3D Printing Service

HYPERSPEED BATCH 3D PRINTING -

12 X FASTER THAN TRADITIONAL FDM

Batch Size : 2 - 1000

Price Breaks for large Batches

Cost Calculator

Understanding INFILL Percentages:

All 3D Printed items with a default infill % of 20% means that the end product is 80% hollow. The more infill that you select for your product will determine the strength of the end product . A 3D Printed item that has 100% infill will mean that it is a solid piece of plastic but the cost of printing will increase as more material will be used and it will take longer to print than if it was 20% infill.

Before increasing the infill percentage ask yourself :

- What forces are acting on the product that would require greater strength

- Will the item work as required with 20% infill or will it need to have more internal material to be able to last longer.

If the end product is a miniture or a display item then 20 % infill is more than enough.

Remember the higher the infill % the higher the cost per unit.

We offer price breaks for batch sizes, the discounts are automatically calculated via our Cost Calulator.

The discounts are as follows:

- QTY >= 2 Units = 8% discount

- QTY >= 10 Units = 12% discount

- QTY >= 50 Units = 17 % discount

- QTY >= 100 Units = 20% discount

- QTY >= 500 Units = 25% discount

- QTY >= 1000 Units = 30% discount

Contact Us

We will get back to you as soon as possible.

Please try again later.

If you are an industrial 3D printing customer based in the United Kingdom, United States of America or Europe, Mitchell and Son's 3D printing service is the perfect choice for you.

We provide 3D printing on Demand services for all three regions, with our 'Instant Quote' system providing you with a quote for your next 3D printing project in no time.

Not only that, but you can also choose from an extensive selection of materials, each with its own unique characteristics, so you can be sure that you are getting the exact product you want for your project.

Our 'Instant Quote' system takes out the hassle and time-consuming process of finding the right 3D printing solution, leaving you free to focus on your project.

So what are you waiting for? Get started on your next project today!

excellent customer service when requested at anytime during business hours 8am-5pm Monday - Saturday

Some less common types of 3d printing materials that we offer are

- Resin 3D Printing : Tough2000, Wax 3D Print, etc

- Metal 3D Printing: Stainless Steel, Brass, Copper,Aluminium, etc

- Full Colour 3D Printing: Sandstone, Plastic, etc

- Plastic Matarial : Carbon Fibre, ASA, NYLON-CF, Polycorbonate, Glassbend, etc.

When you're on the lookout for a reliable 3D printing on Demand service in your vicinity, your search ends here with our online 3D printing service.

Our cutting-edge additive manufacturing technology guarantees that you'll receive the utmost quality parts available in the market today.

Our swift prototyping process enables us to swiftly and efficiently produce plastic models and metal spare parts, ensuring that you never have to go without the essential product you require.

Moreover, with our online quote software, you'll receive an accurate price quote in no time, ensuring that you're getting the best value for your investment.

But that's not all - we invite you to stay updated with our latest offerings and innovations by following us on Instagram. We understand the importance of keeping our customers informed and engaged.

Our online 3D printing services are the ultimate solution to alleviate the shortage of spare parts in various industries, including but not limited to the automotive sector.

With our state-of-the-art technology and unwavering commitment to excellence, you can rest assured that you're receiving the highest quality parts, no matter where you are in the world. Don't forget to follow us on Instagram to stay connected with our journey of innovation and quality assurance.

FREQUENTLY ASKED QUESTIONS ABOUT 3D PRINTING

-

What factors influence the cost in online 3D printing quotes?

The cost of 3D printing is influenced by material choice, model complexity, the technology used, the amount of required support material, post-processing needs, and the volume of the print.

The amount of infill also plays a role in the cost because the higher the infill % the more material is required and the longer time it takes to print this increases the cost per unit.

-

How do different 3D printing materials affect the final product?

View Materials

View MaterialsEach material offers distinct properties: plastics are versatile and economical; metals are durable and suitable for high-strength parts; resins provide high detail and smooth finishes, affecting the application and performance of the final product.

-

What are the most commonly used 3D printing methods and their advantages?

