in 3D-printing carbon fiber.

Specifically, Ford is using the technology to create more intricate engine components and even end-use parts for its vehicles.

3D printing has been used for many years to make prototypes, but now it is being used to make finished products, such as earrings and handbags. Chinese companies are using 3D printing to make parts for cars and planes.

Some car parts can be printed in a few hours while others take a few days. These parts are as strong as traditional car parts and are used in driverless taxis. Computer-controlled machines build planes with parts made by 3D printers.

The machines make all parts of the plane and put them together. Manufacturers use 3D printers to make strong, customized products.

They can make a shoe in a size 40 and make it last longer than a shoe made in a size 12. This process is called mass customization.

3D Printing in the Healthcare Industry

The healthcare industry has also benefitted significantly from the use of 3D printing. Medical professionals can use the technology to create custom items, such as equipment, prosthetics, and even implants.

Medical professionals can also use 3D printing to manufacture pharmaceutical drugs with the exact accuracy, dosage (amount), and purity required. This is important, because it allows drugs to be produced in exact quantities, which can reduce the overall cost of manufacturing and enable the production of drugs in remote locations.

3D printing is being used to make medical devices, including surgical tools, artificial body parts, and prosthetics. It speeds up the process of making devices and makes them more exact. It offers an alternative to people who have allergies to certain materials.

A dentist can create a 3D model of a patient’s teeth, revealing areas that may need attention. The model can be printed in different sizes to fit the patient.

It also helps a dentist show a patient the problem areas in his or her mouth by taking an accurate and clear picture of the teeth.

Scientists are using 3D printing to create a wide variety of medical devices, including artificial organs and blood vessels, customized medical tools, and medical implants.

3D Printing in The Food Industry

The food industry has also benefitted significantly from the use of 3D printing. In the same way that food manufacturers can create edible products designed to suit the needs of specific dietary restrictions, they can also create products designed to meet the needs of other special populations.

For example, food manufacturers could create 3D-printed products designed to be visually appealing to children with special needs.

Food manufacturers can also use 3D printing to create special tools and utensils designed to be visually appealing to seniors or people with special needs.

3D printing is being used to create food in several ways. The first way is by printing ingredients, such as chocolate and pasta, with ingredients already mixed together. Another way is to print the mixture itself while adding ingredients, such as a milkshake with different flavors.

A third way is to print food already prepared, such as a pizza or a bowl of noodles. In the medical field, doctors are using 3D printers to make artificial organs and bones, such as joints and bones.

They also use 3D printers to make medical tools such as needles and sutures.

Conclusion

3D printing has become so important in society because it allows for the creation of products and items that were previously impossible to make with existing manufacturing technologies.

As this technology continues to advance, it is likely that many people’s lives will be significantly improved.

However, it is important to remember that this technology is not a cure-all. It is important to keep things in perspective, and to recognize the limitations of 3D printing.