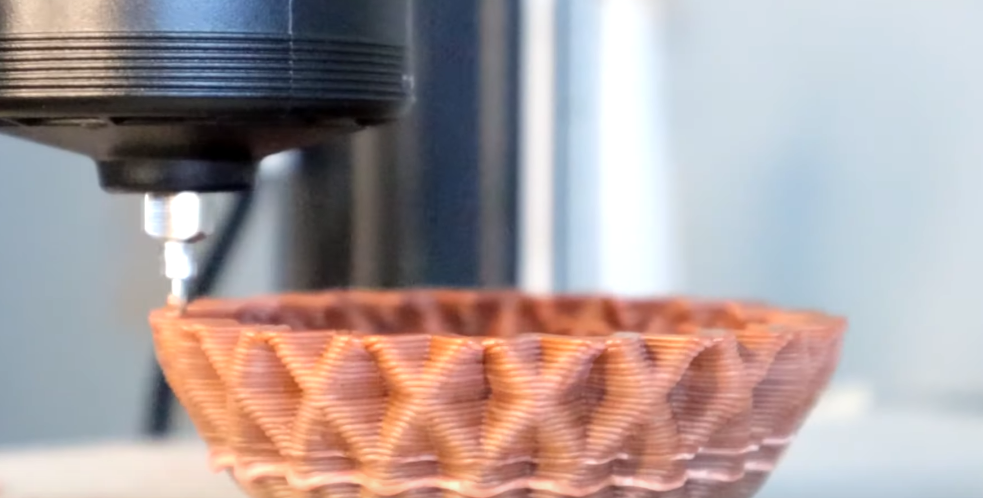

FDM (Fused Deposition Modeling) is cost-effective for basic prototypes; also because the technology is clean it is often used in homes and schools.

SLA (Stereolithography) offers high precision and fine detail. This is a Resin based technology and can be messy, depending on the type of resin its always advised to use in a ventolated area.

SLS (Selective Laser Sintering) allows for complex geometries without support structures..

-

How has 3D printing technology evolved in the last decade?

Advancements include increased printing speed, expanded material options, improved precision, and the integration of AI for better design and manufacturing processes.

We are seeing companies like Creality and Bambulab intergrating AI into the machines which helps detect errors while printing by use of camera's. This is a massive benifit as it stops the machine workign when something goes wrong which means less wasted materials.

-

In what ways does 3D printing contribute to local economic growth?

It reduces the need for imports by localizing production, creates new small business opportunities, encourages innovation through easier prototyping, and decreases the cost of manufacturing.

The biggest way in which to grow the local economy is to enable the circular movement of cash within a local area. So the biggest way is that small to meduim sized business no longer need to contact manufactuers in India or China and can put the maoney back into thier local economy.

-

What are the limitations of 3D printing technology today?

The limitations to 3D Printing can be the size contraints as the largest size desktop type printers are around 350 x 350 x 410 mm.

There are mauch larger formate FDM printer but then the cost of the printer is the limiting factor.

Resin , Metal and MJF printer formates are smaller than that.

-

Can 3D printing materials be recycled, and how?

Many 3D printing materials, especially thermoplastics used in FDM, can be recycled by grinding them into pellets and reusing them in new prints, though this can reduce the material's performance quality over cycles.

There are a number of companies in the UK that recycle filament

-

What are the safety concerns associated with 3D printing?

Safety concerns include exposure to harmful fumes, particularly from melted plastics or metals, potential burns from hot printing components, and the risk of fire from equipment malfunction.

-

How is 3D printing used in medicine?

It's used for creating custom prosthetics, dental implants, and even complex, patient-specific organ models for surgical preparation.

-

What role does software play in 3D printing?

Software is crucial for designing models, converting designs into printable files, and managing printer operations. Advances in software also enable more complex geometries and higher quality prints.

-

How can traditional manufacturers integrate 3D printing into their processes?

Manufacturers can integrate 3D printing for rapid prototyping, custom tooling, and production of complex parts that are too costly or difficult to make with traditional methods.

-

What are the environmental impacts of 3D printing?

Positive impacts include less waste production compared to subtractive methods and the potential for using renewable or recyclable materials. However, energy consumption and the use of non-biodegradable plastics can be concerning.

-

What advancements in 3D printing materials are on the horizon?

Button

ButtonFuture advancements may include the development of new alloys and advanced polymers designed specifically for 3D printing, which could offer enhanced mechanical properties and functionality.

-

How does 3D printing facilitate rapid prototyping?

It allows for the quick production of prototypes directly from digital models, significantly speeding up the design and testing phases of product development.

OUR MISSION

For the automotive and manufacturing industries in the UK, USA, and Europe, 3D printing shops near you are the perfect solution for finding spare parts quickly and easily.

Our online service offers an instant quote, so you can find out the exact cost of the part you need in an instant. With our state-of-the-art machinery and experienced staff, you can be sure that whatever spare part you need, you can get an exact replica with all the relevant dimensions that will fit into place in no time.

This ability to access 3D printing services from anywhere in the world reduces the shortage of spare parts in the manufacturing sector, including the automotive industry.

So don't wait any longer, if you need a spare part for your vehicle, appliance, or any other product, our 3D printing shops are here to help.

For years, finding replacement parts for an old vehicle could be a real challenge. You might have to search for days or even weeks to find the right part, and even then it might not be an exact match. But with 3D printing, that's all changed.

Now you can create custom parts that are designed specifically for your make and model.

Replicating Spare Parts in the UK, we can create a 3D print file of the part you need. This file can then be used to produce the part using a resin printer.

Metal 3D printing can also be used to create parts that are stronger and more durable than those made with resin.

So when you need a replacement part, we can provide you with an instant quote and have the part 3D printed and shipped to you as soon as possible.

Industries

About Us

All Rights Reserved | Mitchell and Son Additive Manufacturing Ltd | Registered Company in England and Wales | Company Number : 12038697

| Public Liability Insurance no. 14615097

Insurer: AXA XL